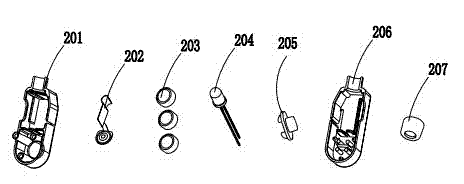

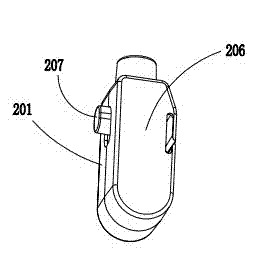

Automated assembly device of light-emitting diode (LED) finger lamps

An automatic assembly, LED lamp technology, applied in assembly machines, metal processing equipment, metal processing and other directions, can solve the problems of difficult product quality, high production costs, high labor intensity, etc., to improve production efficiency and product quality, improve Market competitiveness and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

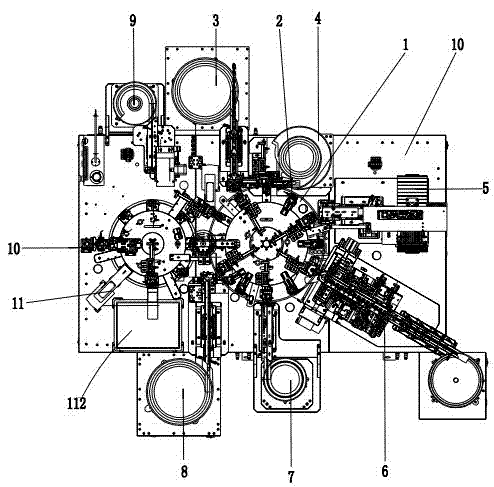

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

[0026] as attached Figure 3-9 As shown, an automatic assembly equipment for LED finger lights includes a frame and a workbench 10 arranged on the frame, a large turntable 1 is arranged on the workbench 10, and a clamp 2 for placing a bottom cover is arranged on the large turntable 1 , an upper bottom cover assembly 3, an upper sheet assembly 4, an upper battery assembly 5, an upper LED light assembly 6, an upper switch assembly 7, an upper upper cover assembly 8, an upper head ring assembly 9, and a lighting detection assembly are arranged on the outer periphery of the large turntable 1 10 and the blanking assembly 11, each of the above-mentioned assemblies is respectively connected to and controlled by the main control circuit.

[0027] Wherein, the upper bottom cover assembly 3 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com