Porous electrode assembly, liquid-flow half-cell and liquid-flow cell stack

A porous electrode and half-cell technology, applied in fuel cells, indirect fuel cells, fuel cell groups, etc., can solve the problems of low battery voltage efficiency, stack loss, high pump consumption, etc., to improve charge and discharge efficiency and reduce liquid flow Pressure difference, effect of reducing fluid flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

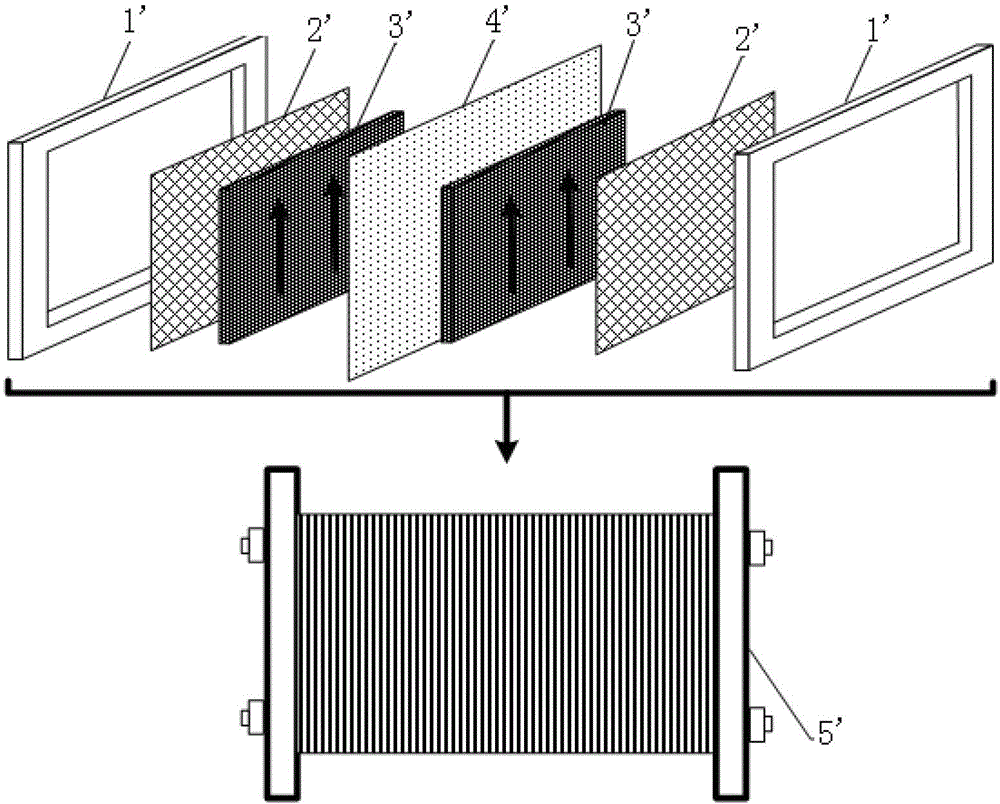

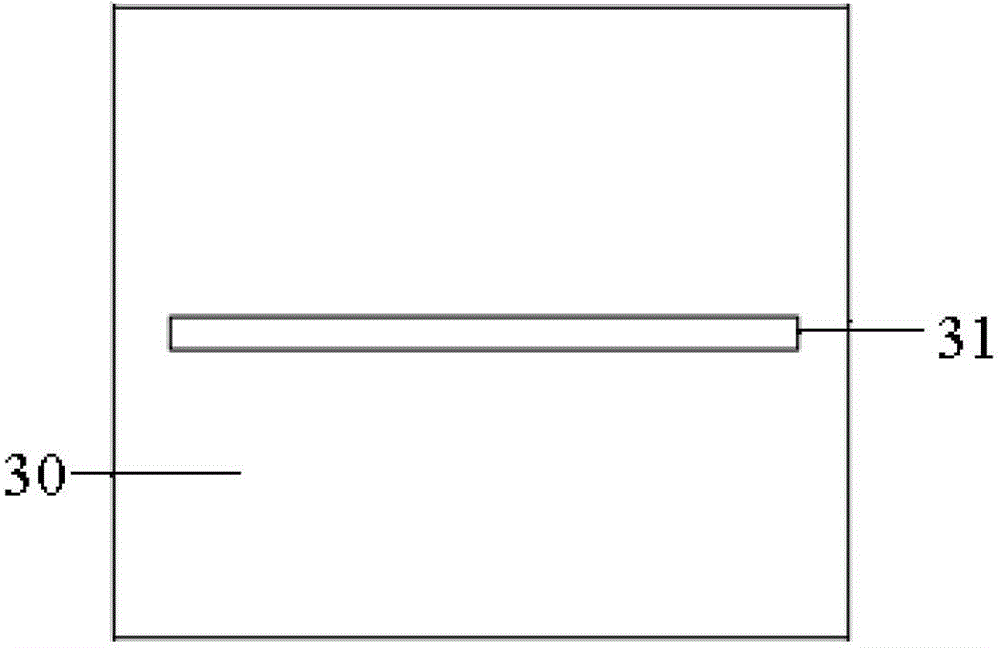

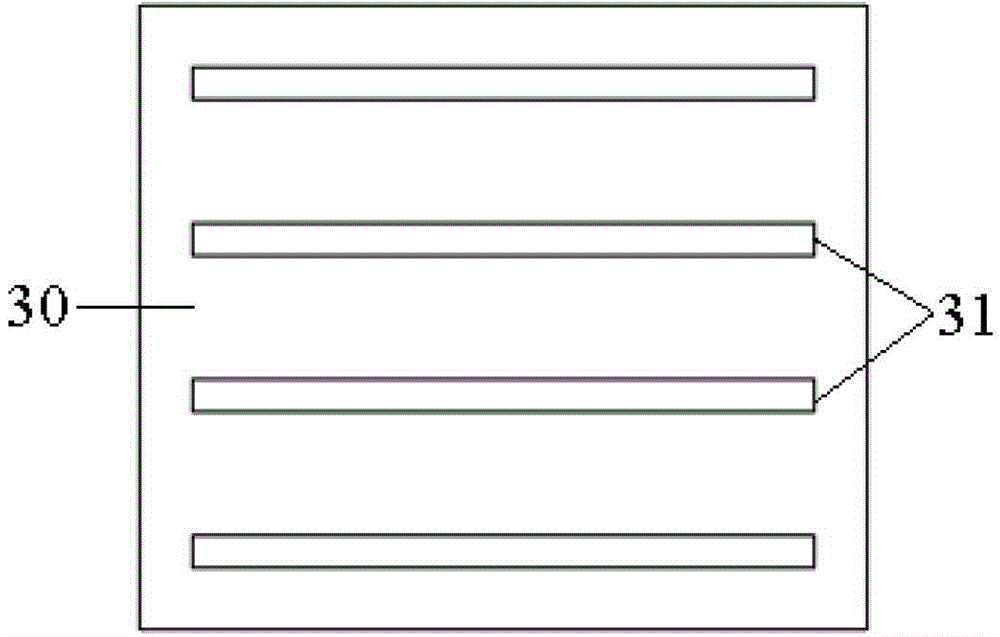

[0055] Such as Figure 2 to Figure 27 As shown, in a typical embodiment of the present invention, a porous electrode group is provided, the porous electrode group includes a plurality of stacked porous electrodes 30, wherein at least one porous electrode 30 is a flow channel with a flow channel 31 The electrode, the flow channel 31 penetrates through the thickness direction of the flow channel electrode.

[0056] The porous electrode group having the above structure, wherein at least one porous electrode 30 is a flow channel electrode with a flow channel 31 for the electrolyte to flow through inside, and the electrolyte flows through the porous electrode with the flow channel 31 under the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com