Carboxymethyl chitosan band-aid and preparation method thereof

A carboxymethyl chitosan and band-aid technology, which is applied in medical science, dressings, bandages, etc., can solve the problems of low preparation efficiency, long preparation time and complicated process, and achieve the effect of excellent air permeability and liquid absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

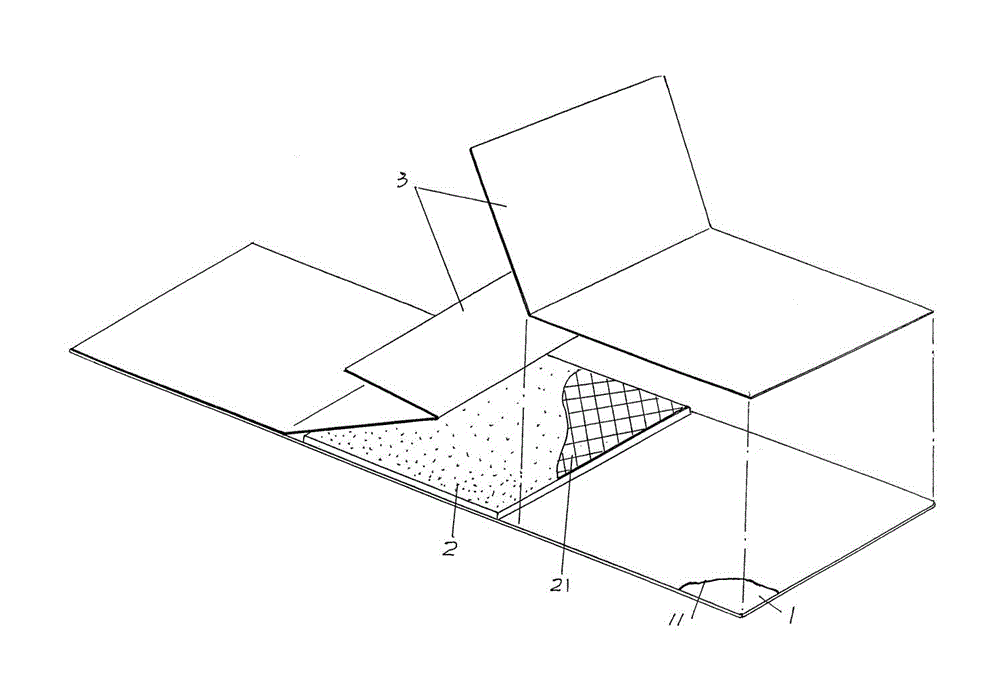

[0025] preparation figure 1 The steps of the carboxymethyl chitosan band-aid of the shown structure are as follows:

[0026] A) To prepare carboxymethyl chitosan fiber non-woven fabric, the carboxymethyl chitosan fiber with a fineness of 2.2-3.5dtex and a length of 4-8 cm is opened by an opener, carded by a carding machine and laid in turn After machine-laying, the net is needle-punched by a needle-punching machine to obtain a wound protection layer 2 made of carboxymethyl chitosan fiber non-woven fabric with a grammage of 120g / ㎡;

[0027] B) Composite, put the wound protection layer 2 made of carboxymethyl chitosan fiber non-woven fabric obtained in step A) and the anti-adhesion film 21 with a gram weight of 20g / ㎡, that is, a mesh-shaped isolation film, together in a composite On the discharge rack of the machine, and the side of the anti-adhesion film 21 corresponding to the wound protection layer 2 is introduced into the compound roll of the compound machine under the sync...

Embodiment 2

[0031] Only change the gram weight of the carboxymethyl chitosan fiber non-woven fabric in step A) to 70g / ㎡; change the gram weight of the anti-adhesion film 21 in step B) to 15g / ㎡, and change the composite temperature to 115°C, change the pressure of the composite roll to 0.5MPa, change the line speed of the composite roll to 8m / min; change the width of the strips in step C) to 1cm; change the matrix in step D) The width of layer 1 and peeling layer 3 are both changed to 1 cm, the thickness of adhesive layer 11 is changed to 0.1 mm, and the weight of peeling layer 3 is changed to 60 g / ㎡. All the other are the same as the description to embodiment 1.

Embodiment 3

[0033] Only change the gram weight of the carboxymethyl chitosan fiber non-woven fabric in step A) to 90g / ㎡; change the gram weight of the anti-adhesion film 21 in step B) to 18g / ㎡, and change the composite temperature to 110°C, change the pressure of the composite roll to 0.4MPa, and the line speed of the composite roll to 6m / min; change the width of the strips in step C) to 1.9cm; change the matrix layer in step D) 1 and the width of the release layer 3 are both changed to 1.9㎝, the thickness of the adhesive layer 11 is changed to 0.3㎜, and the gram weight of the release layer 3 is changed to 80g / ㎡. All the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com