Manually-pressed type rotating mop rod

A rotary mop, hand-pressing technology, applied in the direction of cleaning carpets, floors, household appliances, etc., can solve the problems of laborious pull-up process, amplifying sliding sound, easy wear of transmission teeth, etc., to achieve easy pull-up or push-down , The effect of reducing the contact area and increasing the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

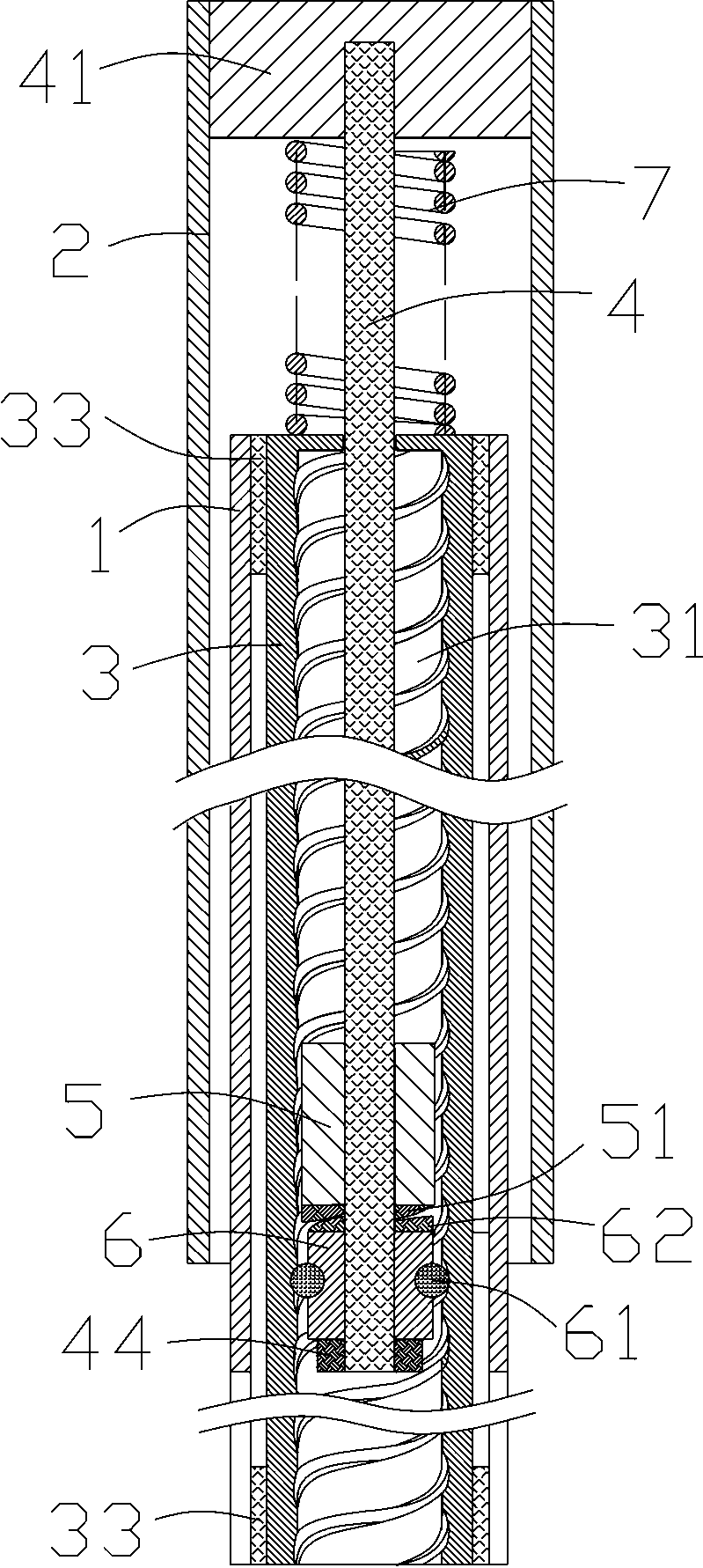

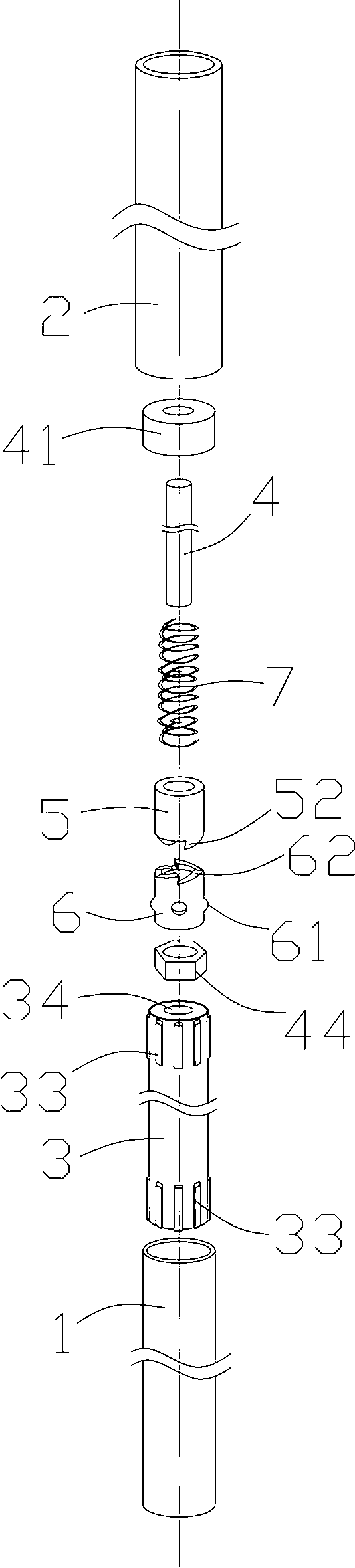

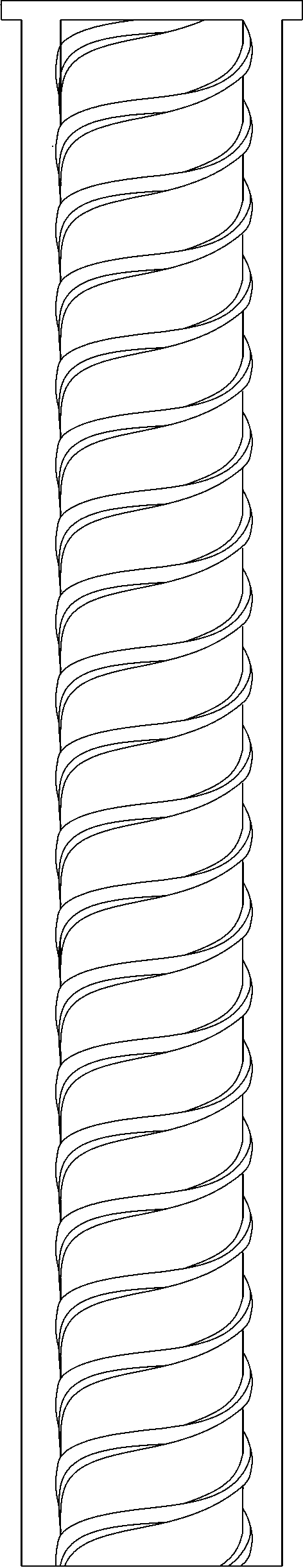

[0022] Such as figure 1 As shown, a hand-pressed rotary mop rod includes the following parts: an inner rod body 1 and an outer rod body 2 that are socketed with each other, and the lower end of one of the inner and outer rods is connected to the mop head. In this embodiment, the inner rod body is used The lower end is connected to the mop head; the rotating sleeve 3 arranged on the inner rod body 1 is fixedly connected between the outer wall of the rotating sleeve and the inner wall of the inner rod body 2, and the inner wall of the rotating sleeve 3 is provided with a spiral groove 31; The guide shaft core 4 inside the sleeve 3 and whose upper end is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com