Spark plug

A spark plug and shaft hole technology, applied in the field of spark plugs, can solve the problems of weak bonding between the resistor body and the sealing layer, the diameter of the resistor body sealing layer becomes thinner, and the load life performance is reduced, so as to achieve improved load life performance, excellent load life performance, The effect of suppressing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108]

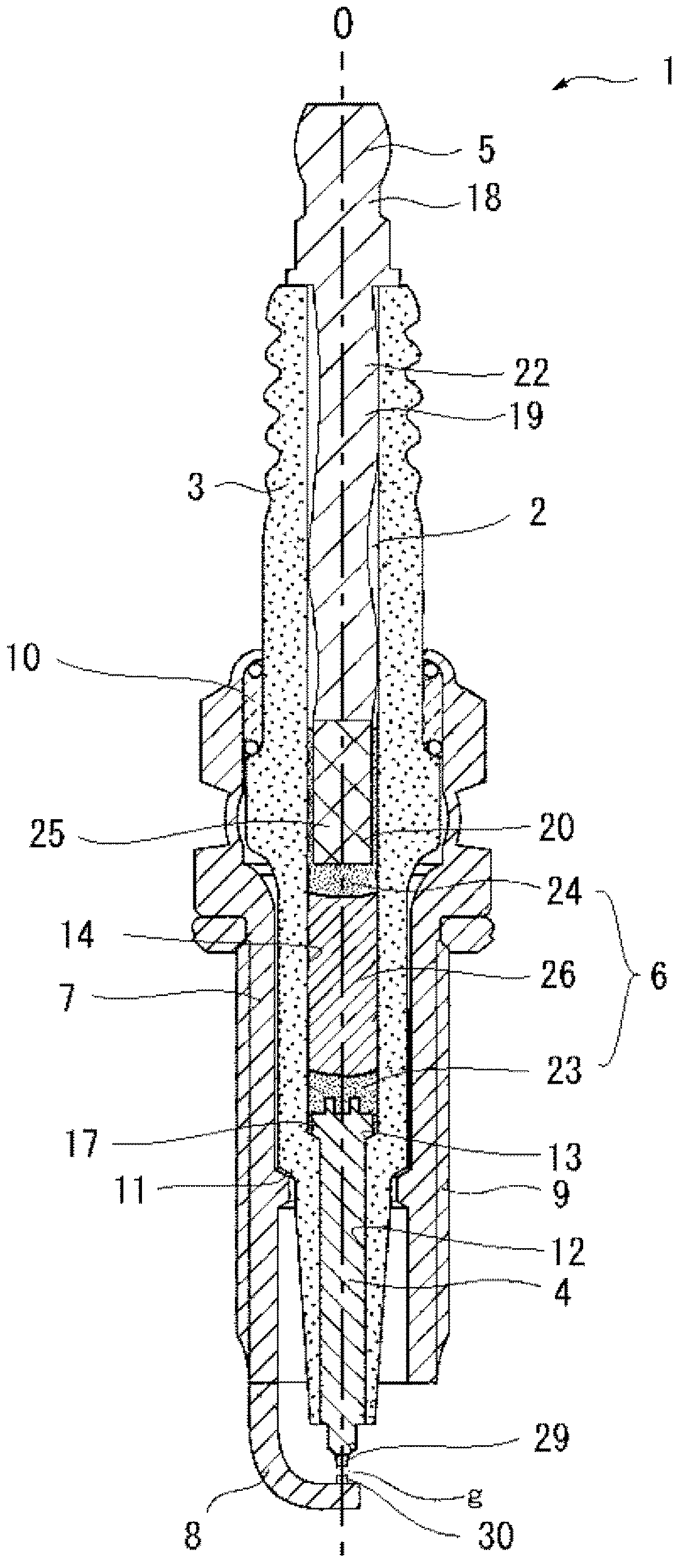

[0109] Made according to the above manufacturing process figure 1 The spark plug shown. In addition, by setting the length in the axial direction of the accommodated portion (the length of the accommodated portion), the inner diameter (diameter of the middle diameter portion) of the shaft hole of the insulator in the front end portion on the center electrode side of the terminal fitting, and the exposure from the above-mentioned third step The length of the axis O direction (exposed length (K)) from the front end of the part to the rear end of the insulator changes, making group B m,y The number and presence of group B m,y The area of the various spark plugs is different.

