Multiple point rectifier with brake chopper

A technology of rectifier and braking resistor, applied in the field of drive, to achieve the effect of reducing overhead and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

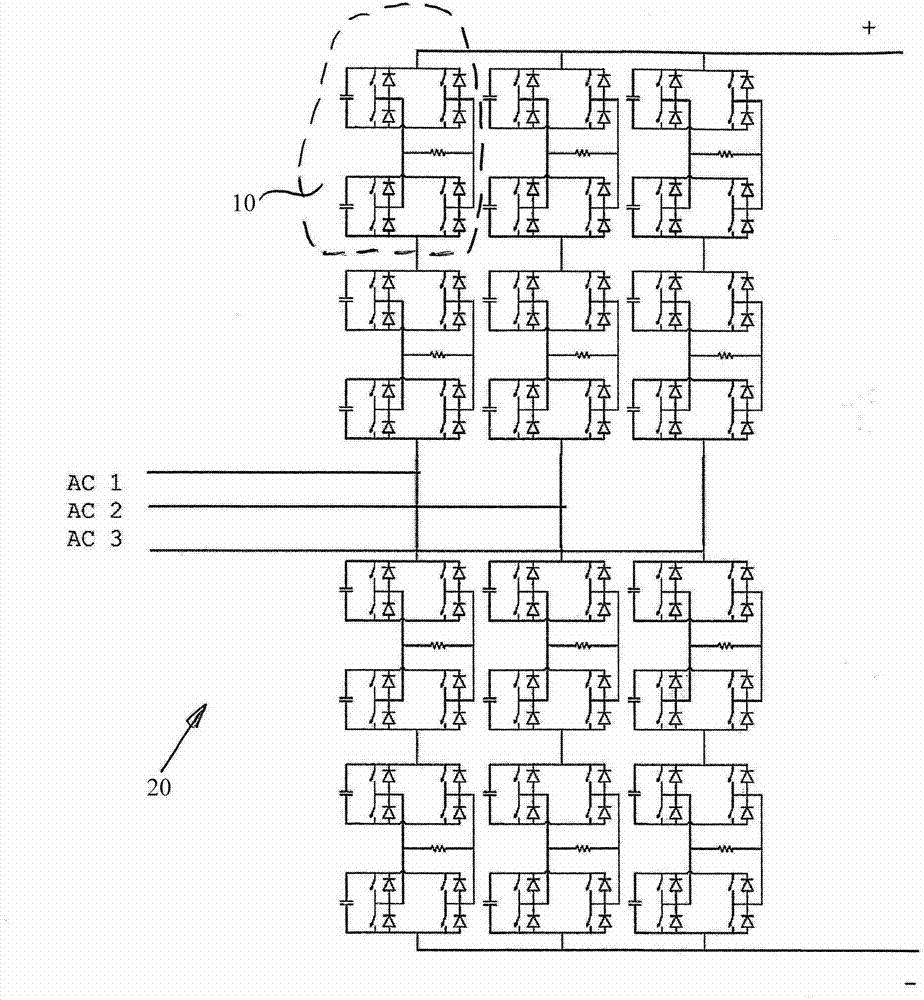

[0024] exist figure 2 A three-phase view of a modular multipoint rectifier 20 is shown in . This type of multipoint converter is also known under the English name "Modular Multilevel Converter" (M2C).

