Method for washing crude terephthalic acid filter cake

A kind of technology of crude terephthalic acid and washing method, applied in the field of washing of crude terephthalic acid filter cake, and can solve the problem of high paraxylene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

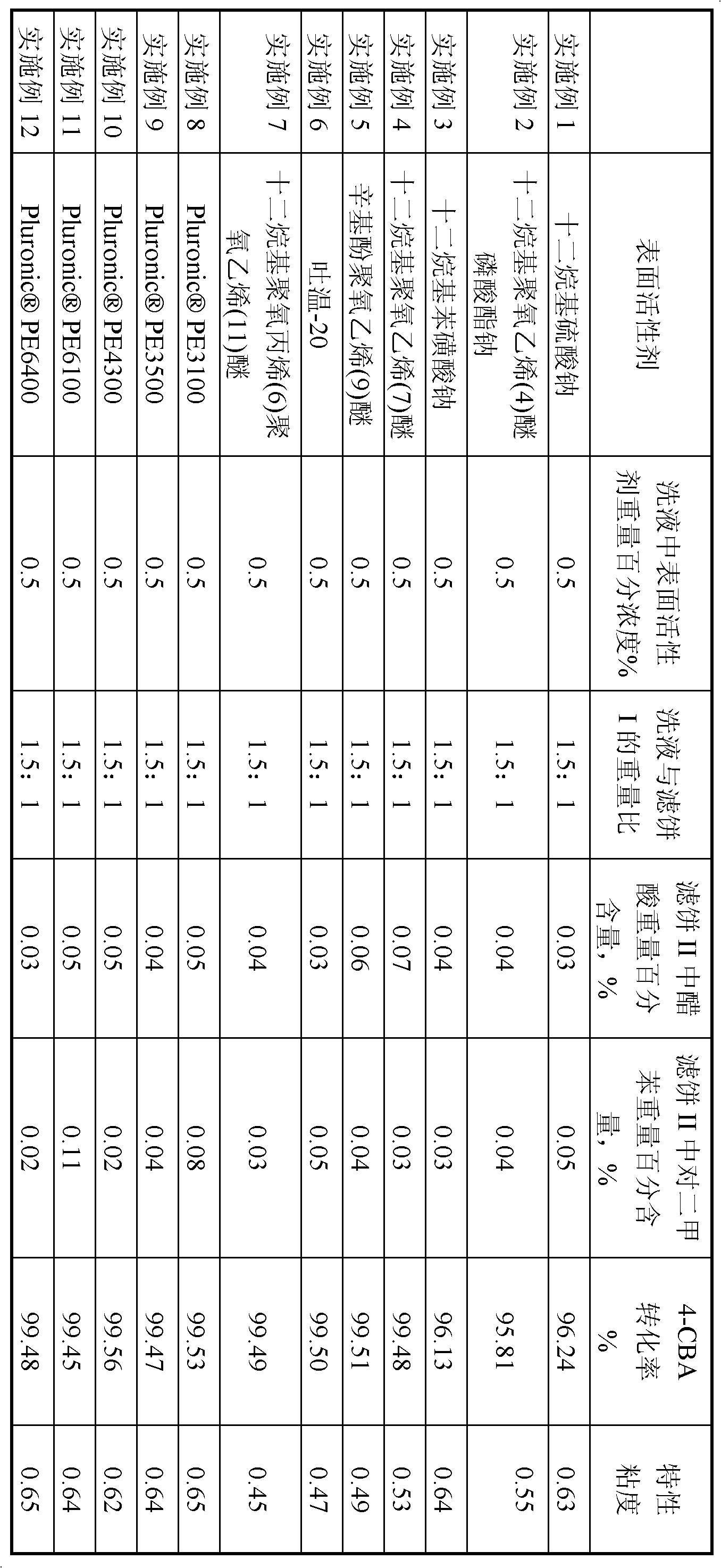

[0011] 8 kg of acetic acid slurry containing 36% crude terephthalic acid in terms of weight percent concentration from the oxidation reactor is filtered in a filter to obtain a thick terephthalic acid filter cake containing 10% of acetic acid in weight percent . Then, wash the crude terephthalic acid filter cake with 1.5 times the weight of the crude terephthalic acid filter cake and be heated to 70°C for beating and washing the crude terephthalic acid filter cake, and filter to obtain a p-xylene containing 8% by weight percentage. Crude Terephthalic Acid Cake I.

