Systems and methods for selective tungsten deposition in vias

A deposition cycle and metal deposition technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of tungsten grain growth limitation, limitation of tungsten filling amount, damage to perforation resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following description is merely exemplary in nature and not limiting of the invention, its application or uses. For clarity of illustration, the same reference numerals will be used in the drawings to refer to similar elements. In this article, statements such as "at least one of A, B, and C" should be interpreted as the meaning of logic (A or B or C) using a non-exclusive logical "or". It should be understood that steps of a method may be executed in different order without altering the principles of the present invention.

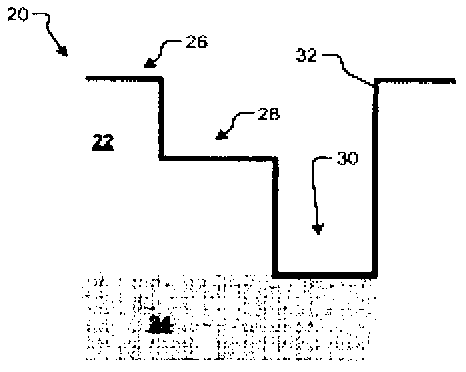

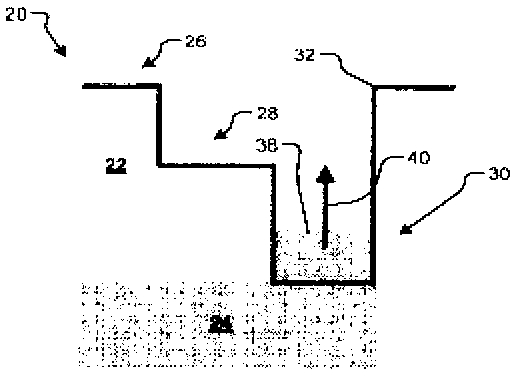

[0034] The present invention utilizes metal selective growth, such as but not limited to chemical vapor deposition tungsten (CVD-W: chemical vapor deposition tungsten), to at least partially fill the vias using a bottom-up approach. This selective growth is followed by non-selective growth in the trenches and / or fields.

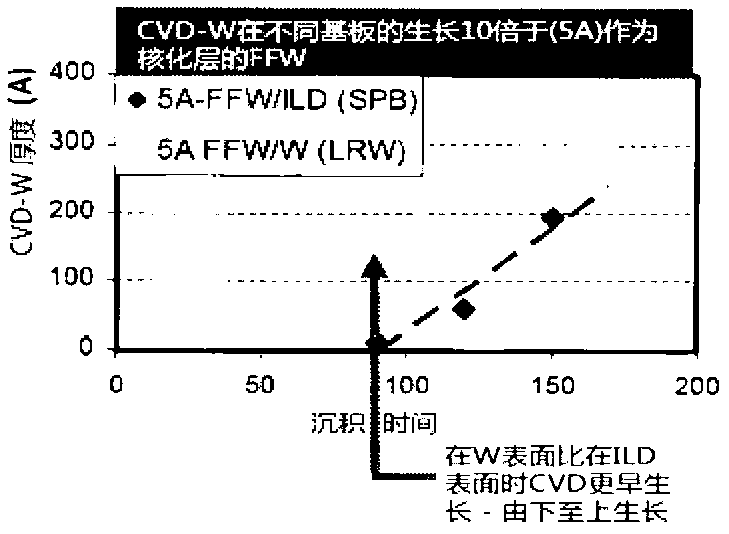

[0035] Metal selective growth such as but not limited to CVD-W, compared with interlayer dielectric (ILD: interlayer diele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com