Synchronous width modulation guide rail system of crest welder

A technology of guide rail system and wave soldering machine, which is applied in the direction of metal processing, electrical component assembly and printed circuit, etc., can solve the problems of synchronous transmission action damage, safety accident equipment, accidents, etc., achieve reasonable structural design, improve product quality, and improve Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

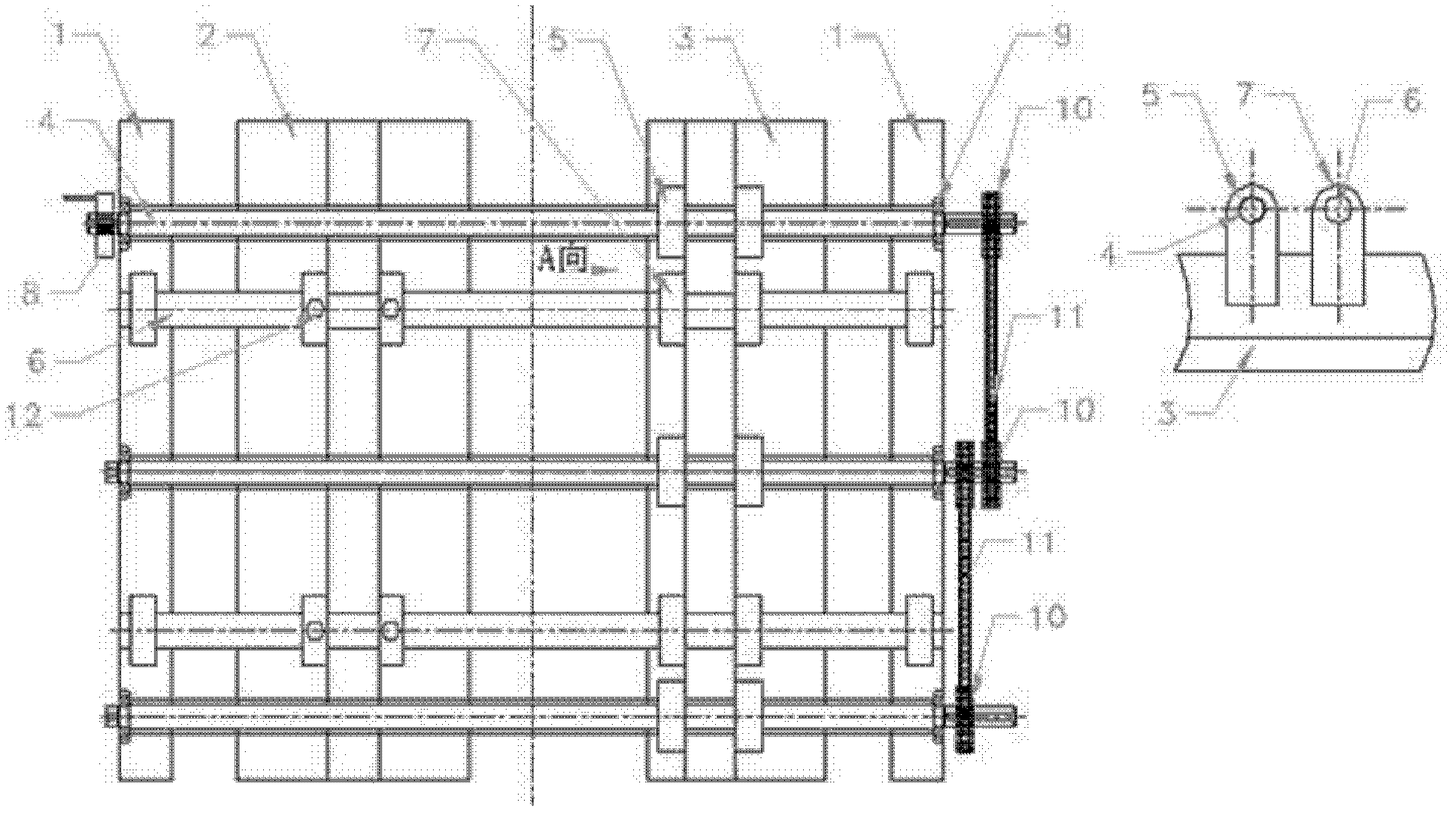

[0009] As shown in Figure 1, the present invention is a synchronous width-adjusting guide rail system for a wave soldering machine, including a bracket 1, a fixed guide rail 2, a movable guide rail 3, a width-adjusting screw shaft 4, a width-adjusting nut 5, a guide shaft 6, and a guide sleeve 7. Hand wheel 8, bearing 9, transmission gear 10, transmission chain 11 and top wire 12, fixed guide rail 2 hangs on guide shaft 6 through guide sleeve 7, and is fixed with top wire 12 to prevent it from moving. Guide shaft 6 Fixed on the bracket 1, the movable guide rail 3 is hung on the guide shaft 6 through the guide sleeve 7, the width-adjusting nut 5 is welded on the movable guide rail 3, and forms a threaded fit with the width-adjusting threaded shaft 4, when the threaded shaft 4 rotates, The movable guide rail 3 is hung on the two guide shafts 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com