Patch type diode device structure

A device structure and diode technology, applied in the direction of electrical solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as product electrical or reliability failures, avoid product yield loss, and improve product electrical properties and reliability, avoiding the effect of connecting piece deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

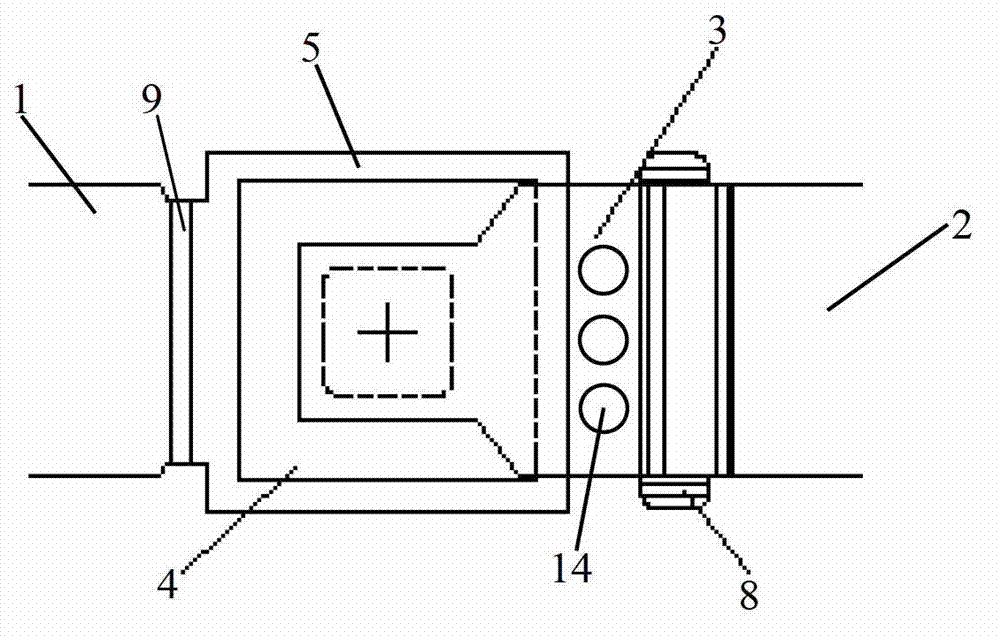

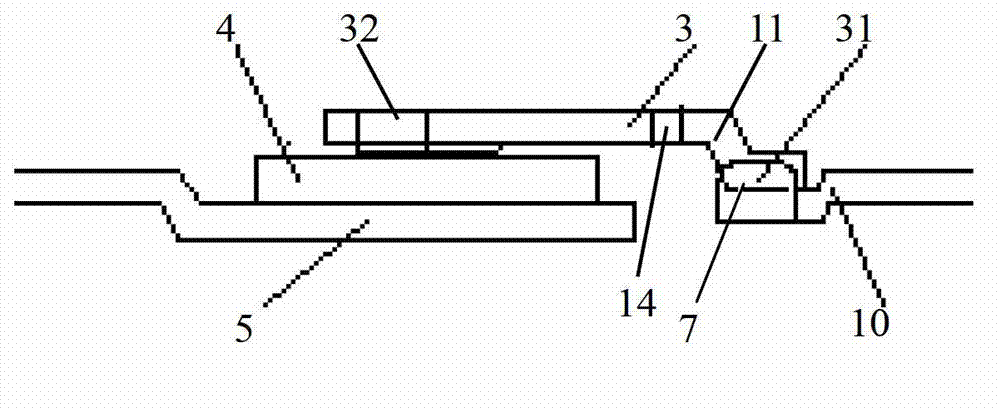

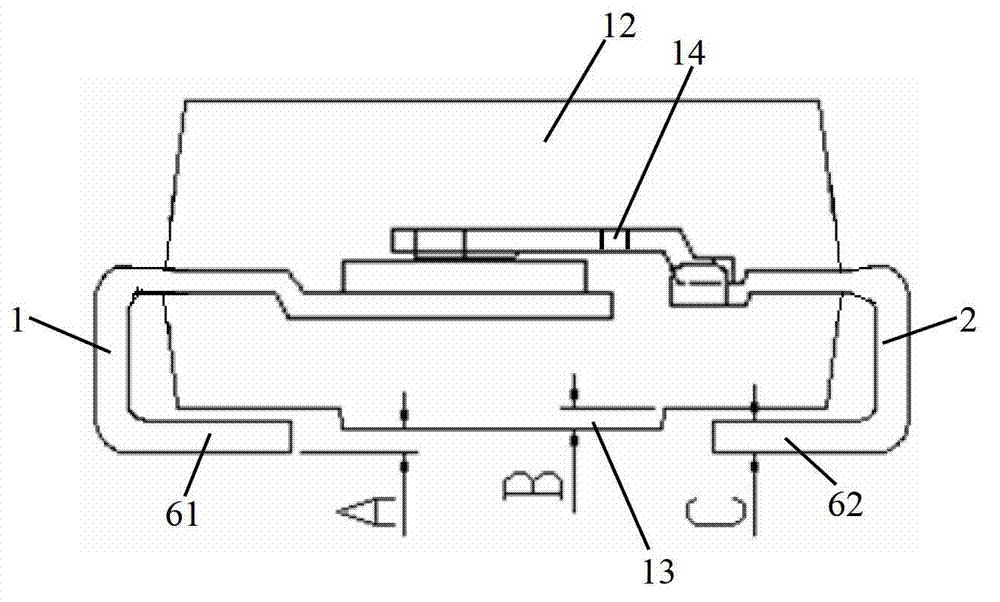

[0025] Example: a chip diode device structure, as attached Figures 1~3 As shown, it includes a first lead bar 1, a second lead bar 2, a connecting piece 3 and a diode chip 4 located in the epoxy package 12, and one end of the first lead bar 1 is a support area 5 connected to the diode chip 4, One end of the diode chip 4 is electrically connected to the support area 5 through solder paste, the other end of the first lead bar 1 is a pin area 61, and the pin area 61 of the first lead bar 1 serves as the current transmission end of the rectifier;

[0026] One end of the second lead bar 2 is a welding area 7 connected to the first welding end 31 of the connecting piece 3 , the other end of the second lead bar 2 is a pin area 62 , and the pins of the second lead bar 2 Region 62 serves as the current transfer terminal of the rectifier;

[0027] The second welding end 32 of the connecting piece 3 is electrically connected with the other end of the diode chip 4 through solder paste; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com