Mechanical type linear reciprocating synchronizing device

A linear reciprocating and synchronous device technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low heavy load accuracy, small load capacity, and synchronous motion lag, so as to ensure motion synchronization accuracy, improve production efficiency, and synchronize Sexually precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

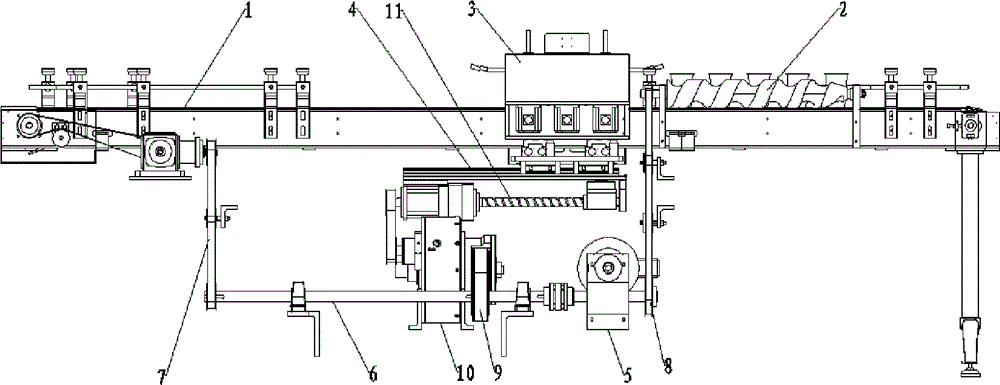

[0012] Embodiment: a kind of mechanical linear reciprocating synchronizing device, comprises conveyor belt 1, separating screw rod 2, manipulator 3 and linear guide rail 4, and separating screw rod 2 can be rotatably positioned on one end of conveyor belt 1, and separating screw rod 2 axially along conveyor belt 1 Placed in the direction of movement, the manipulator 3 can be slidably positioned on the linear guide rail 4, and the linear guide rail 4 is fixed on one side of the width direction of the conveyor belt 1, and is also provided with a motor 5, a main drive shaft 6, a first, a second, a third transmission device 7, 8, 9, the cam mechanism 10, the power output of the motor 5 to the main drive shaft 6, the first, second, and third transmission devices 7, 8, 9 respectively transmit the power of the main drive shaft 6 to the driving roller and the separating screw of the conveyor belt 1 2 and the cam device, the cam mechanism 10 drives the manipulator 3 to slide along the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com