Flat resistance fiber air pipe and train using the same

An air duct and fiber technology, which is applied in the field of anti-slack fiber air ducts and the trains in which they are applied, can solve the problems of complex structure of air supply air ducts, unfavorable high-speed safe operation, and heavy material of air supply air ducts, etc. Convenience, lowering the center of gravity of the vehicle, and uniform air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

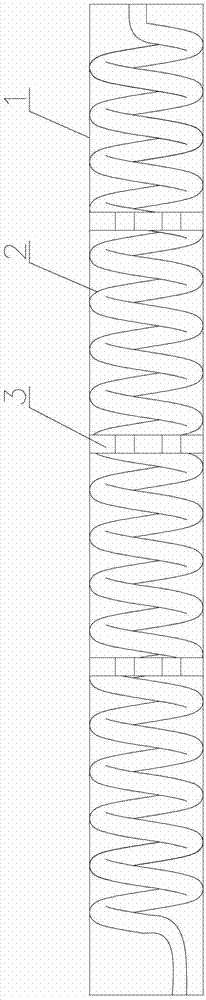

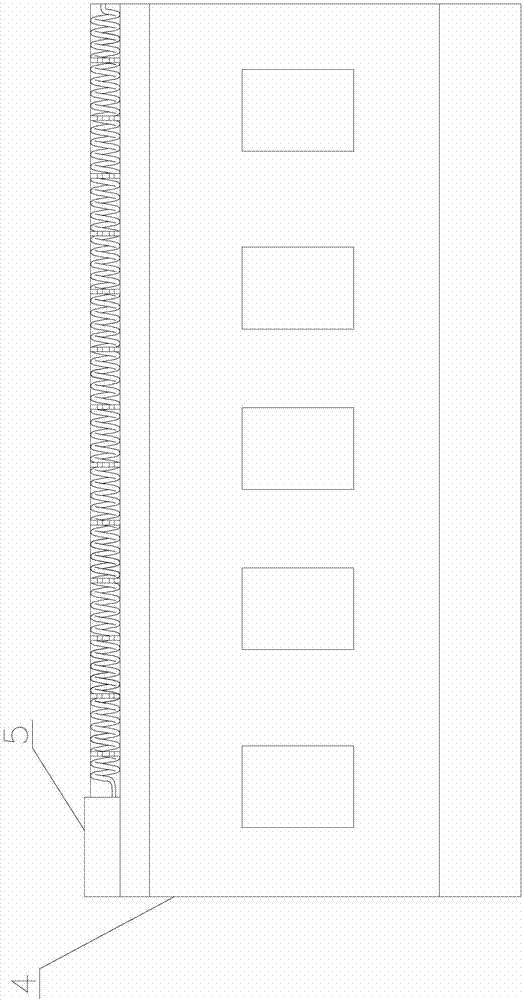

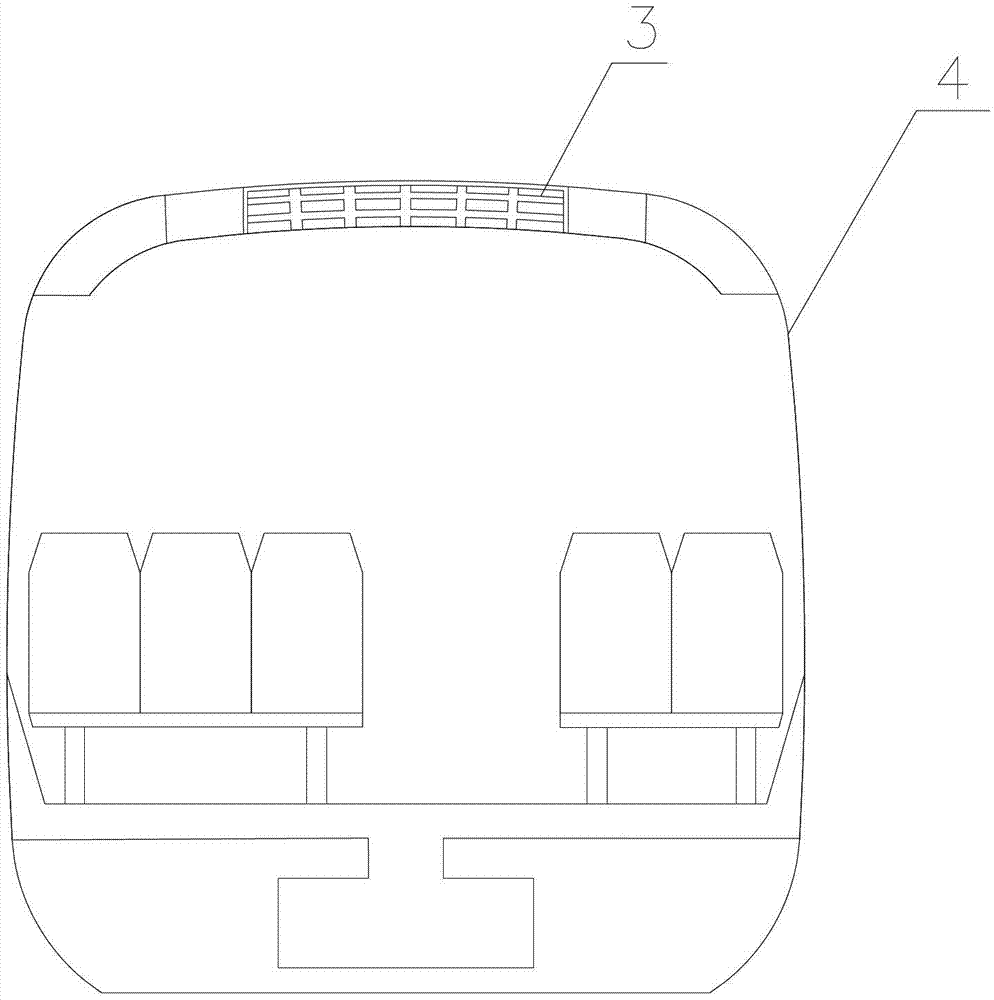

[0018] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0019] Such as figure 1 As shown, the present invention provides an anti-collapsing fiber air duct, including an air duct main body 1 made of a flame-retardant material, and a fiber micro-duct 2 for supporting the air duct main body 1 from the inside is arranged inside the air duct main body 1, The fiber micro-duct 2 is a sealed elongated duct. The fiber micro-duct 2 is made of airtight fiber material and filled with air.

[0020] One end of the fiber micro-pipe 2 has an opening for filling and discharging air and a plug to close the opening, then the fiber micro-pipe 2 will dry up due to unfilled gas, which is convenient for construction and carrying. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com