Additive for production of diesel from condensate oil and preparation method thereof

A technology for condensate oil and additives, which is applied in the field of diesel additive preparation, can solve the problem of no additives, etc., and achieve the effects of proper ratio, easy start-up and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

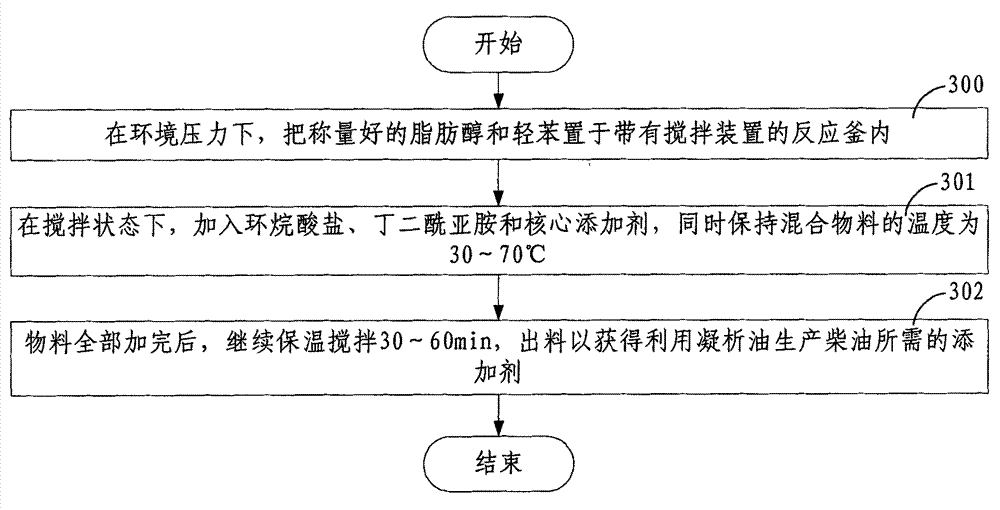

[0058] Please see also figure 1 A method for preparing additives required for producing diesel oil from condensate oil, comprising the following steps:

[0059] Step S300, placing the weighed fatty alcohol and light benzene in a reactor with a stirring device under ambient pressure, wherein the ambient pressure refers to the natural atmospheric pressure in the area where the production facility is located;

[0060] Step S301, under stirring, add naphthenate, succinimide and core additives, while keeping the temperature of the mixed material at 30-70°C, wherein the preferred temperature is 40-50°C, wherein fatty alcohol, light The weight percent of benzene, naphthenate, succinimide, core additive is:

[0061] Fatty alcohol 10-55%;

[0062] Light benzene 10-30%;

[0063]Naphthenate 10-30%;

[0064] Succinimide 5-10%;

[0065] Core additives 10-30%;

[0066] Step S302, after all the materials are added, the heat preservation and stirring are continued for 30-60 minutes, and...

Embodiment 1

[0079] The additives used to produce ordinary diesel oil with condensate oil as the main raw material, its components and the weight percentage of each component are:

[0080]

[0081]

[0082] Described core additive, its component and the weight percent of each component are:

[0083]

[0084] The preparation method of the additives used in the production of ordinary diesel oil with condensate oil as the main raw material is as follows:

[0085] Under ambient pressure, put weighed isopropanol and toluene in a reactor with a stirring device; under stirring, slowly add sodium naphthenate, succinimide, and core additives while keeping the mixture The temperature is 40°C; after all the materials are added, continue to keep warm and stir for 60 minutes, and discharge the materials to obtain the additives required for the production of diesel oil from condensate oil.

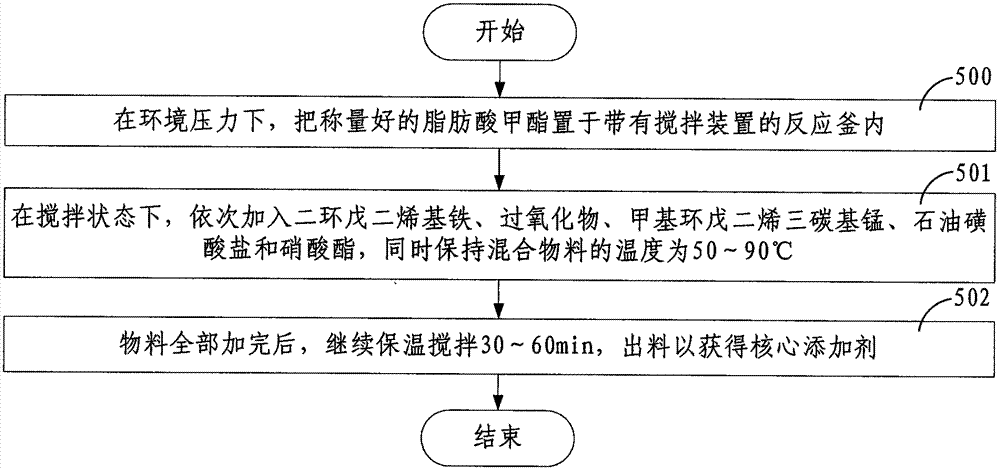

[0086] The preparation method of described core additive is as follows:

[0087] Under ambient pressur...

Embodiment 2

[0089] The additives used to produce ordinary diesel oil with condensate oil as the main raw material, its components and the weight percentage of each component are:

[0090]

[0091] Described core additive, its component and the weight percent of each component are:

[0092]

[0093] The preparation method of the additives used in the production of ordinary diesel oil with condensate oil as the main raw material is as follows:

[0094] Under ambient pressure, put the weighed n-butanol and toluene in a reaction kettle with a stirring device; under stirring, slowly add barium naphthenate, succinimide, and core additives, while keeping the mixed materials The temperature is 50°C; after all the materials are added, continue to keep warm and stir for 40 minutes, and discharge the materials to obtain the additives required for the production of diesel oil from condensate.

[0095] The preparation method of described core additive is as follows:

[0096] Under ambient pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com