Porous tin dioxide material as well as preparation method and application thereof

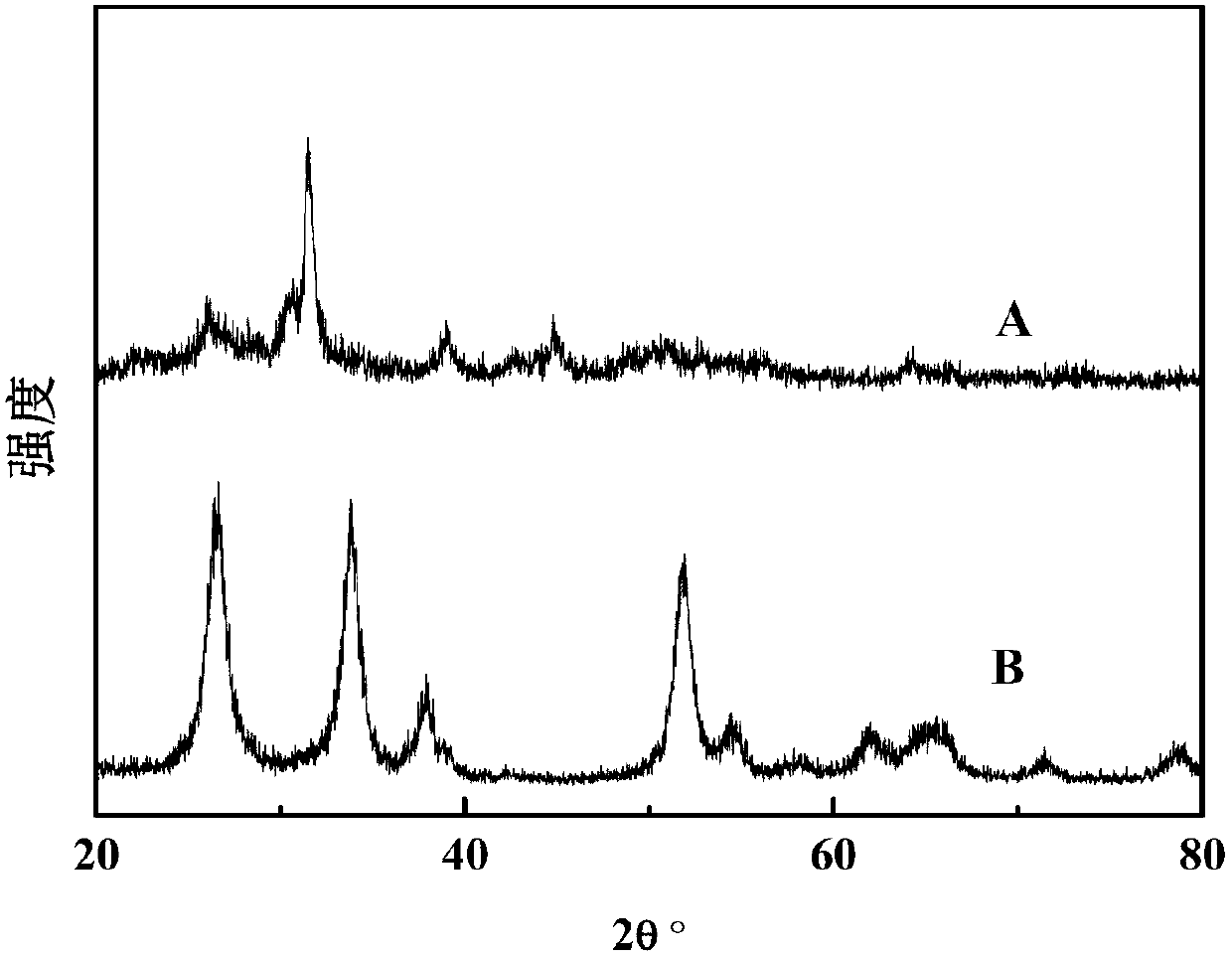

A technology of tin dioxide and stannous chloride, applied in the direction of tin oxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of response sensitivity less than 6.5, achieve novel shape, cheap and easy raw materials The effect of gaining and sensitive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