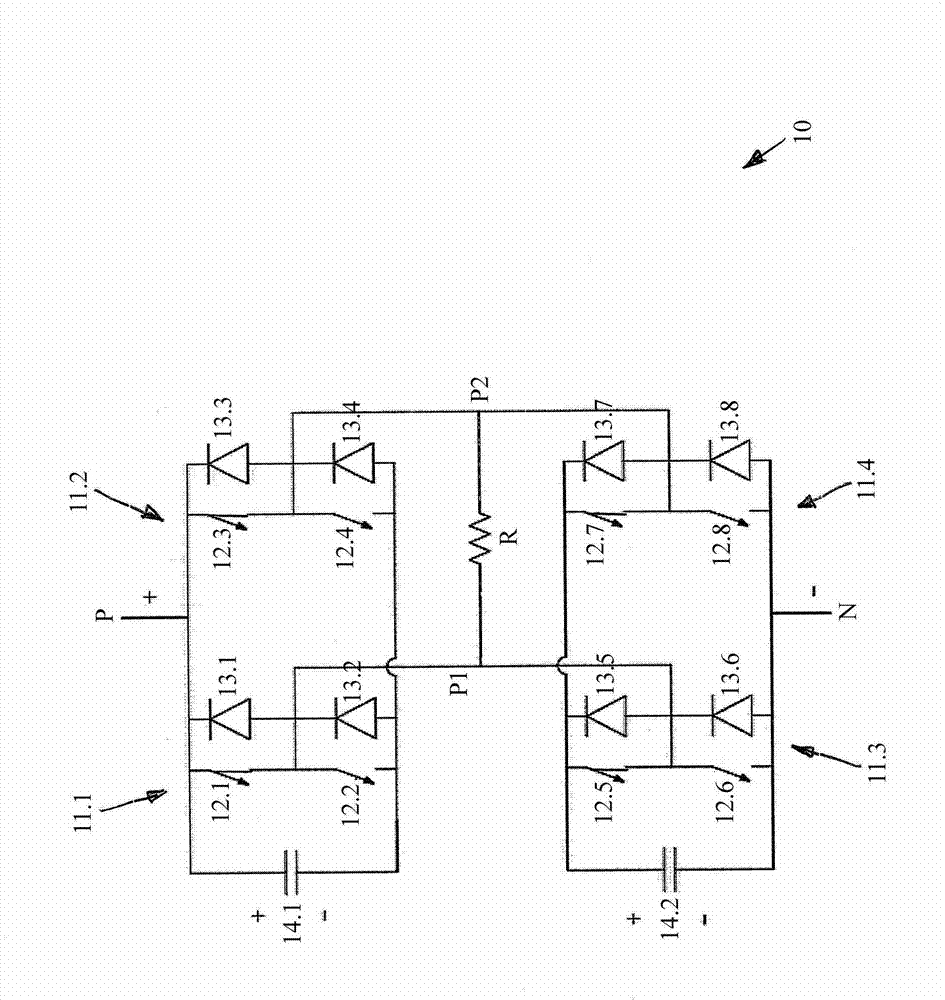

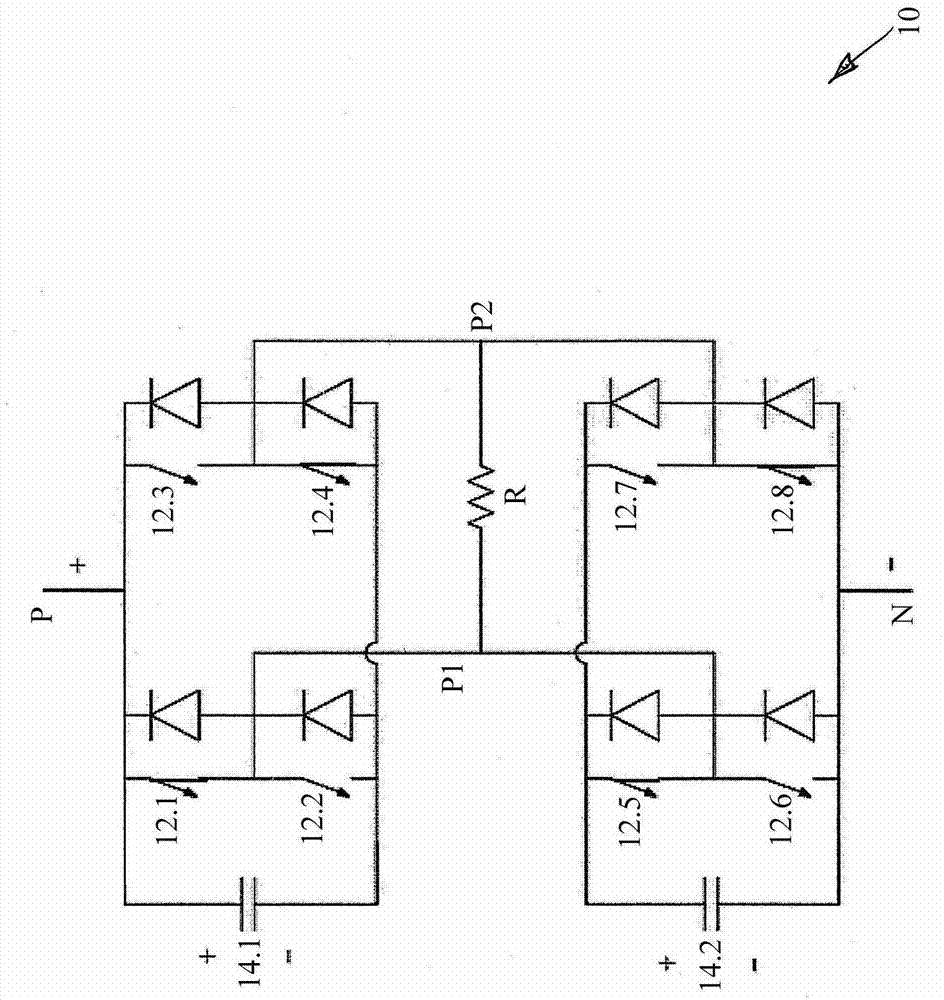

[0025] Each of the three phases of the rectifier 20 is constructed from two parallel circuit configurations. Furthermore, each of the three phases is constituted by a plurality of finisher subsystems 10 , and each phase is constituted by four rectifier subsystems 10 respectively in this embodiment. The individual following references to the rectifier subsystem Figure 1a , 1b explained in more detail.

[0026] The rectifier subsystem 10 includes a parallel circuit configuration. The semiconductor switches of each rectifier subsystem and collectively all rectifier subsystems are used to control the operation of the rectifier 20 . The semiconductor switches of each individual rectifier subsystem 21 are used simultaneously and independently of the other rectifier subsystems...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com