Hydraulic tensioner

A tensioner, hydraulic technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve the problems of high manufacturing cost, difficult setting, and inability to maintain the high-pressure state of the housing 510

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

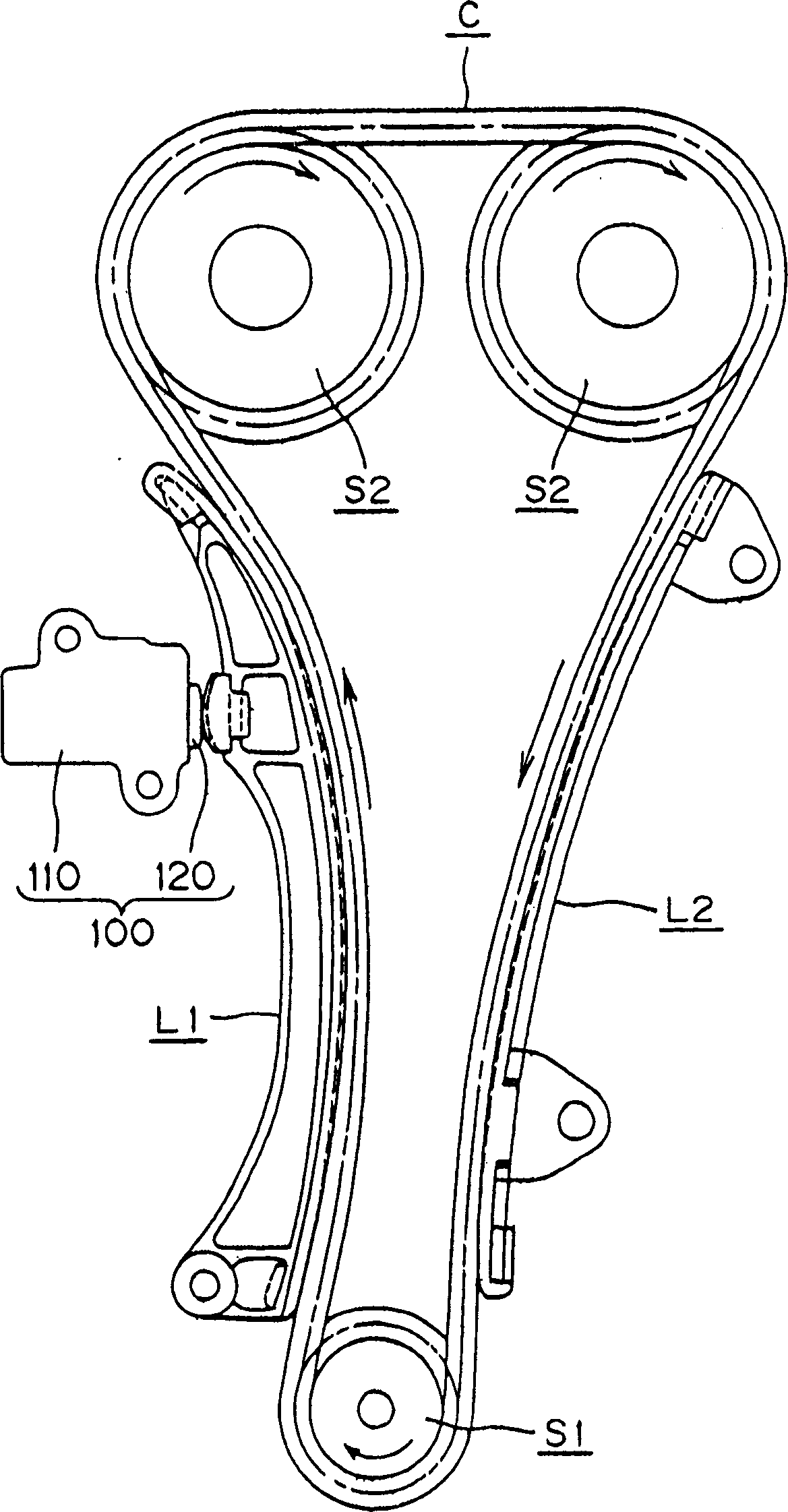

Image

Examples

Embodiment Construction

[0028]The hydraulic tensioner of the present invention is characterized in that it is equipped with a one-way ball valve that prevents the outflow of the pressure oil in the high-pressure oil chamber to extract the air mixed with it, and a ball guide that moves around the one-way ball valve in the state of enclosing the one-way ball valve. The disc-shaped baffle, which is fixed to the ball guide and seals the one-way ball valve in the ball guide, is fixed on the aforementioned ball guide to prevent the pressure oil in the high-pressure oil chamber when the one-way ball valve is in place. The ball seat that flows out of the ball seat, and the ball valve unit that loads the ball valve on the ball seat to the one-way ball valve are loaded with a spring. As long as it is easy to maintain the high pressure state in the housing body, only the negative pressure state is in the housing body. When it is easy to extract the mixed air mixed into the main body of the housing, and the parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com