Feeding machine dynamic conveying performance testing platform

A testing platform and conveying performance technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of high intelligence, poor performance and automation, and high price of extruders. , to achieve the effect of compact structure, less labor cost and design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

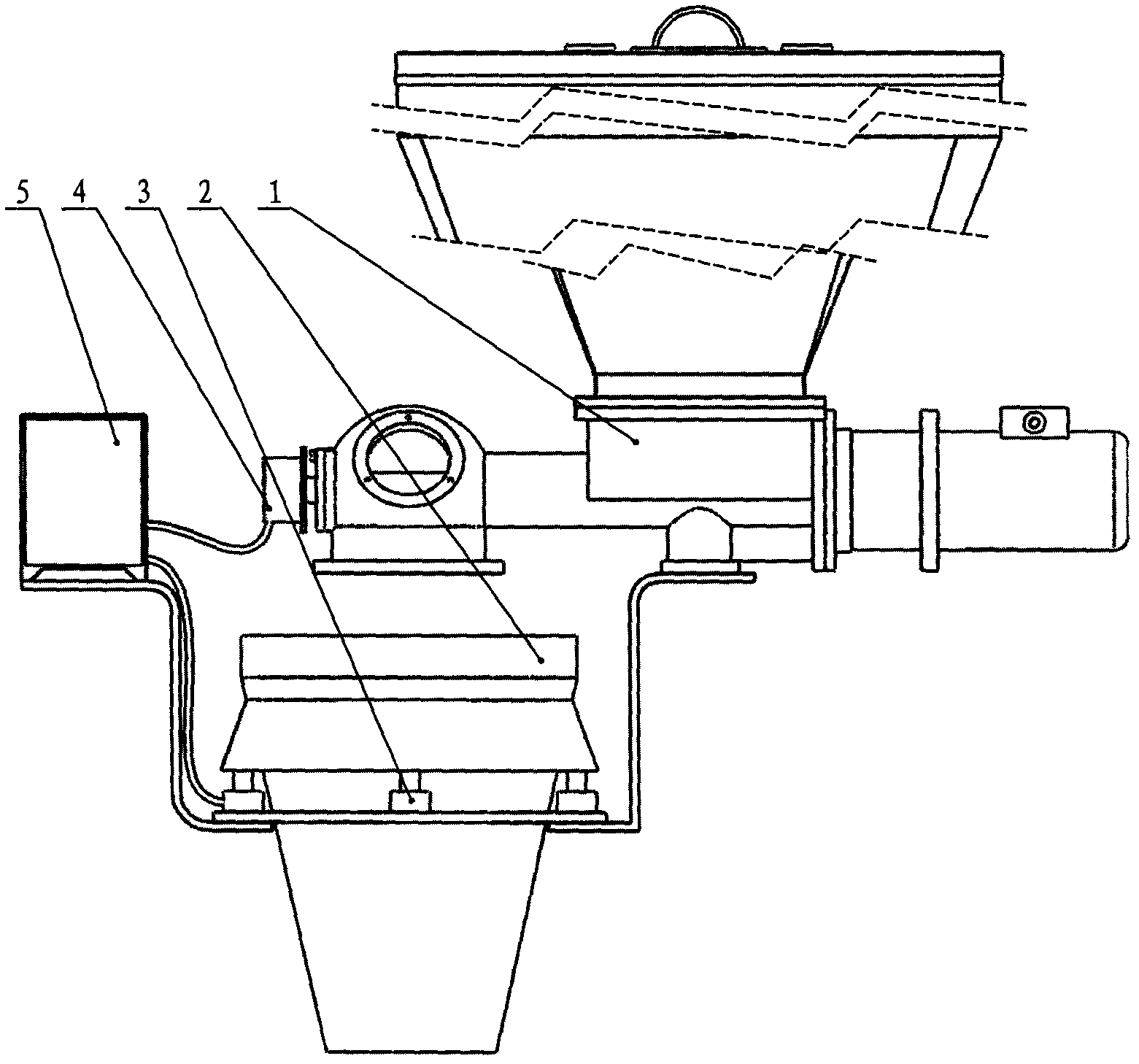

[0014] The weighing barrel (2) is a pair of double-cone rotators, the inner cone is used to store materials, and the outer cone is used to fix and support the barrel. The weighing instrument (3) consists of two Z-shaped frames, a support ring, four support points and signal transmission. Composed of connection lines, the speedometer (4) is installed on the extended end of the feeder (1) conveying screw, connected with the signal recorder (5) with a communication line, and the feeder (1) is supported on the weighing instrument ( 3) on one side of the Z-shaped frame, and the signal recorder (5) is placed on the other side of the weighing instrument (3) on the Z-shaped frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com