Jig for testing notch sensitivity of bolt

A test fixture and sensitivity technology, applied in measuring devices, strength characteristics, instruments, etc., can solve the problem of only axial load test, etc., and achieve the effect of convenient installation, convenient test operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

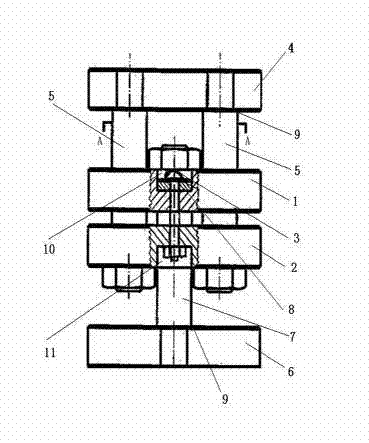

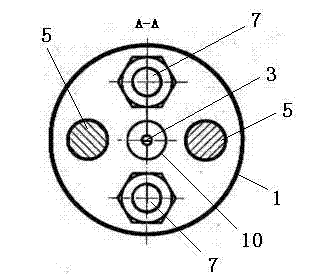

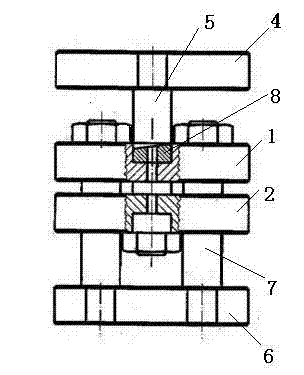

[0019] see figure 1 , 2 , 4, 5, 10, the bolt notch sensitivity test fixture includes upper and lower tensile plates 1 and 2, and there is a central hole between the upper and lower tensile plates 1 and 2 for connecting the test bolt 3; the upper and lower tensile plates 1 and 2 A test bolt 3 is connected between , 2 (connected during the test, and the nut is tightened); the upper pressure plate 4 is connected to the upper and lower tensile plates 1 and 2 through the two bolt ejectors 5 at intervals, that is, the bolt ejector 5 is two There is a stop 9 (reduced diameter) at the end, which clamps the upper pressing plate 4 and the lower pressing plate 6.

[0020] see figure 1 , 3 , the lower pressing plate 6 is connected to the lower and upper tensile plates 2 and 1 at intervals through the other two bolt push rods 7 . There are four bolt jacks in total, the two bolt jacks 5 connected with the upper pressure plate 4 are arranged in parallel, and the two bolt jacks 7 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com