Flexible watertight roof coatings

A coating, coating technology for the manufacture of roof coatings, polymer blends, capable of solving problems not described with crack bridging qualities or permanently flexible roof coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

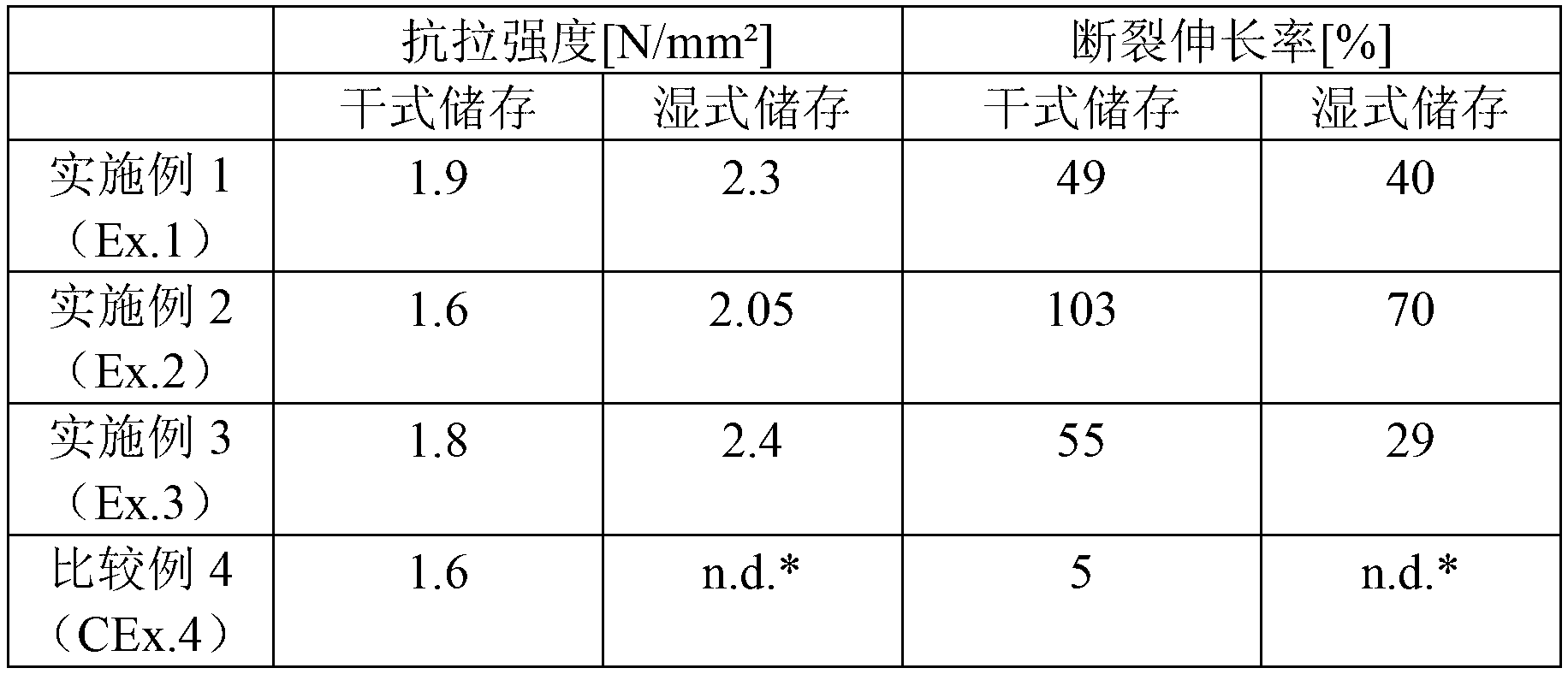

Examples

Embodiment 1

[0062] Embodiment 1 (Ex.1):

[0063] For preparing the coating composition, the ingredients of the dry formulation shown below were placed in a Toni mixer (factory laboratory mixer) and mixed homogeneously on stage 1 for 15 minutes. An aqueous coating composition was prepared from the resulting dry mixture in a similar manner to EN 196-1, using 32% by weight of water, based on the total weight of the dry formulation.

[0064] Dry formula:

[0065] 10% by weight Portland cement,

[0066] 30% by weight quartz sand (diameter: 0.063mm to 0.3mm),

[0067] 13.4% by weight calcium carbonate,

[0068]0.5% by weight of highly dispersible silica (Wacker HDK H15),

[0069] 0.5% by weight defoamer (polysiloxane (silicone) defoamer),

[0070] 1.5% by weight bentonite,

[0071] 44.1% by weight of VINNAPAS LL4040N (vinyl acetate-ethylene copolymer stabilized with polyvinyl alcohol and cationic protective colloid).

[0072] The aqueous coating composition was coated onto a Teflon formw...

Embodiment 2

[0075] Example 2 (Ex.2):

[0076] Similar to Example 1, except that the following dry formula and the following amounts of water were used to prepare the coating composition:

[0077] Dry formula:

[0078] 20% by weight Portland cement,

[0079] 35.9% by weight quartz sand,

[0080] 2% by weight titanium dioxide,

[0081] 0.6% by weight accelerator (calcium formate),

[0082] 1.5% by weight bentonite,

[0083] 40% by weight of VINNAPAS 7055N (vinyl acetate-ethylene-vinyl ester terpolymer stabilized with polyvinyl alcohol).

[0084] Based on the total weight of the dry formulation, 30% by weight of water was used.

Embodiment 3

[0085] Embodiment 3 (Ex.3):

[0086] Similar to Example 1, except that the following dry formula and the following amounts of water were used to prepare the coating composition:

[0087] Dry formula:

[0088] 13% by weight Portland cement,

[0089] 5% by weight aluminate cement,

[0090] 32% by weight quartz sand,

[0091] 5% by weight lightweight filler,

[0092] 13.4% by weight calcium carbonate,

[0093] 0.1% by weight blocker (sodium tartrate),

[0094] 0.5% by weight of highly dispersible silica (Wacker HDK H15),

[0095] 0.3% by weight polyacrylonitrile fibers,

[0096] 0.7% by weight thickener (acrylate thickener),

[0097] 30% by weight of VINNAPAS 5044N (vinyl acetate-ethylene copolymer stabilized with polyvinyl alcohol).

[0098] Based on the total weight of the dry formulation, 35% by weight of water was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| apparent density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com