Sodium-sulfur battery

A sodium-sulfur battery and sodium storage tube technology, which is applied in the field of energy storage, can solve the problems of limiting the flow rate of liquid sodium, the length deviation of ceramic electrolyte tubes, and high dimensional accuracy requirements, so as to reduce the dimensional accuracy requirements, reduce the probability of rupture, and reduce the The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

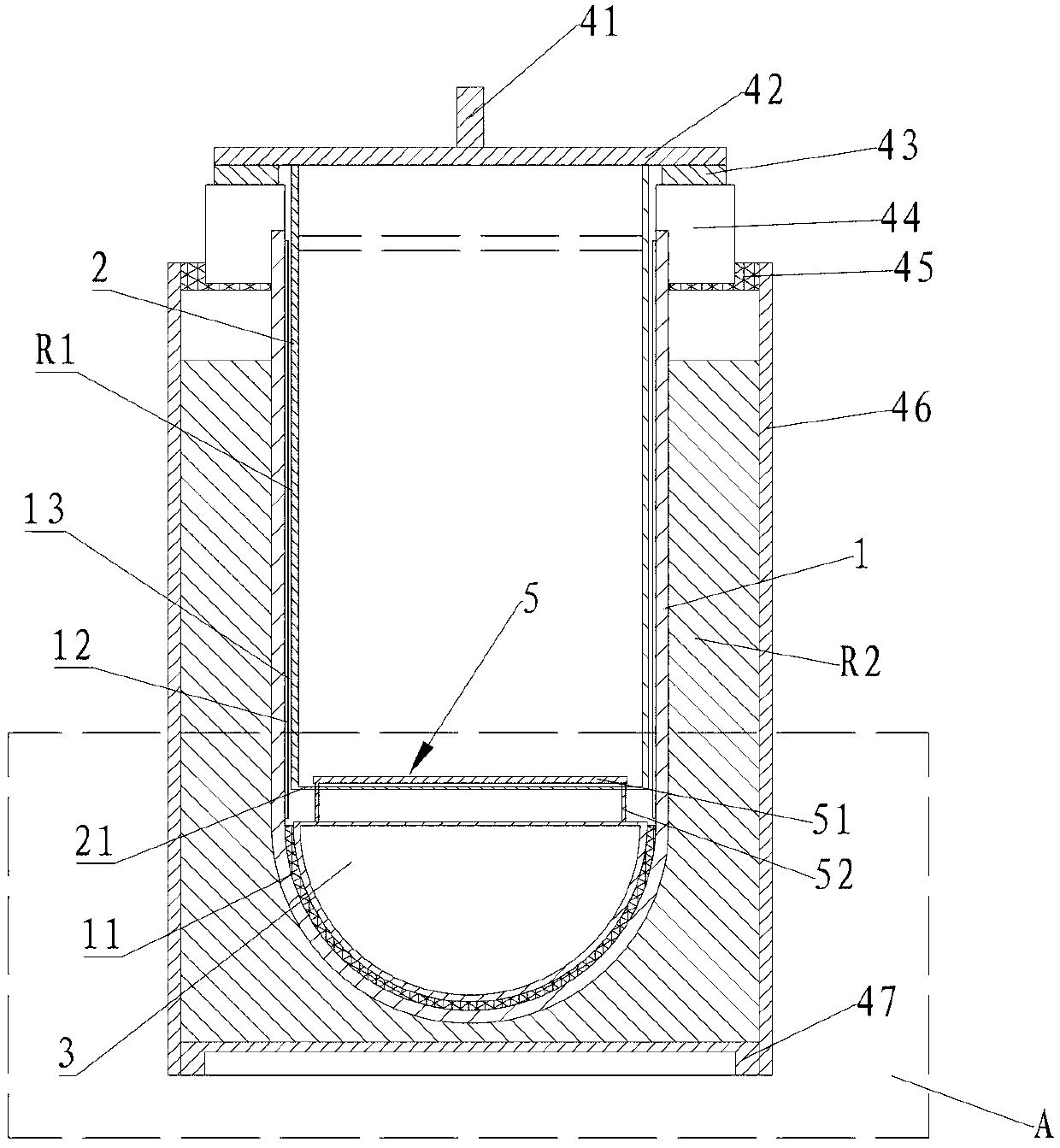

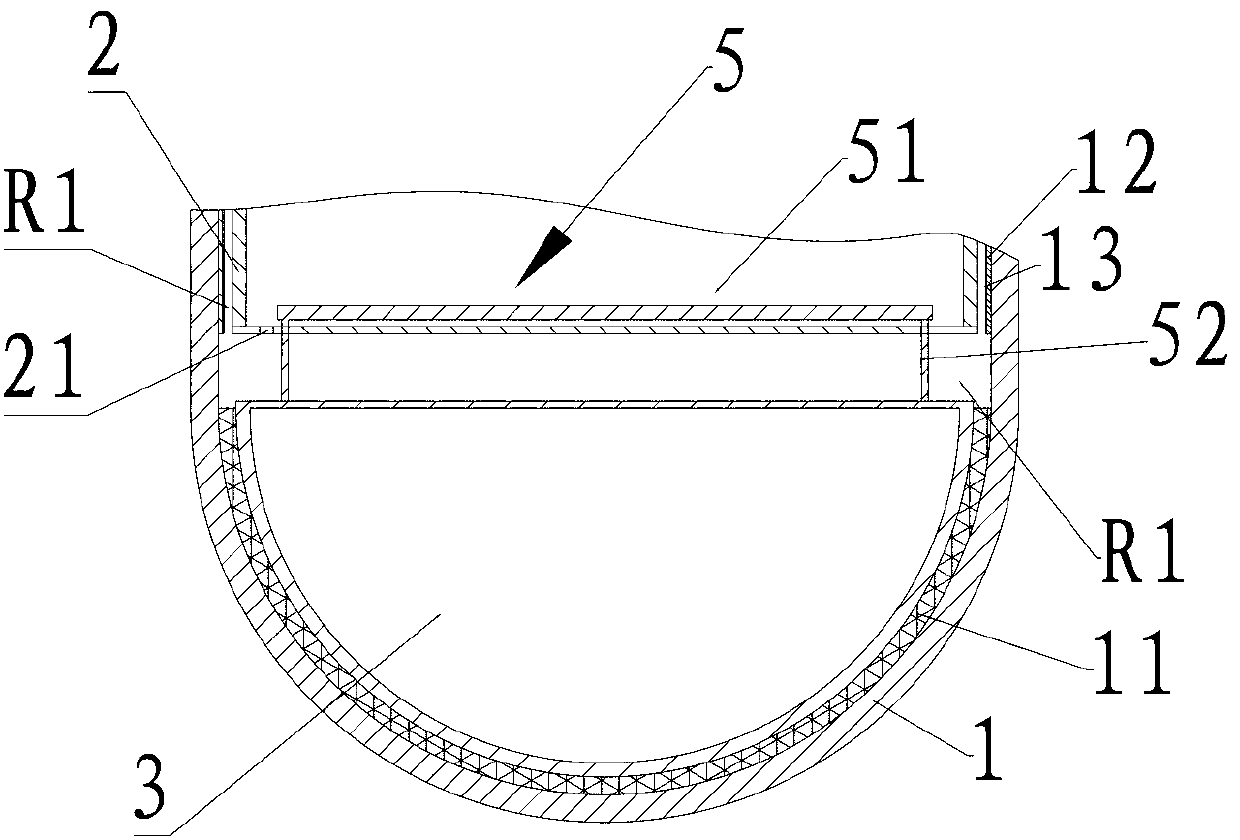

[0018] A sodium-sulfur battery of the present invention comprises a ceramic electrolyte tube 1 and a sodium storage tube 2 sleeved in the ceramic electrolyte tube 1, an annular gap is formed between the sodium storage tube 2 and the ceramic electrolyte tube 1, and the gap is filled with sodium-sulfur The cathode chamber R1 of the battery.

[0019] The bottom surface of the sodium storage tube 2 is flat, and the bottom surface of the sodium storage tube 2 is provided with at least one through hole 21, and the sodium storage tube hemisphere 3 is provided directly below the sodium storage tube 2, and the sodium storage tube hemisphere 3 is connected with the sodium storage tube. There is a gap between the bottom surfaces of the tubes 2, so that the liquid sodium in the sodium storage tube 2 can flow out along the through hole 21 positioned at the bottom surface of the sodium storage tube 2. A fiber buffer layer 11 is provided between the bottom surface of the hemisphere 3 of the ...

Embodiment 2