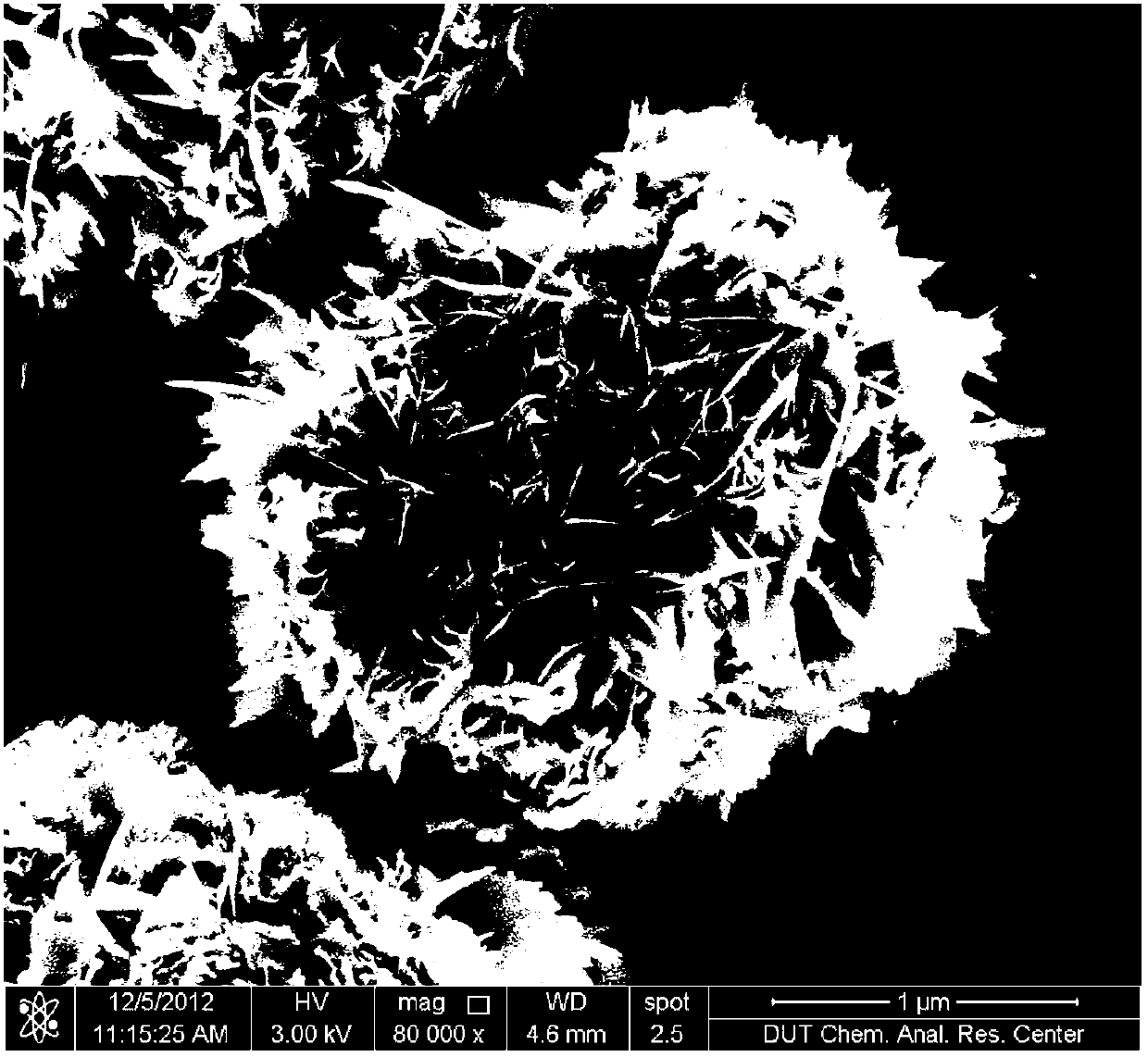

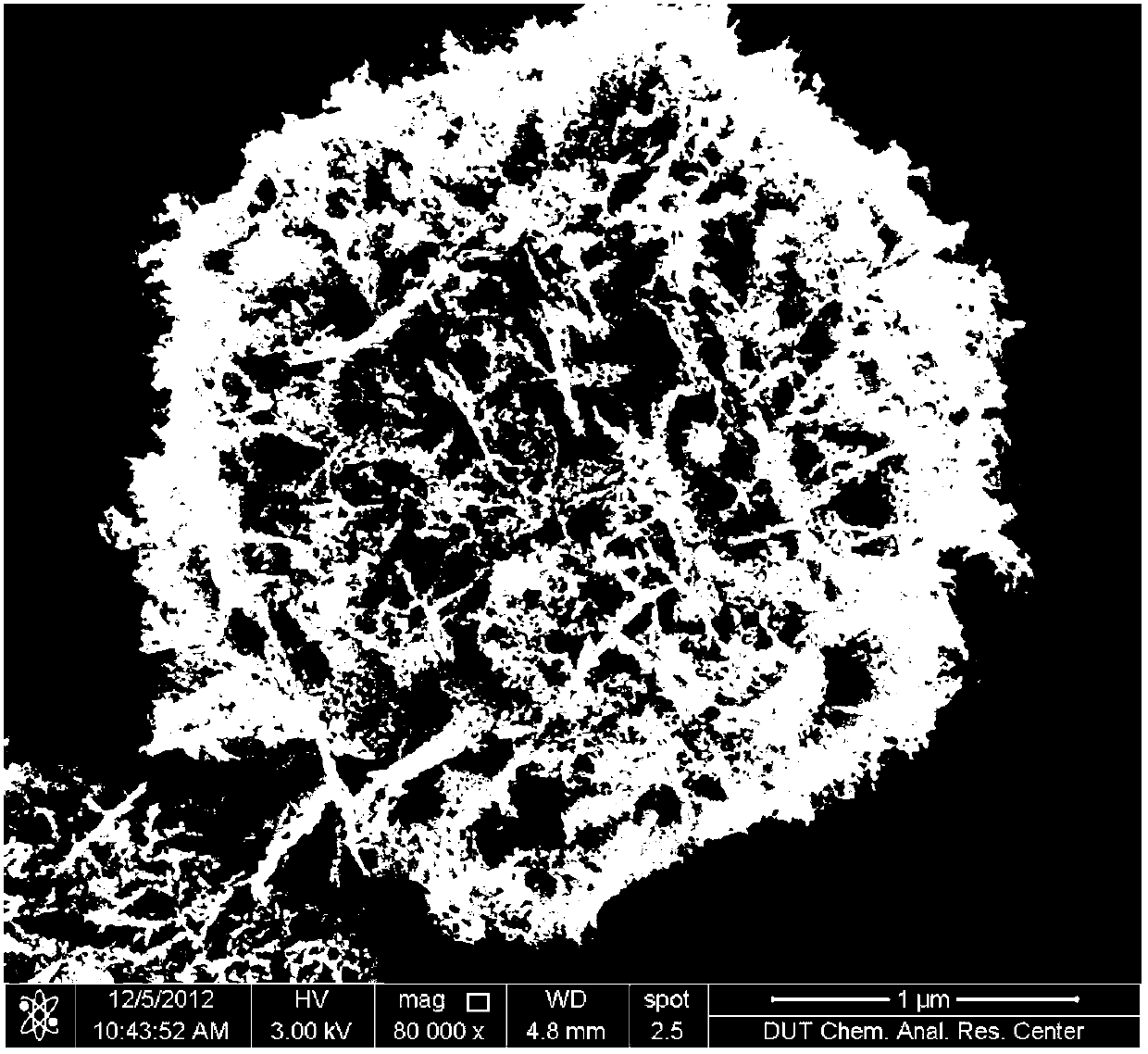

[0030] (1) Preparation of stannous sulfide with hierarchical flower-like structure by solvothermal method

[0031] ① First, dissolve 10 mmoles of stannous chloride dihydrate in 300 mL of ethylene glycol, and stir until completely dissolved. Weigh 14 mmoles of thiourea, dissolve it in the ethylene glycol solution of stannous chloride, and form a colorless transparent solution after magnetic stirring for 30 minutes. Take 30mL of the prepared solution and transfer it into a 50mL Teflon reaction kettle, place the reaction kettle in an electric constant temperature drying oven, raise it from room temperature to 200°C, and keep it at 200°C for 12 hours and then cool down naturally. The obtained black precipitate was repeatedly washed in absolute ethanol for 5 times, and then dried in a drying oven at 80°C to obtain stannous sulfide with hierarchical curdled structure.

[0032] ②Put the graded flower-like stannous sulfide obtained by the solvothermal method into an open muffle furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com