Etching solution, replenishing solution, and method of forming copper wiring

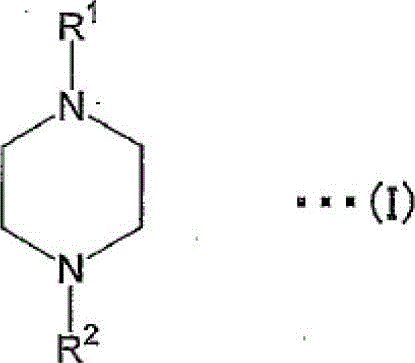

A technology of etching solution and divalent copper ions, which is used in the removal of conductive materials by chemical/electrolytic methods, electrical components, and printed circuit manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Next, examples and comparative examples of the present invention will be described. It should be noted that the present invention is not limited and explained by the following examples.

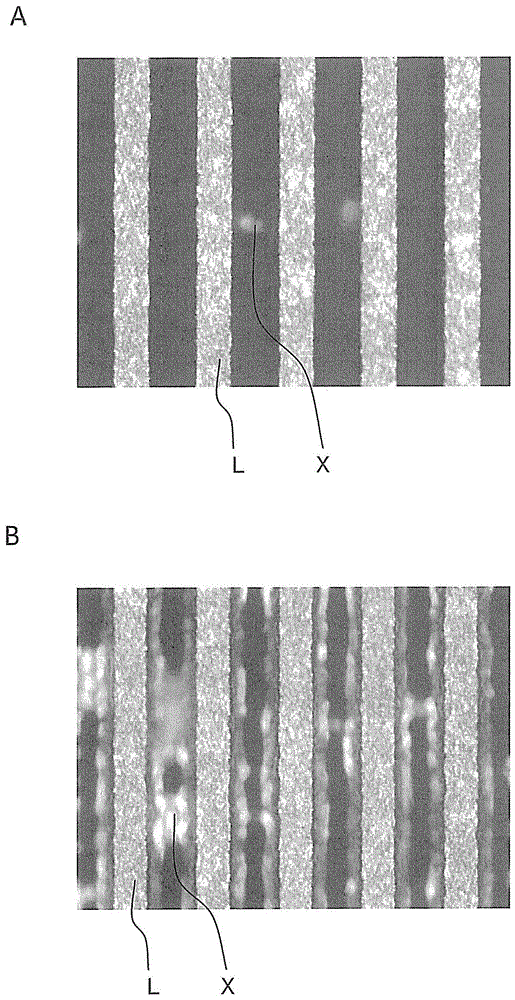

[0057] Each etchant having the composition shown in Tables 1 to 3 was prepared, etched under the conditions described below, and each item was evaluated according to the evaluation method described below. In addition, in each etching liquid of the composition shown in Tables 1-3, the balance was ion-exchange water. In addition, the concentration of hydrochloric acid shown in Tables 1 to 3 is the concentration as hydrogen chloride.

[0058] (Test substrate used)

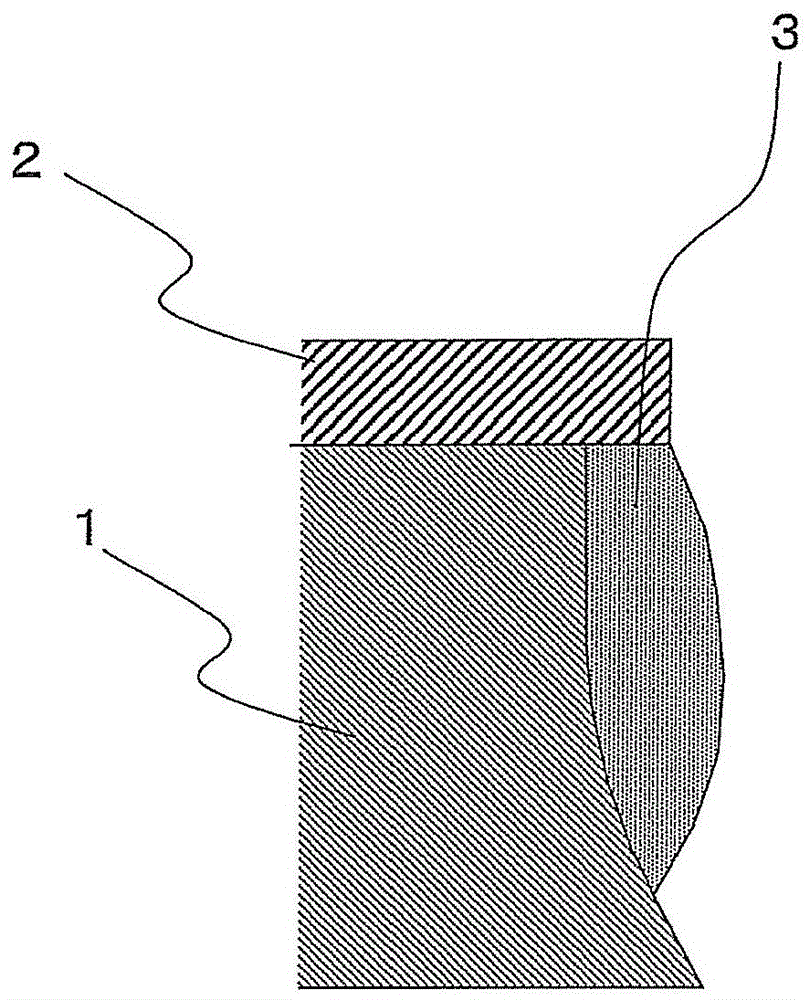

[0059] Prepare a copper-clad laminate laminated with 3 μm-thick copper foil (manufactured by Mitsui Metal Mining Co., Ltd., trade name: MicroThin EX), and treat the copper with a treatment solution containing a palladium catalyst (manufactured by Okuno Pharmaceutical Co., Ltd., trade name: ADDCOPPER SERIES) After foiling, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com