Multiple-cavity heat preservation water tank free of water mixing

A heat preservation water tank and multi-cavity technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of increasing the number of water tanks, small heating capacity, and large equipment configuration power, and achieves the effect of reducing the degree of water mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

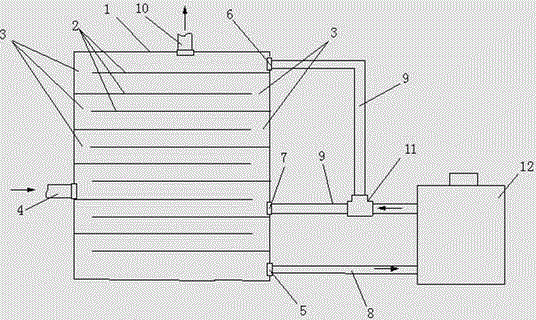

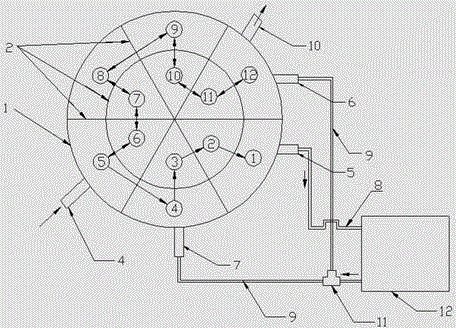

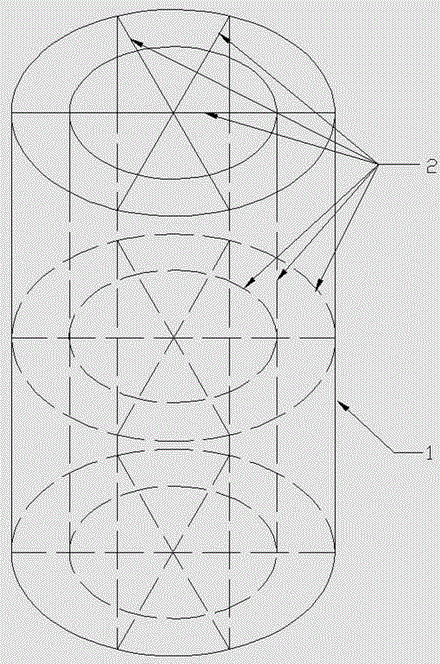

[0039] Embodiment 1: The specific structure and working process of the present invention on the circulating heat pump water heater:

[0040] Such as figure 1 The shown multi-chamber immiscible water insulation water tank includes an insulation box body 1, a cold water supply port 4, a hot water supply port 10 and a temperature probe arranged in the insulation box body 1. The inside of the insulation box body 1 is surrounded by a plurality of insulation The plate 2 is isolated into N cavities from the 1st to the Nth, and N is a natural number not less than 8; the water hole 3 of the first cavity is only connected with the second cavity, and the first cavity is equipped with a water outlet 5. The water outlet 5 is externally connected to the water outlet pipe 8, and the water outlet pipe 8 is connected with the water inlet of the external water pump 12; the water hole 3 of the Nth cavity is only connected with the N-1th cavity, and the Nth cavity is installed with a heat sink. ...

Embodiment 2

[0047]Embodiment 2: The specific structure and working process of the present invention on the heat pump water heater with a built-in heat exchanger in the water tank: the structure and working process of the water tank are basically the same as in Embodiment 1: the heat exchanger (condenser) is installed in the first to the second Between the M cavities, the water supply port is the M+1 cavity, the water outlet on the first cavity is connected to the water inlet of a small power pump, and the N and M cavities are respectively provided with two return ports and corresponding return pipes , 2 return pipes communicate with the water outlet of the water pump through a three-way solenoid valve. When heating, the three-way solenoid valve makes the second water return pipe conduct, the first water return pipe is closed, the water pump runs, the water body circulates between the first to the Mth cavities and heats up, when the outlet water temperature of the host reaches the set tempe...

Embodiment 3

[0048] Embodiment 3: The specific structure and working process of the present invention on the electric water heater: In addition to the cold water replenishment port of the M+1th cavity and the hot water supply port of the Nth main engine of the water tank, the first cavity on the water tank has one outlet Water outlet, the Nth cavity has a water return port, there is a small power water pump between the water outlet and the water return port, and the electric heating tube is between the 1st and Mth cavities. If electric heaters are installed in each cavity from the 1st cavity to the Mth cavity according to the volume ratio of the cavity, the second water return port is not provided, and the water pump does not run during heating, and the water body between the 1st to the Mth cavity When the average temperature reaches the temperature, the water pump will run and pump the heated water into the Nth cavity; the outlet water temperature of the water pump will drop to the set tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com