Automatic opposite-angle clamping type omnidirectional rotary cantilever support

A cantilever bracket and clamping technology, applied in the direction of machine/bracket, supporting machine, mechanical equipment, etc., can solve the problems of unable to clamp, unable to realize all-round rotation in space, inconvenient to move, etc., to achieve the effect of easy clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

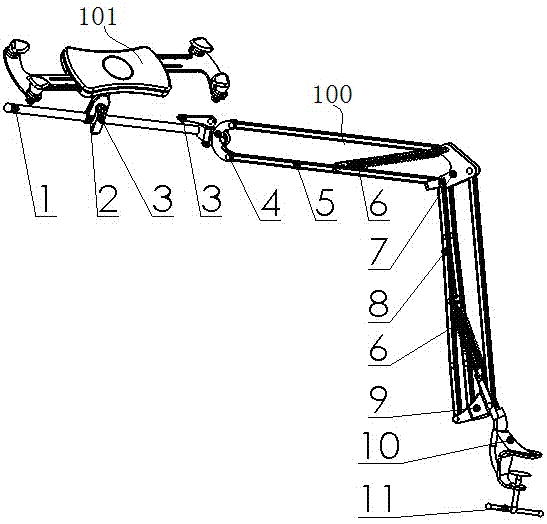

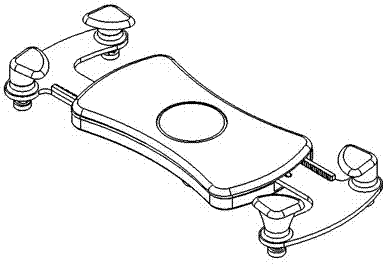

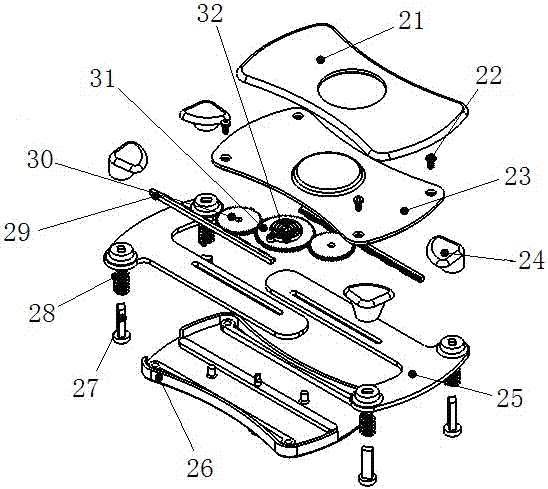

[0022] Such as figure 1 As shown, the automatic diagonal clamping omnidirectional rotating cantilever support of the present invention is composed of a universal support 100 and a clamping device 101 .

[0023] The universal bracket 100 includes a rotating rod 1, a universal clip 2, a clamping turnbuckle 3, a third link 4, a second support rod 5, a gravity balance spring 6, a second link 7, a first support rod 8, a first Link 9, fixed fixture 10, fixed rotary handle 11.

[0024] The upper and lower ends of the second link 7 are movably linked with the third link 4 and the first link 9 through the second support rod 5 and the first support rod 8 respectively, forming a four-bar linkage structure of the upper and lower arms, and the second link Between the part 7 and the second support bar 5 and between the first link 9 and the first support bar 8, a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com