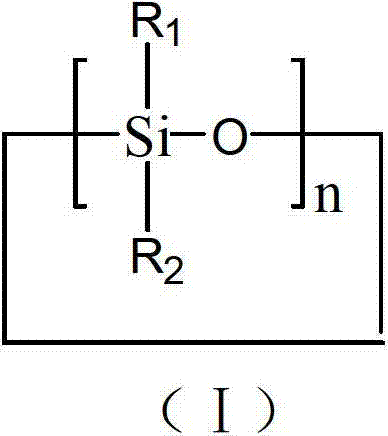

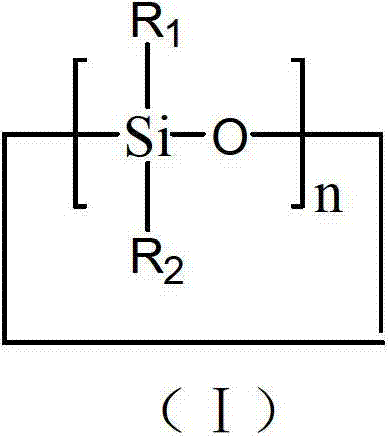

Film-forming polysiloxane emulsion and preparation method thereof

A technology of polysiloxane emulsion and polysiloxane, which is applied in the direction of coating, etc., can solve the problems of tin compound toxicity, etc., and achieve the effects of high conversion rate, improved use safety, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Add 3.4g of octadecyltrimethylammonium chloride and 6.2g of isomeric tridecyl alcohol polyoxyethylene ether (the number of moles of added ethylene oxide = 7) into a 500mL glass, and use 109g of water Dissolve, after fully dissolved, add 57.4g octamethylcyclotetrasiloxane (D4), stir to make it evenly mixed, and then shear at high speed (5000 rpm) in a shear emulsification mixer for 10 minutes to form silicone Oxane monomer pre-emulsion: transfer the organosilicon monomer pre-emulsion to a high-pressure homogenizer, and homogenize for 1 minute under a homogeneous pressure of 30Mpa to form an organosiloxane monomer emulsion.

[0044] (2) Heat the organosiloxane monomer emulsion to 80°C, add 10g of 10wt% potassium hydroxide solution, react for 6 hours, cool to 40°C, add 1.2g of octadecyltrimethylammonium chloride and 11.4g of four Ethoxysilane, polymerized for 3 hours, cooled to 25° C., and then added 1.2 g of acetic acid to neutralize the emulsion to neutral to obtain ...

Embodiment 2

[0047] (1) Add 3.4g of octadecyltrimethylammonium chloride and 6.2g of isomeric tridecyl alcohol polyoxyethylene ether (the number of moles of added ethylene oxide = 7) to a 500mL glass cup, and use 112.8g Dissolve in water, after fully dissolved, add 57.4g octamethylcyclotetrasiloxane (D4), stir to make it evenly mixed, and then shear at high speed (5000 rpm) in a shear emulsification mixer for 10 minutes to form organic Silicone monomer pre-emulsion: transfer the organosilicon monomer pre-emulsion to a high-pressure homogenizer, and homogenize for 1 minute under a homogeneous pressure of 30Mpa to form an organosiloxane monomer emulsion.

[0048] (2) Heat the organosiloxane monomer emulsion to 90°C, add 10g of 10wt% potassium hydroxide solution, react for 6 hours, cool to 40°C, add 1.2g of octadecyltrimethylammonium chloride and 7.6g of four Ethoxysilane, polymerized for 3 hours, cooled to 20°C, then added 1.2g of acetic acid to neutralize the emulsion to neutral to obtain a ...

Embodiment 3

[0051] (1) Add 3.4g of octadecyltrimethylammonium chloride and 6.2g of isomeric tridecyl alcohol polyoxyethylene ether (the number of moles of added ethylene oxide = 7) into a 500mL glass cup, and use 116.6g Dissolve in water, after fully dissolved, add 57.4g octamethylcyclotetrasiloxane (D4), stir to make it evenly mixed, and then shear at high speed (5000 rpm) in a shear emulsification mixer for 10 minutes to form organic Silicone monomer pre-emulsion: transfer the organosilicon monomer pre-emulsion to a high-pressure homogenizer, and homogenize for 1 minute under a homogeneous pressure of 30Mpa to form an organosiloxane monomer emulsion.

[0052] (2) Heat the organosiloxane monomer emulsion to 70°C, add 10g of 10wt% potassium hydroxide solution, react for 6 hours, cool to 40°C, add 1.2g of octadecyltrimethylammonium chloride and 3.8g of four Ethoxysilane, polymerized for 3 hours, cooled to 25° C., and then added 1.2 g of acetic acid to neutralize the emulsion to neutral to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com