Quick Installation Method of Anchor Bolts in Steel Structure Workshop

A technology of building anchor bolts and installation methods, which is applied in building construction, building material processing, construction, etc., can solve problems such as low construction efficiency, and achieve the effects of shortened operation time, high connection strength, and convenient installation and placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The quick installation method of the anchor bolts of the steel structure workshop includes the following steps:

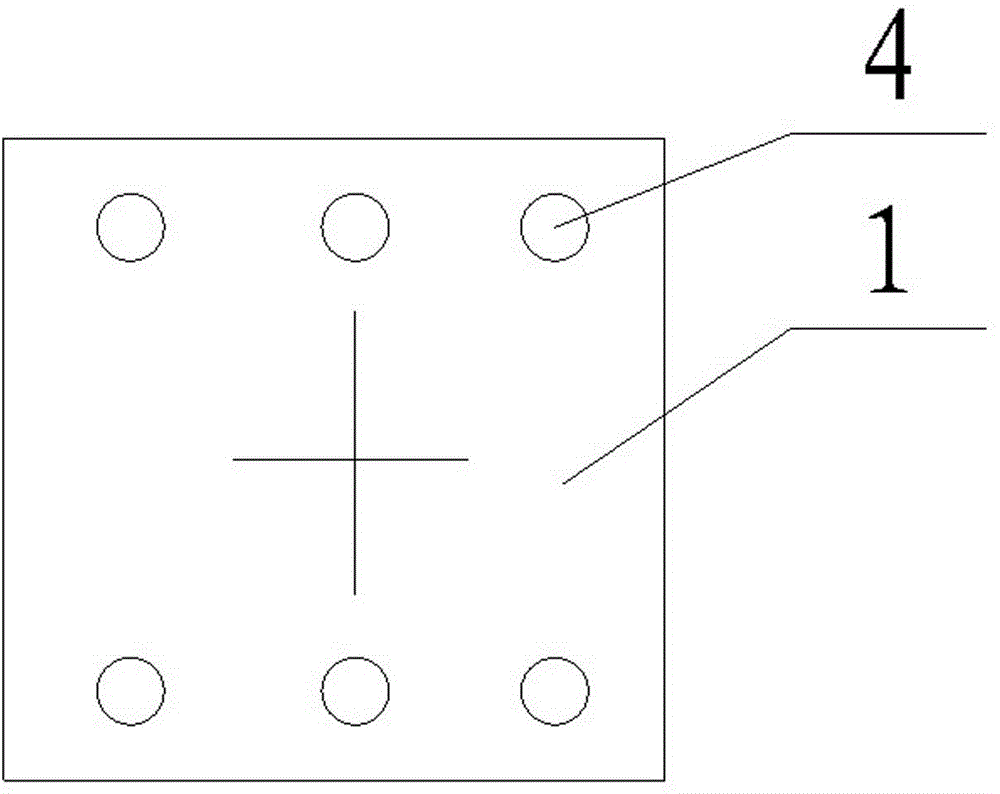

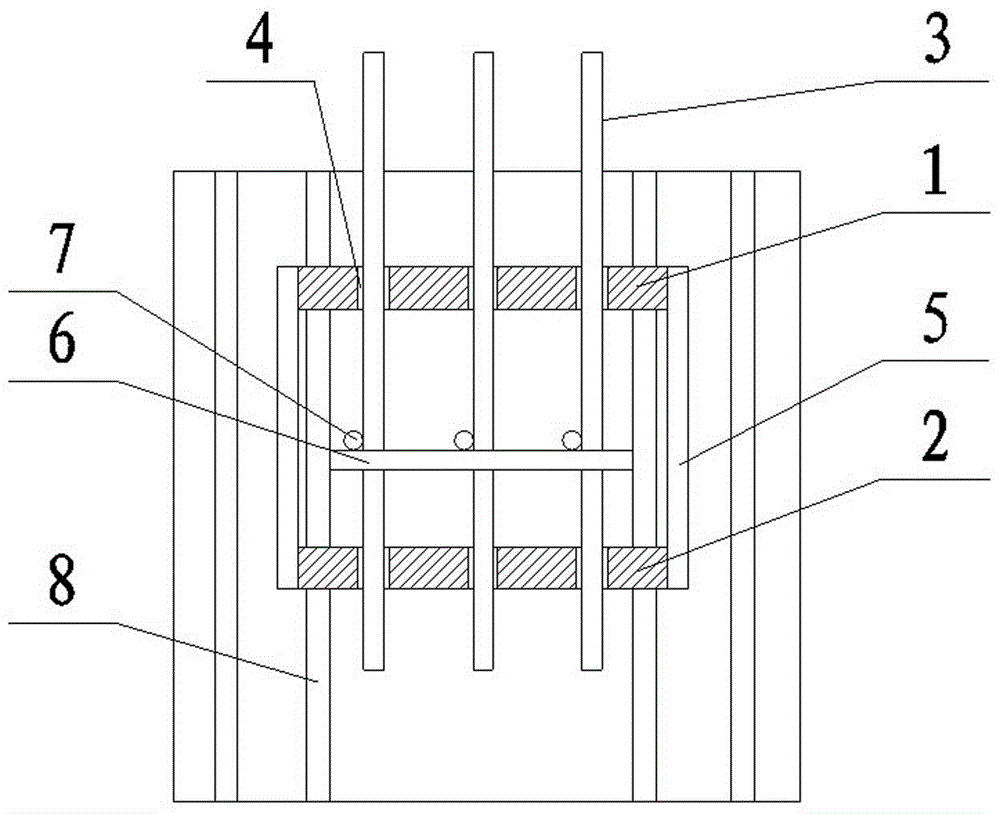

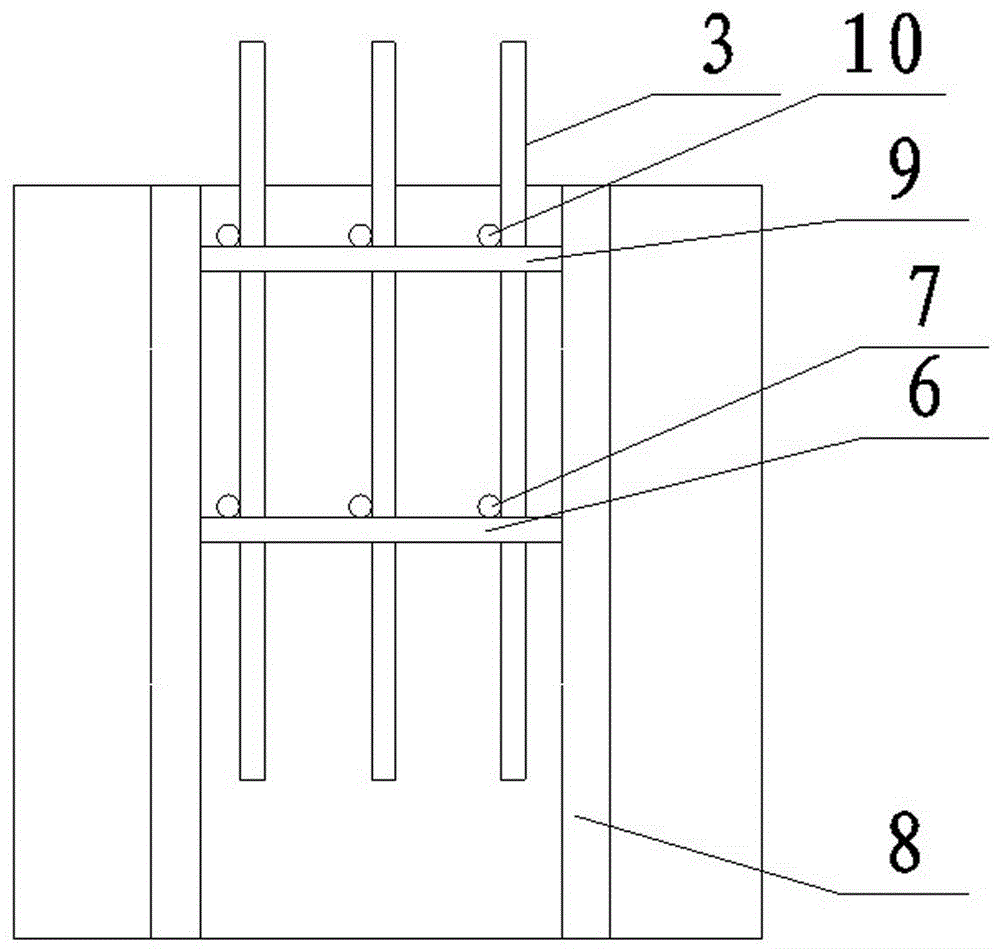

[0017] (1) Take the upper bamboo plywood 1 and the lower bamboo plywood 2 with the same shape and size, and two rows of anchor bolts 3 with diameter ratios are symmetrically opened on both sides of the transverse center line of the upper bamboo plywood 1 and the lower bamboo plywood 2. The positioning hole 4 with an outer diameter of 2-3mm (2mm, 2.5mm, 3mm), the total number of positioning holes on the upper bamboo plywood 1 and the lower bamboo plywood 2 is equal to the total number of anchor bolts; the upper bamboo plywood 1 and The positions of the positioning holes 4 on the lower bamboo plywood 2 correspond to each other;

[0018] (2) On the outer walls of the upper bamboo plywood 1 and the lower bamboo plywood 2, vertically fix and reinforce the square wood 5 so as to connect the upper bamboo plywood 1 and the lower bamboo plywood 2 together, and place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com