[0012] Use the sodium lauryl sulfate aqueous solution of 0.5% concentration by weight to carry out beating and washing according to the weight equivalent to 1.5 times of the terephthalic acid filter cake I, then filter and analyze the acetic acid and p-xylene in the filter cake II obtained by sampling content, and the results are shown in Table 1.

[0013] In order to check the impact of residual surfactant on the...

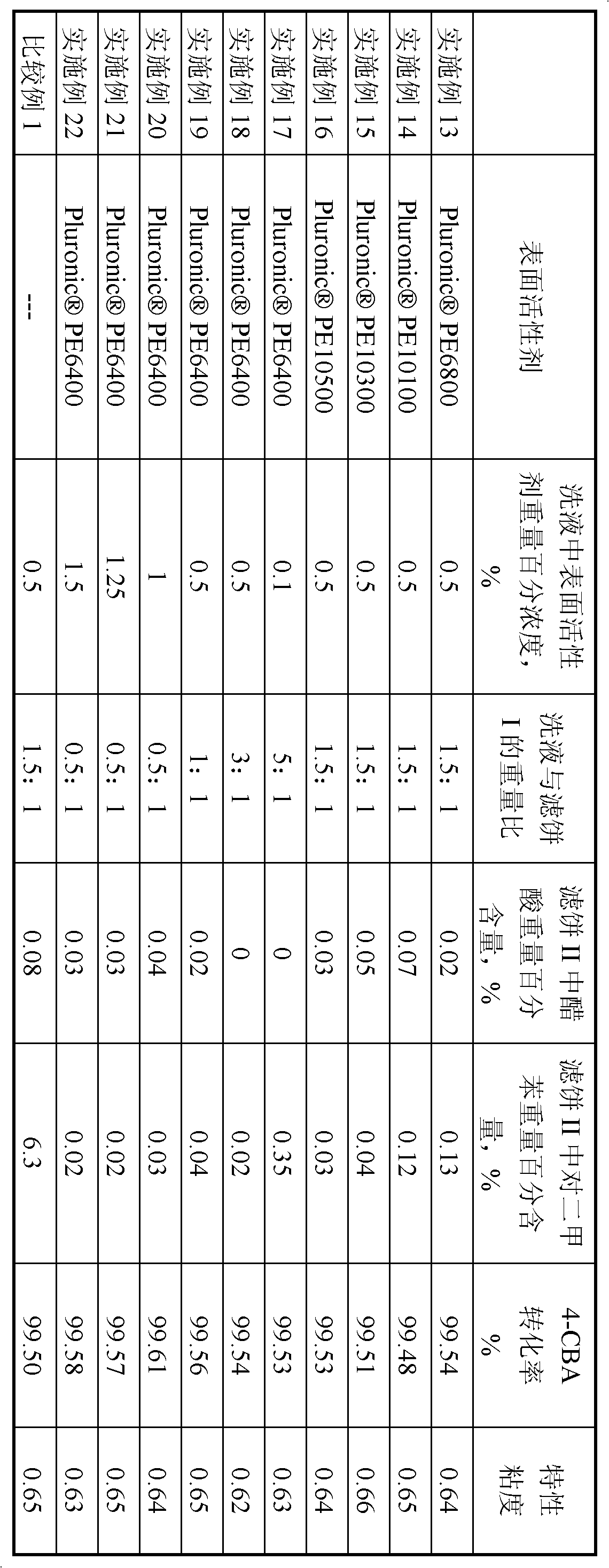

Embodiment 2~22

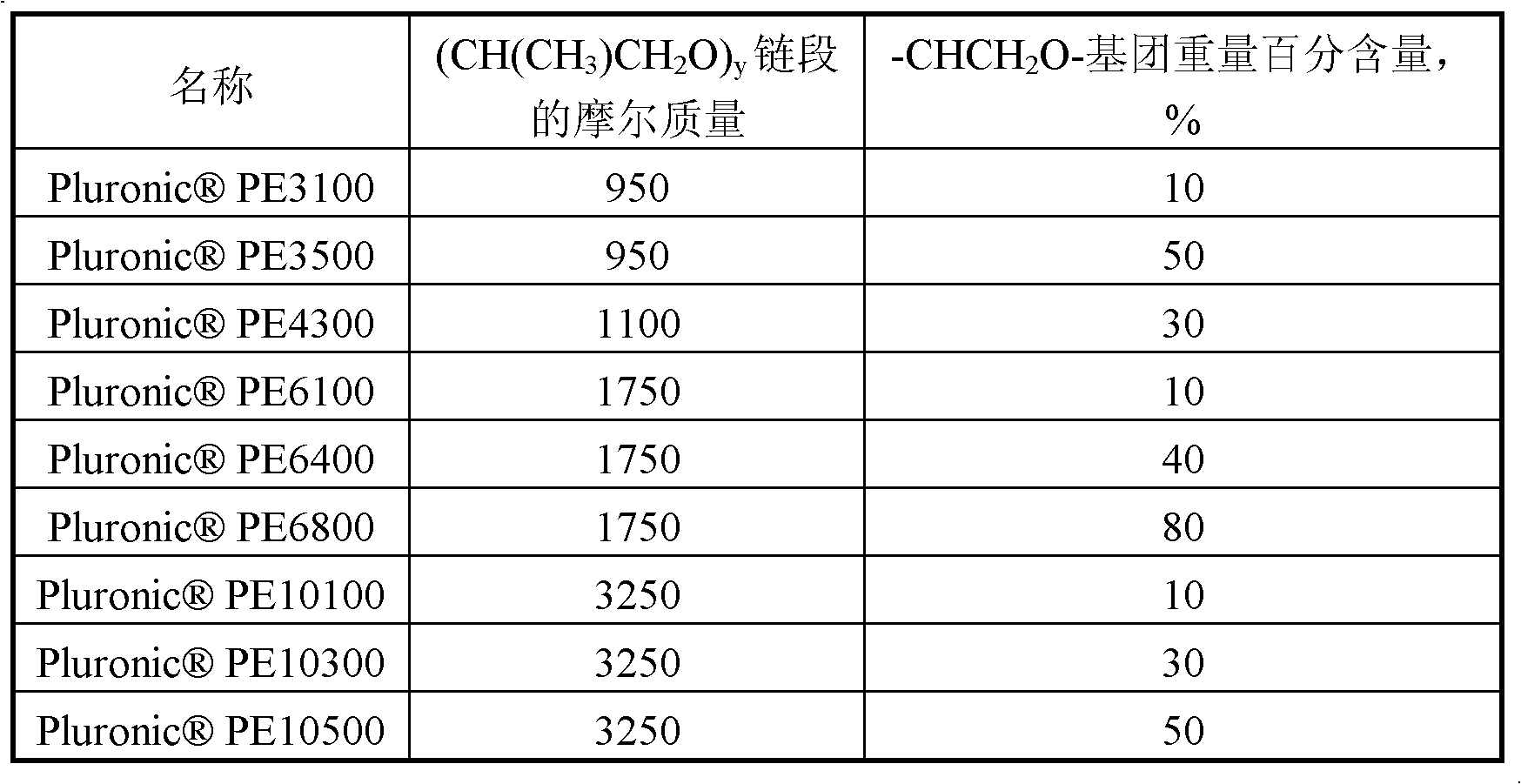

[0016] Except that the type of surfactant, the concentration of surfactant and the amount of washing liquid are different, other operating conditions are all the same as in Example 1. The changes in operating conditions and the experimental results are shown in Table 1. The tensio-active agent shown in formula III used in the embodiment is produced by BASF company A series of surfactants, in which (CH(CH 3 )CH 2 O) y The molar mass of the chain segment and -CHCH in the molecule 2 The O-group content is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com