Coating agents for producing permanently flexible coatings

A technology of composition and coating, applied in the direction of lime coating, etc., can solve the problems that the coating is prone to cracks, damage, and cannot be fully achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

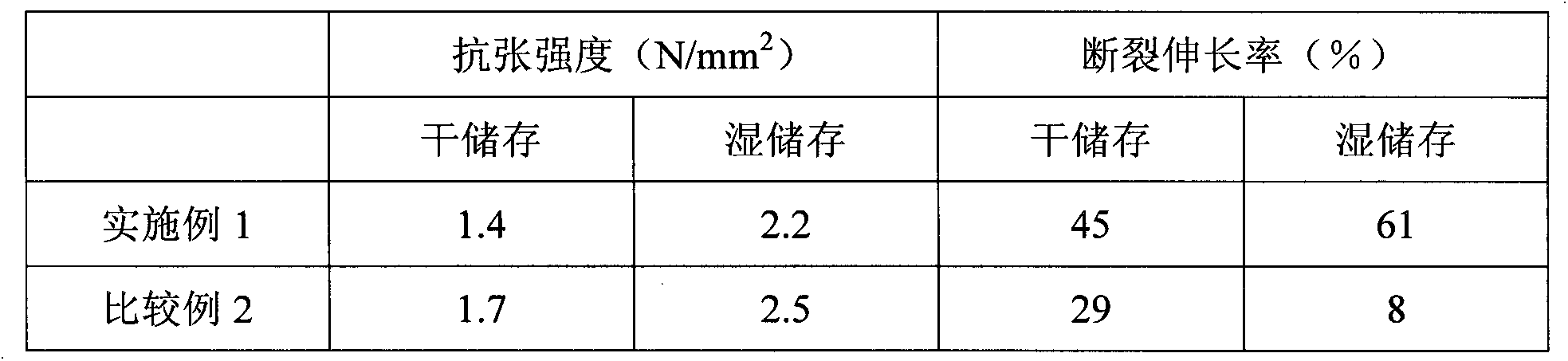

Examples

Embodiment 1

[0058] Coating compositions were prepared by adding the ingredients of the following formulations to a Toni mixer (commercial test mixer) under agitation in the following order: first the slaked lime, then the filler, dispersion powder and finally the rest of the additives. After this, mix well on setting 1 for 15 minutes. From the resulting dry mix, aqueous coating compositions were prepared using the stated amounts of water in the manner described in EN 196-1.

[0059] The aqueous coating composition was applied at a wet film thickness of 2 mm on a Teflon formwork assembly (bottom area: 30 x 15 cm). Smooth the wet film with a trowel. After 24 hours of storage under standard conditions according to DIN 50014, the film was cured and after removal of the Teflon formwork components it was placed under the following storage conditions:

[0060] - store one film under standard conditions (23°C / 50% relative humidity) for 28 days (dry storage),

[0061] - Following the dry storag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com