Pressure-bearing connecting sleeve

A technology of coupling sleeves and outer sleeves, applied in the direction of couplings, connecting members, elastic couplings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

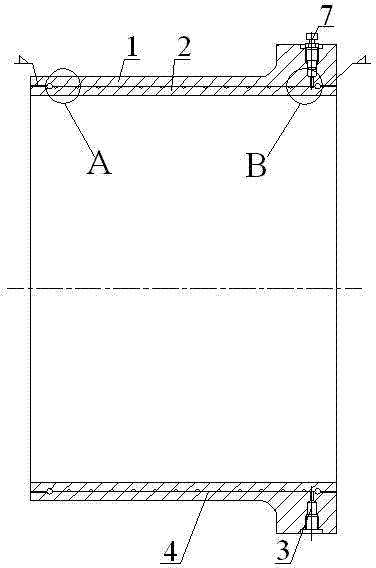

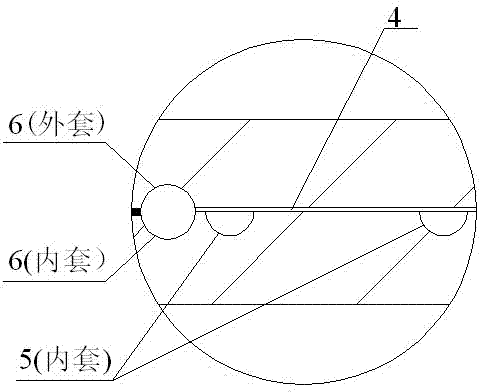

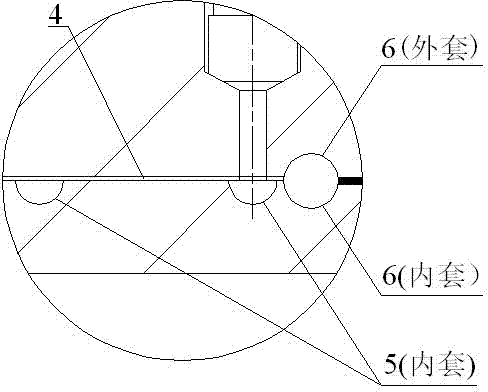

[0012] From figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 It can be seen that a pressure-bearing coupling sleeve of the present invention includes an outer sleeve 1, an inner sleeve 2, and a cavity 4 matched between the two. The outer sleeve 1 is processed with several holes 3, and the cavity 4 includes an annular groove. 6. There are two spiral grooves 5 and two annular grooves 6, which are arranged on both sides of the spiral groove 5, and the spiral groove 5 communicates with at least one of the holes 3. Wherein, the fit between the outer sleeve 1 and the inner sleeve 2 may be a clearance fit or an interference fit.

[0013] Each annular groove 6 is composed of two arc-shaped grooves respectively processed on the inner hole surface of the outer sleeve 1 and the outer circular surface of the inner sleeve 2 . The function of the annular groove 6 on the inner hole surface of the outer jacket 1 and the outer circular surface of the inner jacket 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com