Method and device of whole course uniformly-accelerated mechanical traction high-speed take-off of shipboard aircraft

A technology for mechanical traction and carrier-based aircraft, which is applied in the direction of launch/towing transmission devices, energy-saving operation measures, etc., can solve problems such as unreasonable working principles, ship destruction, and failure to achieve, and achieve low-cost, high-energy utilization. efficiency, less mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

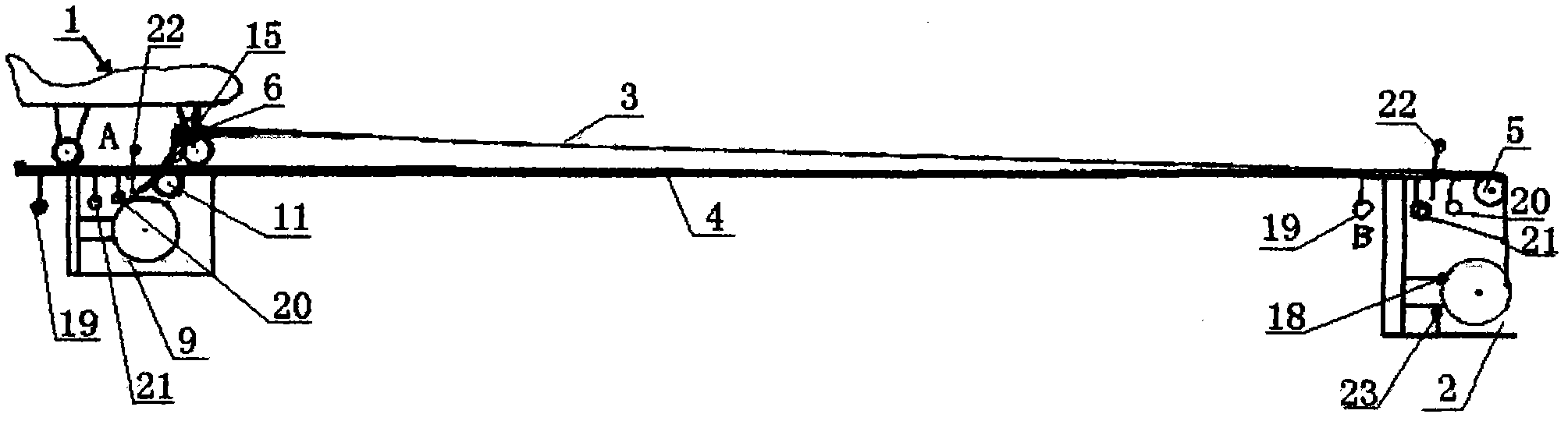

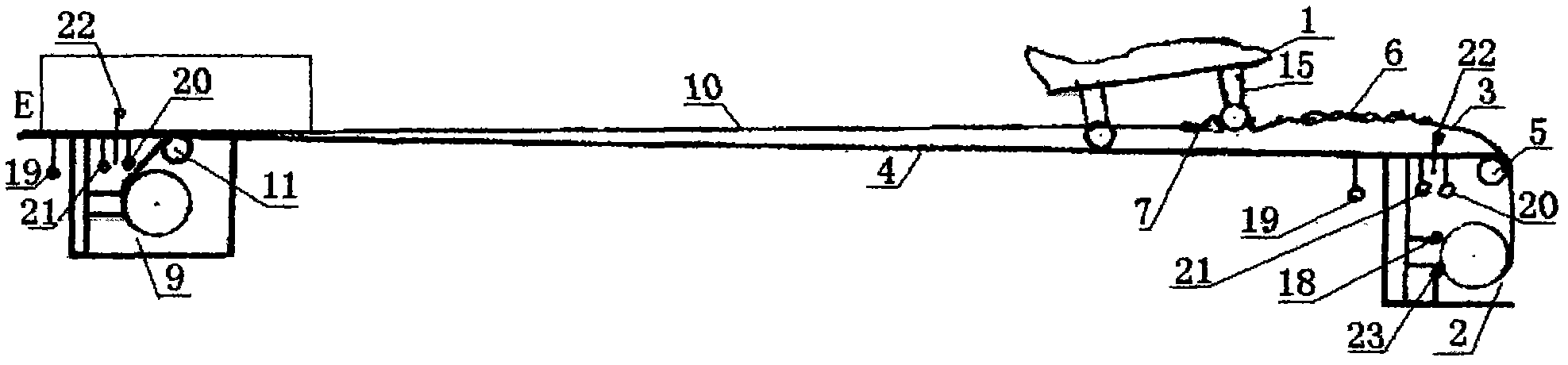

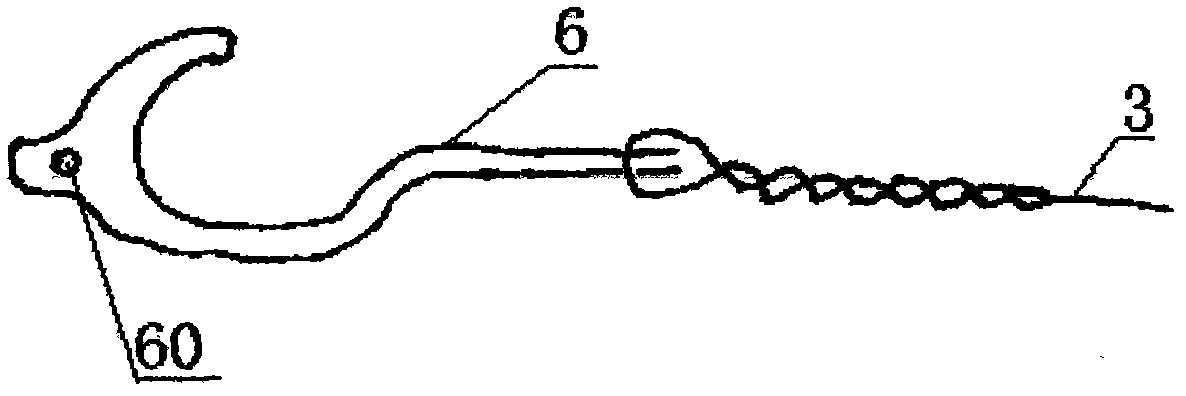

[0024] The carrier-borne aircraft of the present invention uses a high-power winch to tow the carrier-based aircraft to take off at a high-speed take-off method with uniform acceleration throughout the whole process. A high-power modified winch at the bow of the ship pulls the carrier-based aircraft forward to take off, and a low-power general-purpose winch at the stern reversely pulls the hook system or reciprocating vehicle equipped with the carrier-based aircraft back to its position. The modification is to remove the gears of a part of the reduction box and increase the rotating speed of the drum; replace it with a large-diameter drum.

[0025] As shown in the figure, the device used to implement the method of the present invention is to configure a high-power winch 2 under the deck 4, and the winch pulls the hook system or the reciprocating vehicle through the wire rope, and the hook system or the reciprocating vehicle drives the carrier aircraft 1 again.

[0026] Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com