Mini-type mobile machinery shop air-conditioner

A kind of engineering vehicle, small-scale technology, applied in the direction of air conditioning system, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of high condensed water content, low heat transfer rate of evaporator, large volume of air conditioner, etc. Achieve high heat transfer rate, reduce air volume loss, and small wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiment is described in further detail below in conjunction with accompanying drawing:

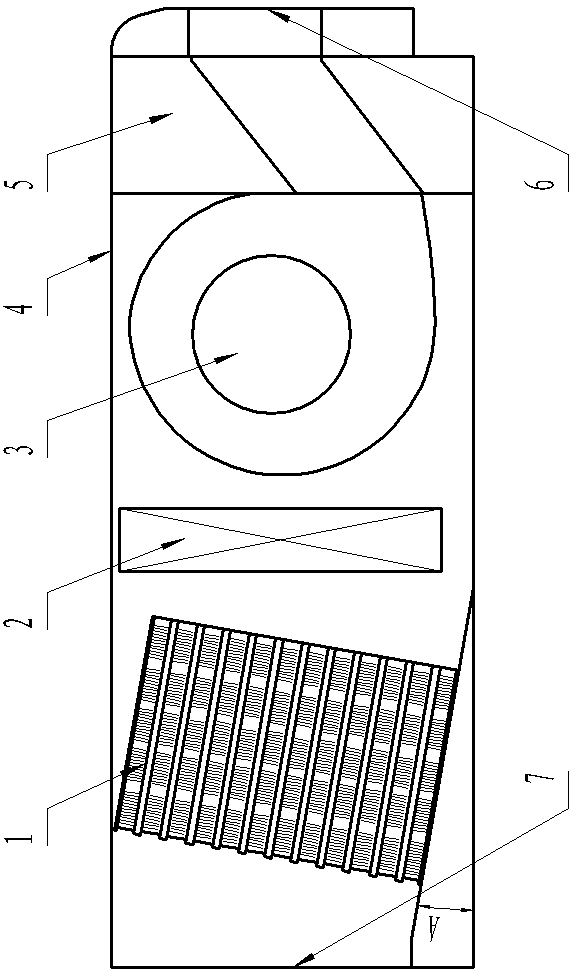

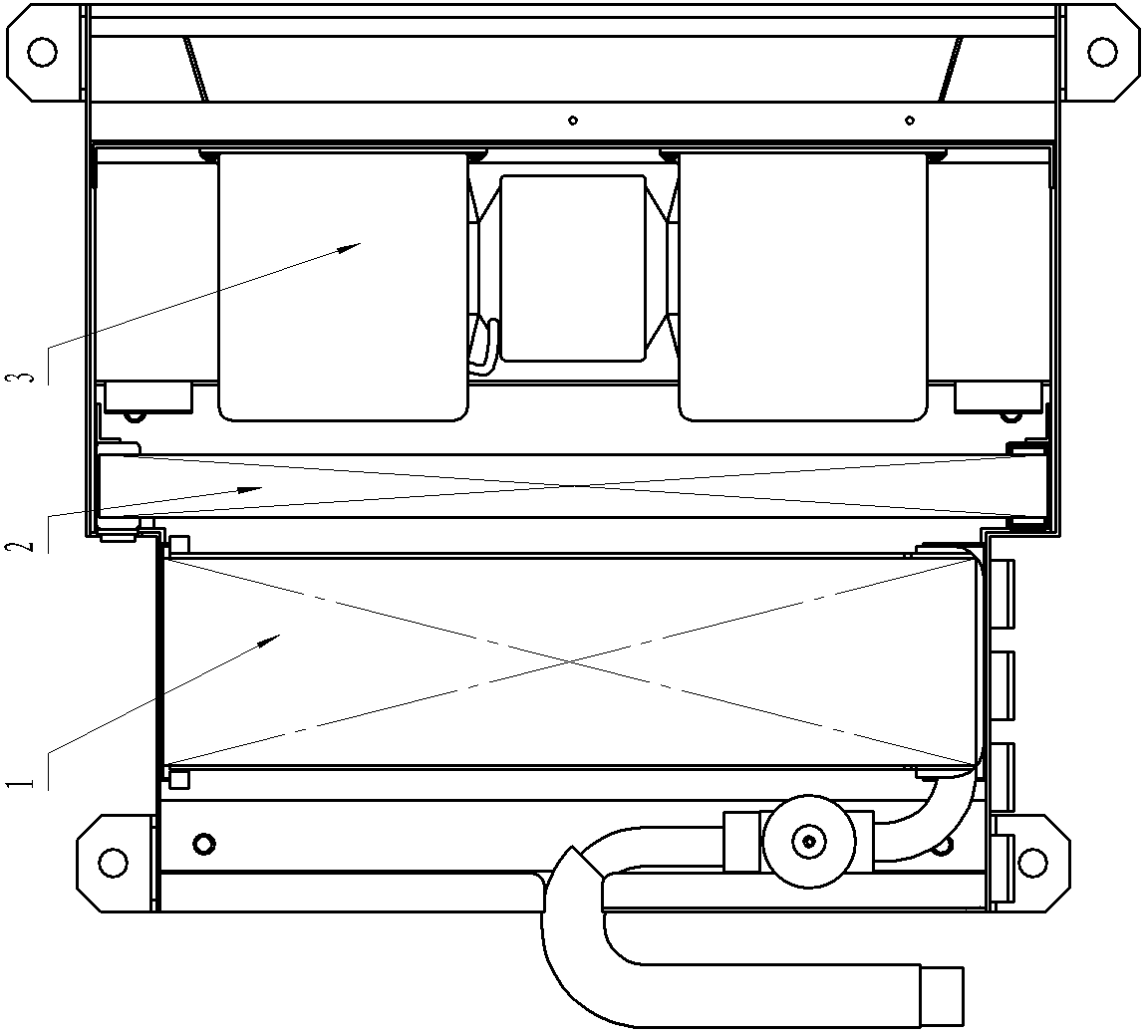

[0014] figure 1 and figure 2 The air conditioner for small engineering vehicles shown includes a stacked evaporator 1, a heater 2 and a blower 3 installed in a casing 4; from the air inlet 7 at one end of the casing 4 to the air outlet 6 at the other end, the casing 4. The inner cavity forms an air flow channel. The evaporator 1 is horizontally arranged on the air flow channel at the end of the housing 4 close to the air inlet 7, and the angle A between the main flow plate and the horizontal plane is 15 degrees. At this time, the evaporator 1 heat sink The condensed water content can be relatively small, and the heat exchange efficiency of the evaporator 1 is improved; the heater 2 and the blower 3 are arranged on the air flow channel behind the evaporator 1; between the air outlet side of the blower 3 and the air outlet 6 of the air flow channel There is an equalizing air cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com