[0022] see figure 1 , Embodiment 2 is a further improvement on the basis of Embodiment 1. The improvement is that a metal fiber cloth 12 that is close to the inner wall of the ceramic electrolyte tube 1 is provided in the cathode chamber R1, and a metal fiber cloth 12 that is close to the metal fiber cloth 12 Metal foil 13 on the surface. The metal fiber cloth 12 is wet to liquid sodium. Metal foil 13 still has good elasticity at 300°C. The metal fiber cloth 12 has good wettability with liquid sodium at 300°C. At the same time, because the inner wall of the ceramic electrolyte tube 1 has a certain roundness tolerance and the surface is uneven, the metal fiber cloth 12 can make up for the inner wall of the ceramic electrolyte tube 1. roundness tolerance and surface unevenness. Coupled with the elastic effect of the metal foil 13, a number of capillary gaps (not shown in the figure) parallel to the axial direction of the ceramic electrolyte tube 1 are formed between the metal...

Embodiment 3

[0025]Embodiment 3 is a further improvement on embodiment 1 or 2. In embodiment 3, a guide mechanism 5 is provided between the sodium storage tube hemisphere 3 and the sodium storage tube 2, and the guide mechanism 5 includes a piece located in the sodium storage tube 2 Dividing plate 51, and the guiding part 52 that connects dividing plate 51 and sodium storage tube hemisphere 3 top surfaces, in the present embodiment, guiding part 52 is the annulus that connects dividing plate 51 and sodium storage tube hemisphere 3 top surfaces, When the sodium storage tube 2 expands, the ring accurately locates the trajectory of the bottom surface of the sodium storage tube 2, so that the bottom surface of the sodium storage tube 2 drops vertically along the ring, and finally the top surface of the sodium storage tube hemisphere 3 moves the sodium storage tube The through hole 21 on the bottom surface of 2 is closed, and liquid sodium no longer flows out from the through hole 21 on the bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com