Heavy dirty oil storage tank oil-water separation detection discharging method

A technology for oil-water separation and heavy dirty oil, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., to achieve the effect of improving labor efficiency, reducing labor intensity, and obvious separation cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

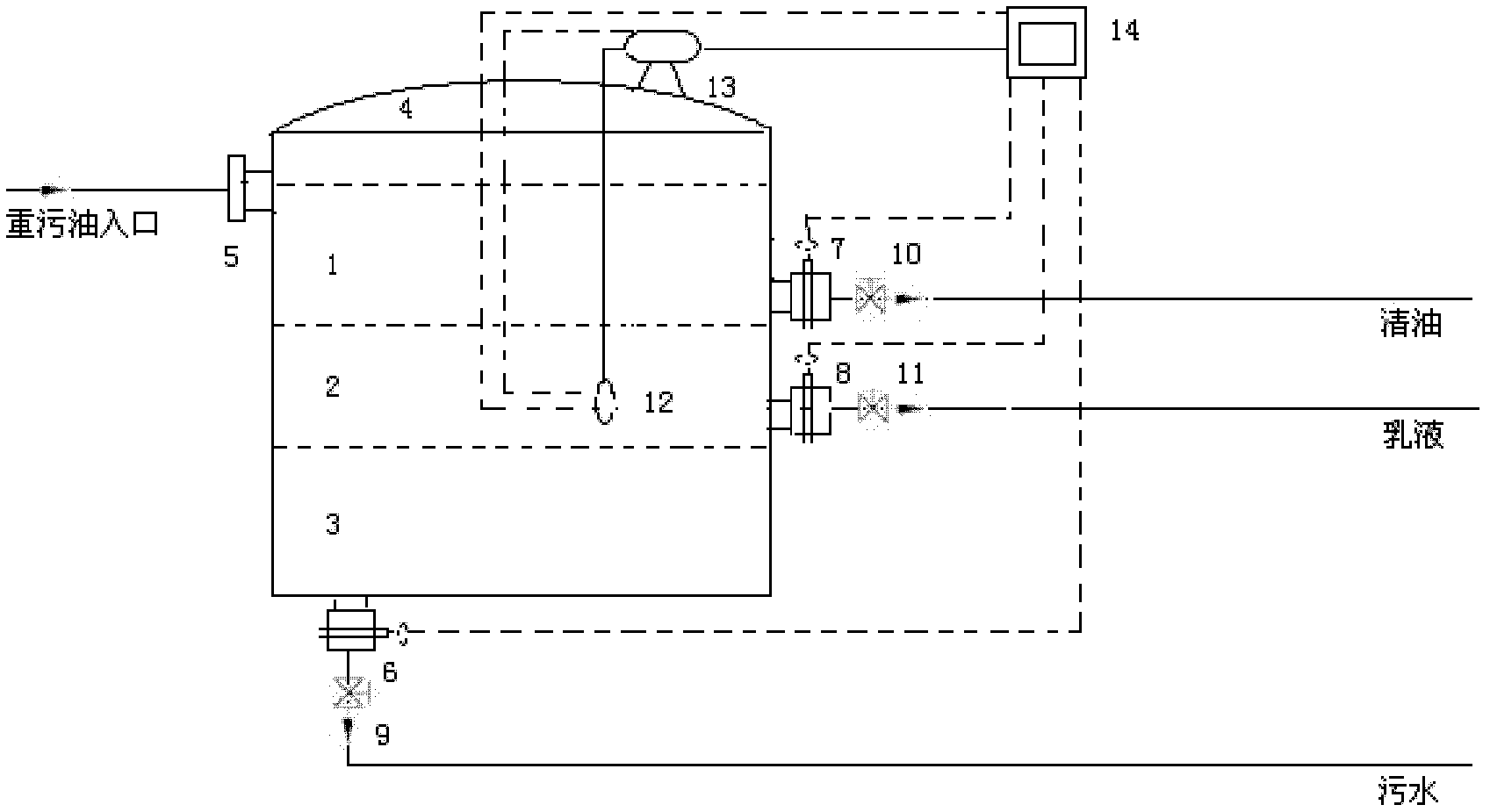

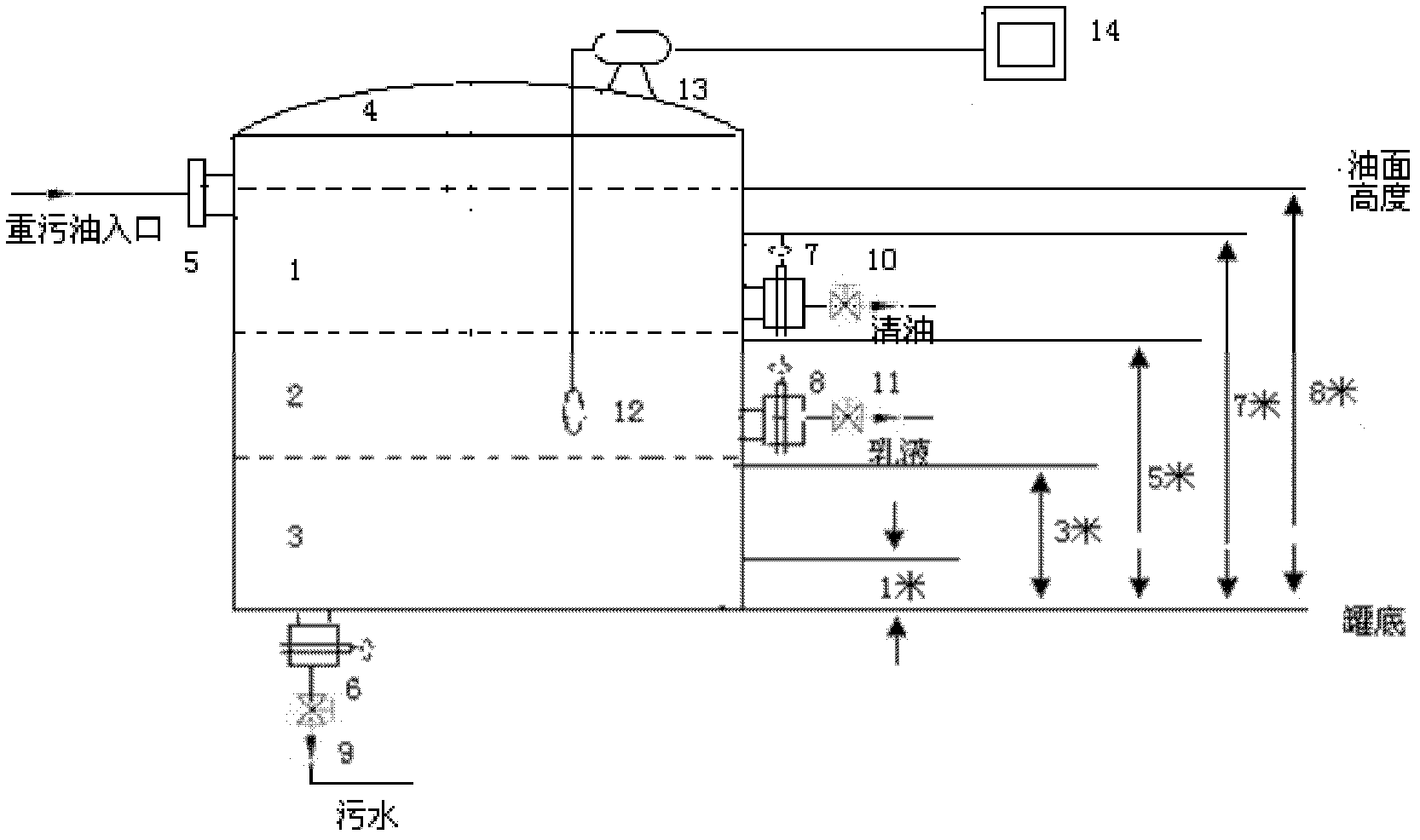

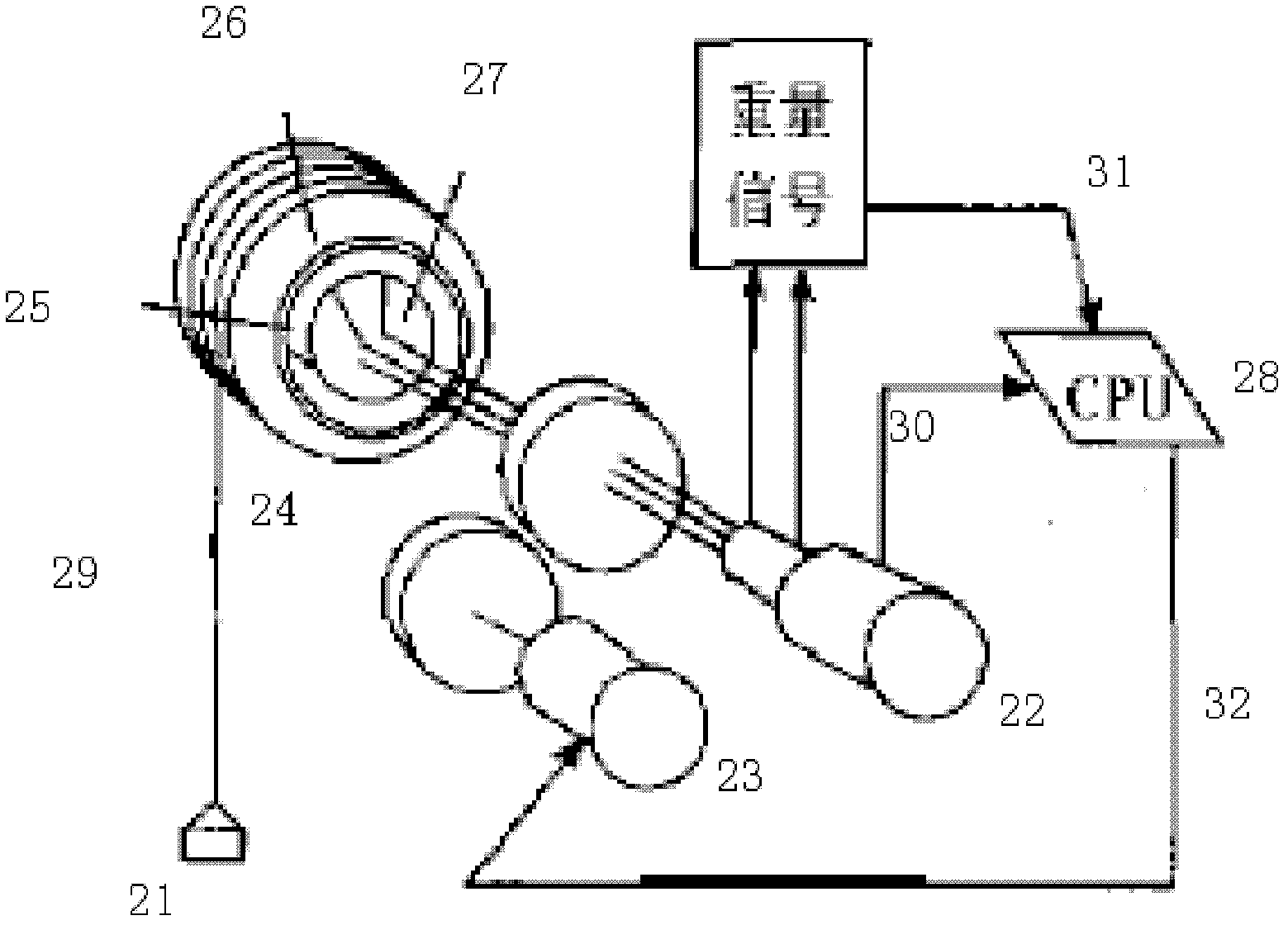

[0021] 1) For the detection of remote control of oil-water separation, a servo motor is installed on the upper part of the heavy dirty oil settling tank, and one end of the servo motor is connected with an electromagnetic sensor and a float for measuring the liquid level, and the sampling signal of the electromagnetic sensor and the float is connected to a microprocessor and a computer Control System;

[0022] The servo motor and the float are connected by a thin steel wire. When the servo motor is working, the gravity of the float acting on the thin steel wire will generate a torque on the magnet of the outer drum—magnetic coupling torque, which will cause a change in the magnetic flux; the magnetic flux between the outer drum components The change causes the output voltage signal of the electromagnetic sensor (Hall element) installed on the inner magnet to change; its voltage value is compared with the reference voltage stored in the microprocessor CPU; when the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com