Detachable pipe connector

A connector and detachable technology, which is applied in the field of detachable pipe connectors, can solve the problems of unreliable connection, low connection efficiency, and many connection procedures, and achieve reliable, safe and fast non-welding connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

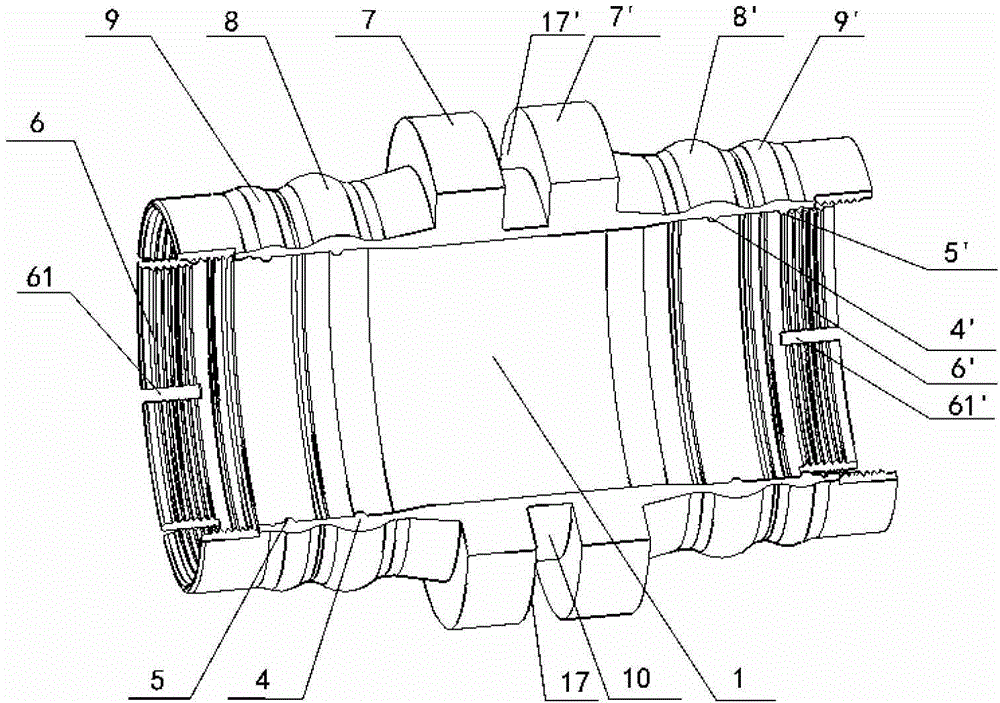

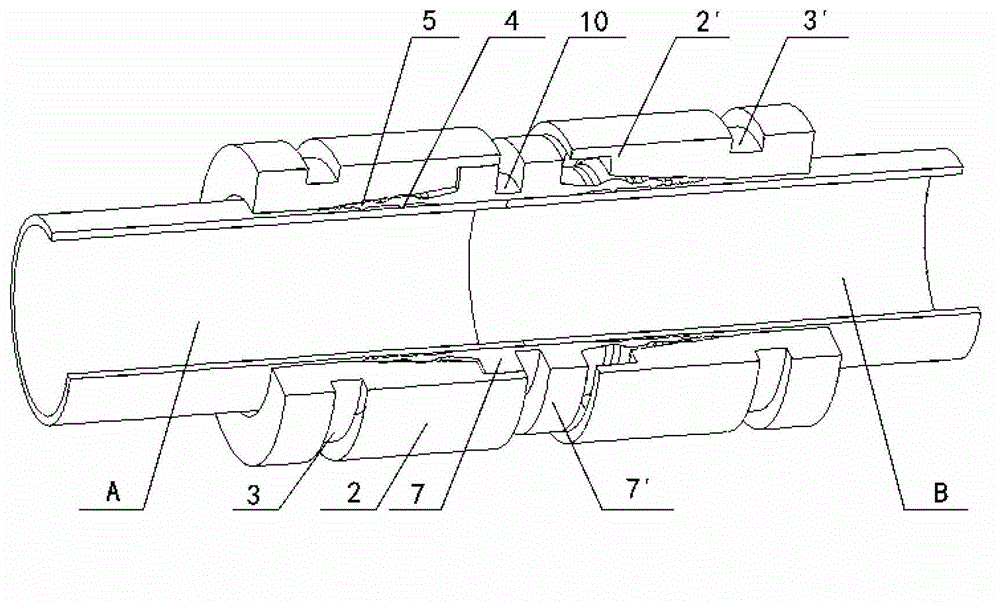

[0017] Attachment of the present invention Figure 1-3 The meanings of the symbols in are: 1 connector base; 2, 2' left and right pressure rings; 4, 4' left and right first inner protrusions; 5, 5' left and right second inner protrusions; , 6, 6' left and right ends with ring threaded section; 61, 61' the open groove on the left and right end with ring threaded section; 7, 7' left and right load bearing ring; 8, 8' left and right The first outer protrusion; 9, 9' left and right second outer protrusion; 10 claw positioning groove; A left pipe; B right pipe.

[0018] combine figure 1 and figure 2 . The detachable pipe connector of the present invention includes a connector base 1 and two pressure rings 2 and 2'; the connector base 1 is a hollow pipe body, and the two ends of the hollow pipe body extend from both ends to the middle Correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com