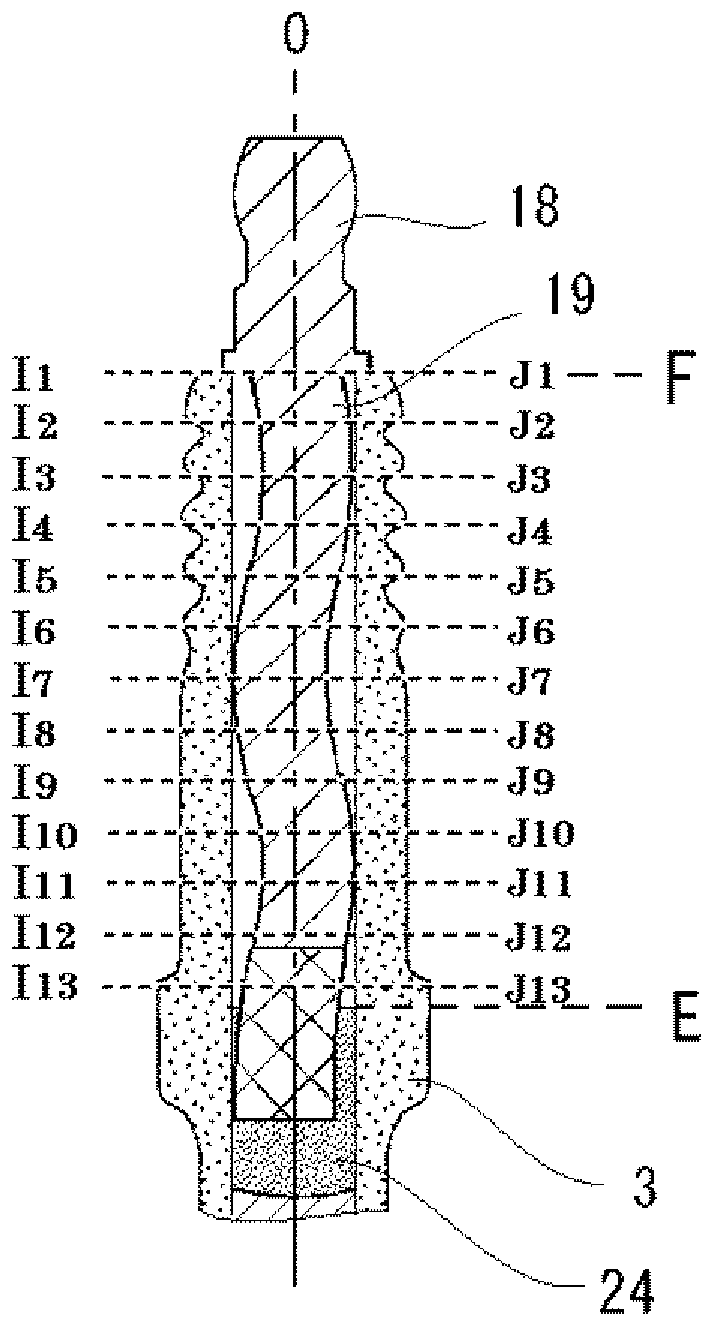

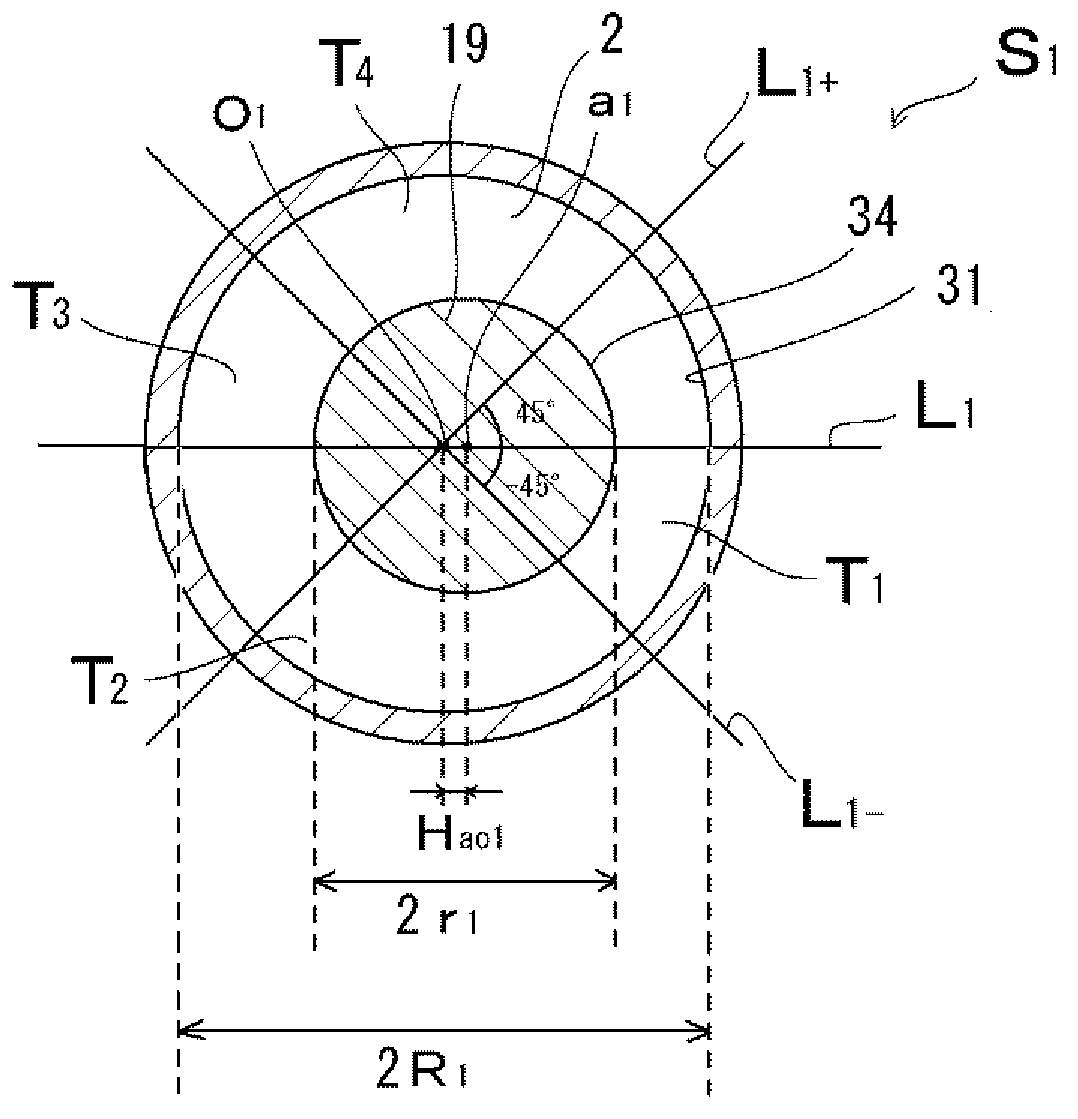

[0110] A micro X-ray CT device (TOSCANER-32250μhd) is used to take cross-sectional images S of each spark plug at 0.5mm intervals from the rear end of the accommodated part toward the front end to the rear end position where the connecting member exists. n , as mentioned above, based on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com