Intramode butt fusion type secondary processing method

A secondary processing and welding technology, applied in coating and other directions, can solve the problems of consuming manpower and material resources, plant space, increasing investment costs, welding, etc., and achieving the effect of saving manpower and material resources, improving stability and coordination tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

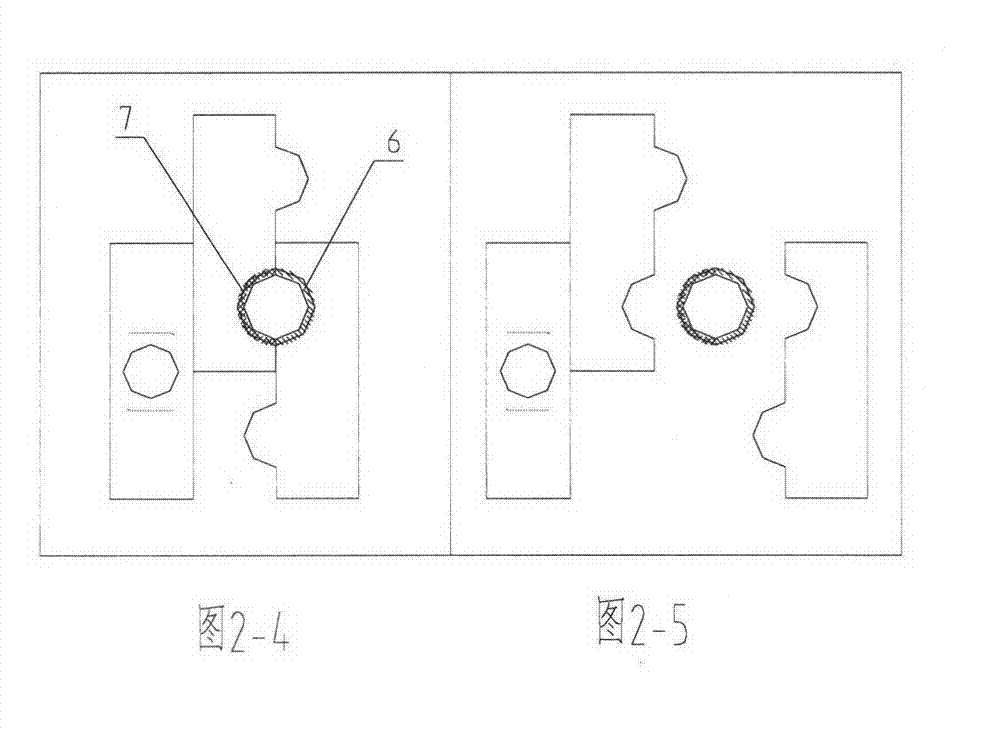

[0012] Such as figure 1 As shown, a secondary processing method for in-mold welding includes a movable mold (1), a sub-mould driving device (2), a sub-mode (3), a heating welding device (4), a fixed mold (5) and produced Half-side product (6), half-side product (7); it is characterized in that: after the movable mold (1), the sub-mould (3), and the fixed mold (5) are closed, the injection molding machine performs the injection action, and the mold is opened after the injection is completed. The movable mold (1) drives the sub-mould (3) to match the next station through the sub-mould driving device (2), and then the heating welding device (4) enters the mold area to heat half-side products (6) and half-side products (7), and then The heating welding device (4) is withdrawn, and finally the injection molding machine performs mold clamping actio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com