Bobbin pressing device

A yarn-pressing tube and yarn-pressing technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, can solve problems such as spindle damage, low production efficiency, and high labor intensity, and achieve the effect of shortening the stroke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

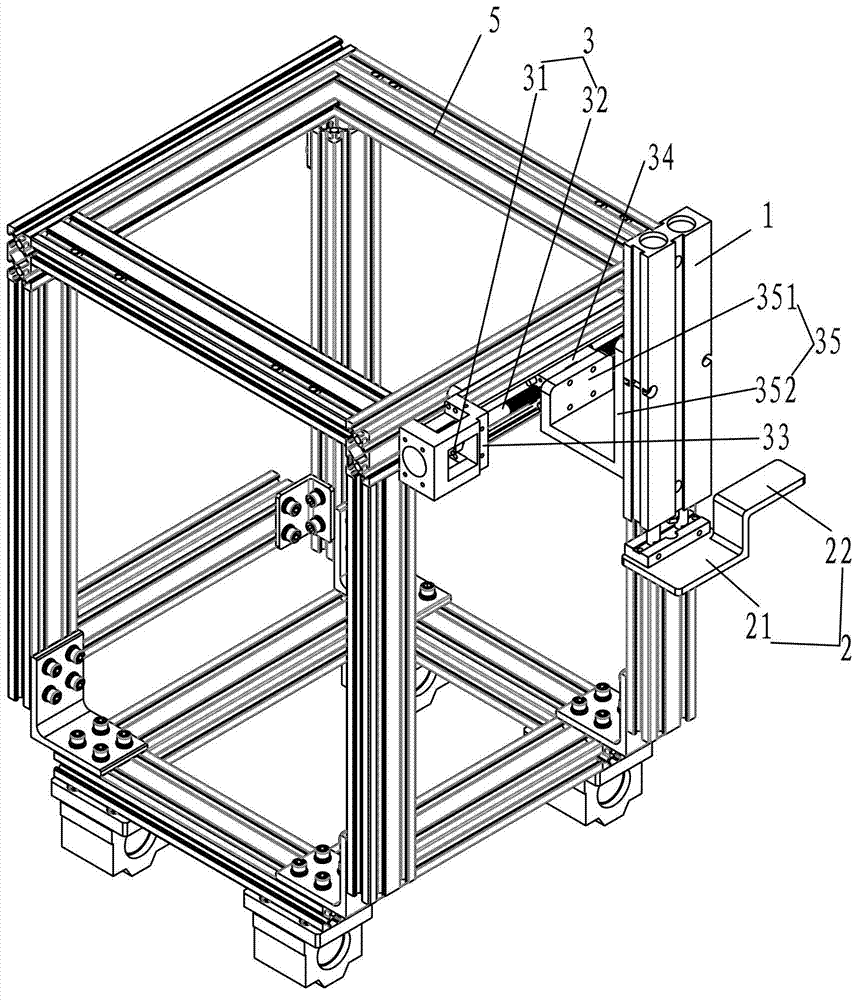

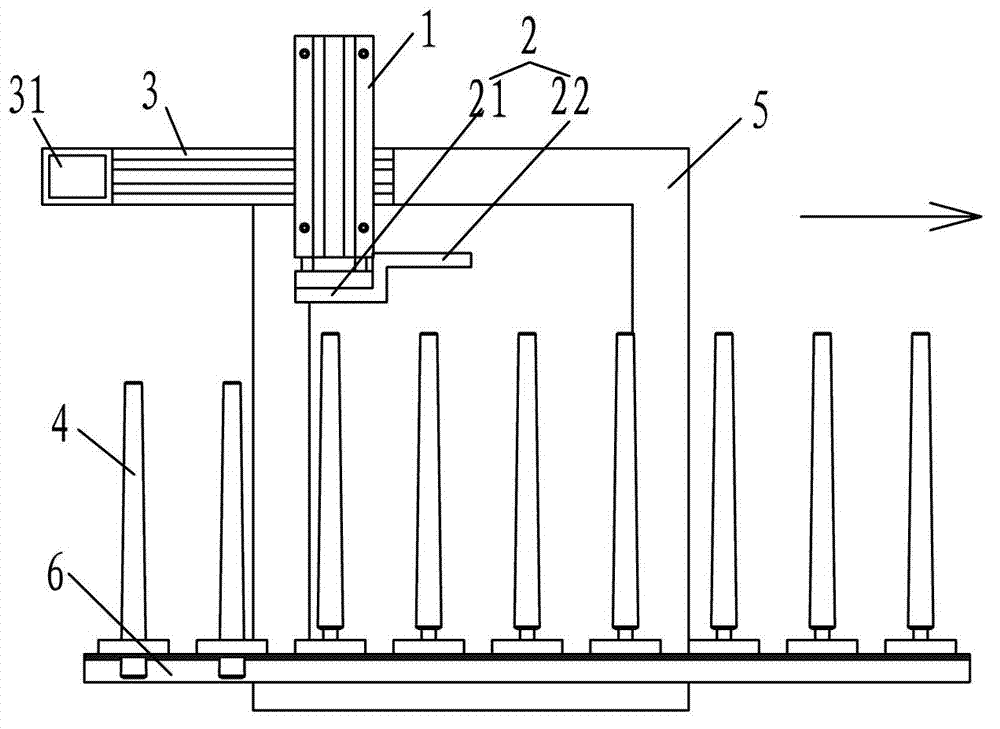

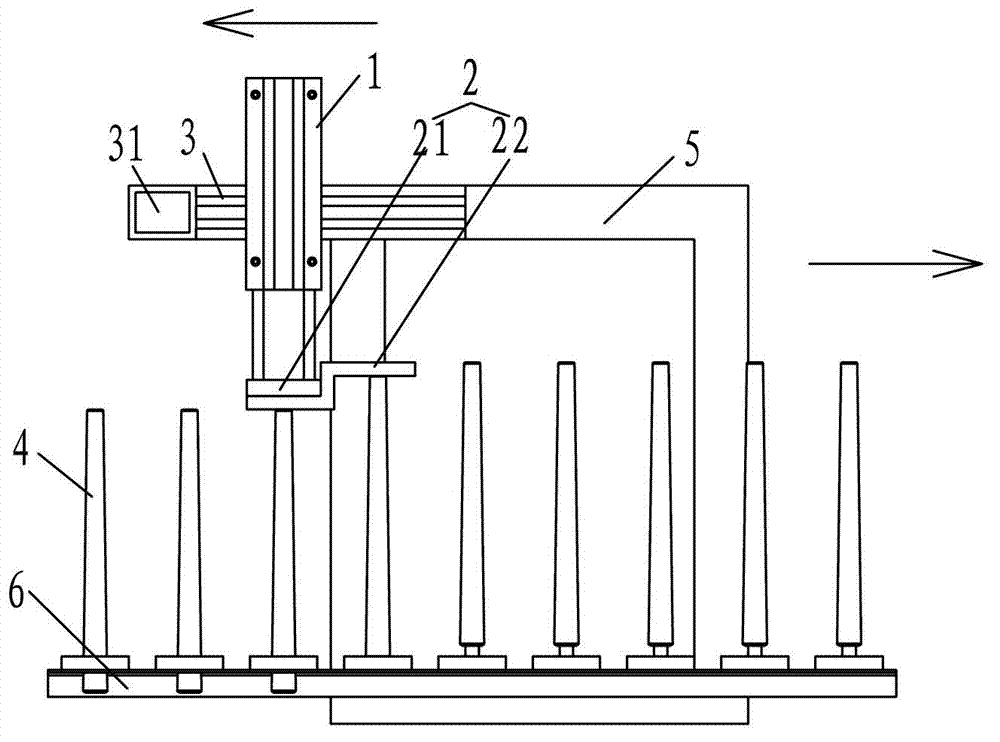

[0012] Such as figure 1 , 2 As shown, the yarn pressing tube device of the present invention includes a cylinder 1, a pressing block 2, and a control module 3. The pressing block 2 is made of an elastic material, and the pressing block 2 includes first and second pressing plates 21, 22 and a gap between the two pressing plates. Connecting plate, the second pressure plate 22 is located on the right side and the second pressure plate 22 is higher than the first pressure plate 21, the first pressure plate 21 is fixed on the piston rod of the cylinder 1, the cylinder 1 is connected to the control module 3, and the control module 3 Under the action of the cylinder 1, the cylinder 1 moves left and right along the arrangement direction of the empty bobbin 4. The control module 3 is set on the doffing device 5. The control module 3 includes a motor 31 and a lead screw 32. The motor 31 is fixed on the doffing device 5. , the leading screw 32 is connected to the output shaft of the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com