Optional processing process of clutch driven disc

A processing technology and clutch technology, which is applied in the processing field of clutch driven plates, can solve the problems of large deformation and low production efficiency, and achieve the effects of improving life and performance, improving production efficiency, and improving product dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The manufacturing process of the clutch driven plate of the present invention has the following steps:

[0025] (1) Blanking, punching holes, punching φ10 holes, and φ12 holes: the 65Mn strip steel plate is passed through blanking, punching holes, punching φ10 holes, and φ12 holes on the punching machine, and falls out of the driven piece with a gap shape, medium hole, φ10 hole, φ12 hole shape, and

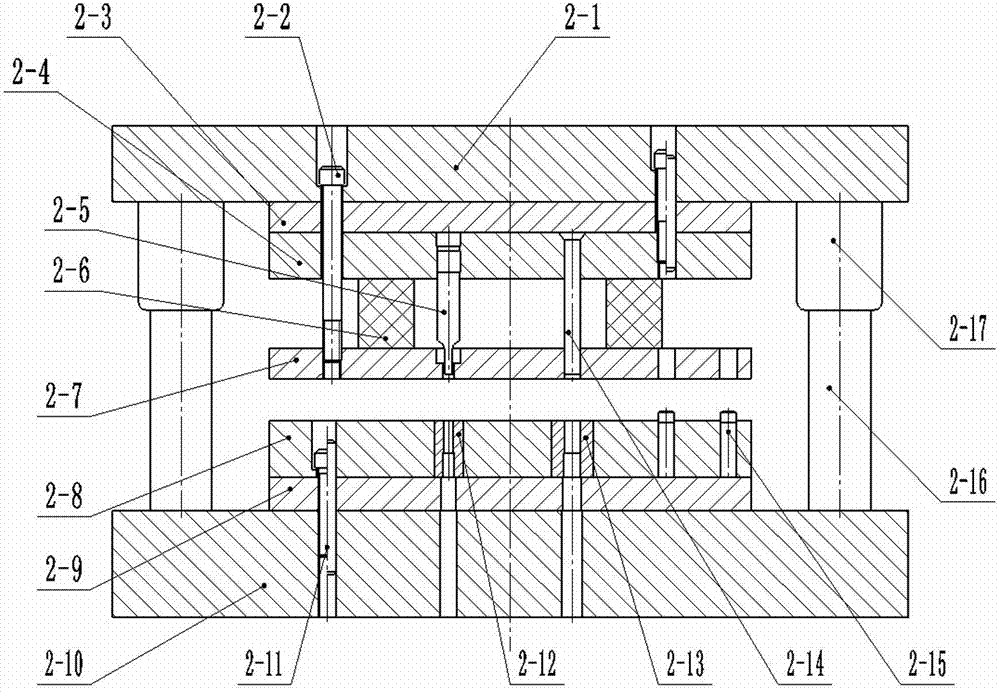

[0026] (2) Punching φ6.2 hole, φ5.2 hole, limit hole: Punch out φ6.2 hole, φ5.2 hole of driven plate through φ6.2 hole, φ5.2 hole, limit hole mold on the press machine The shape of the hole and the limit hole;

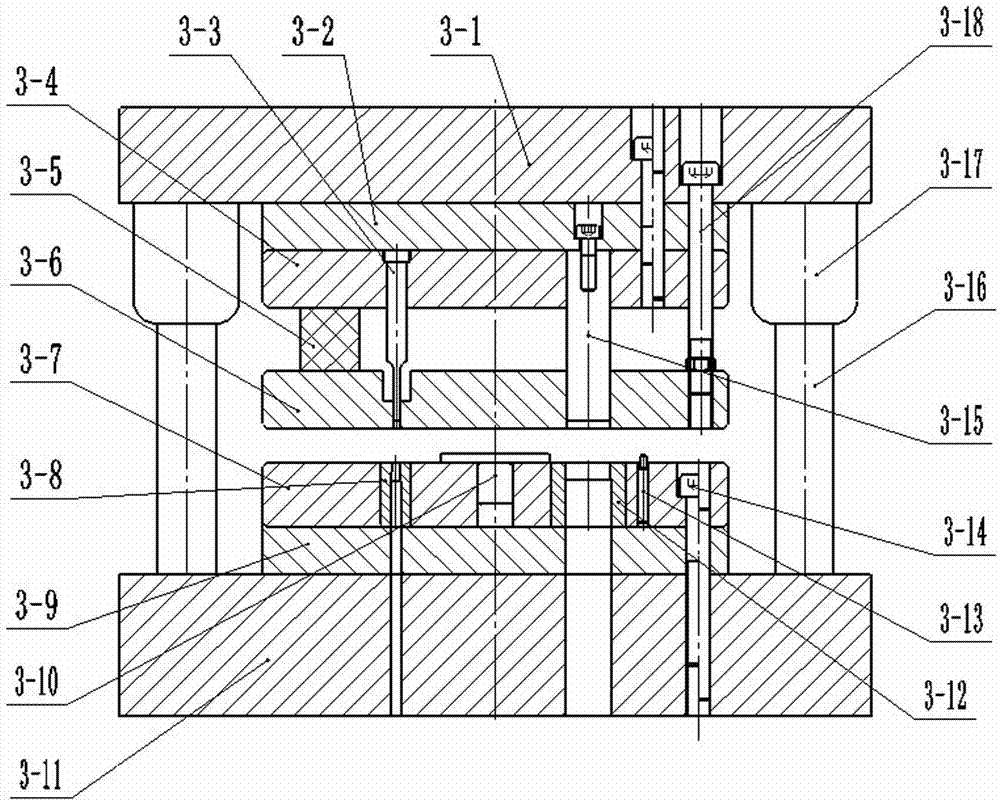

[0027] (3) Punching window and punching groove: On the punching machine, pass through the punching window and the punching groove mold to directly form a window and a long U-shaped groove.

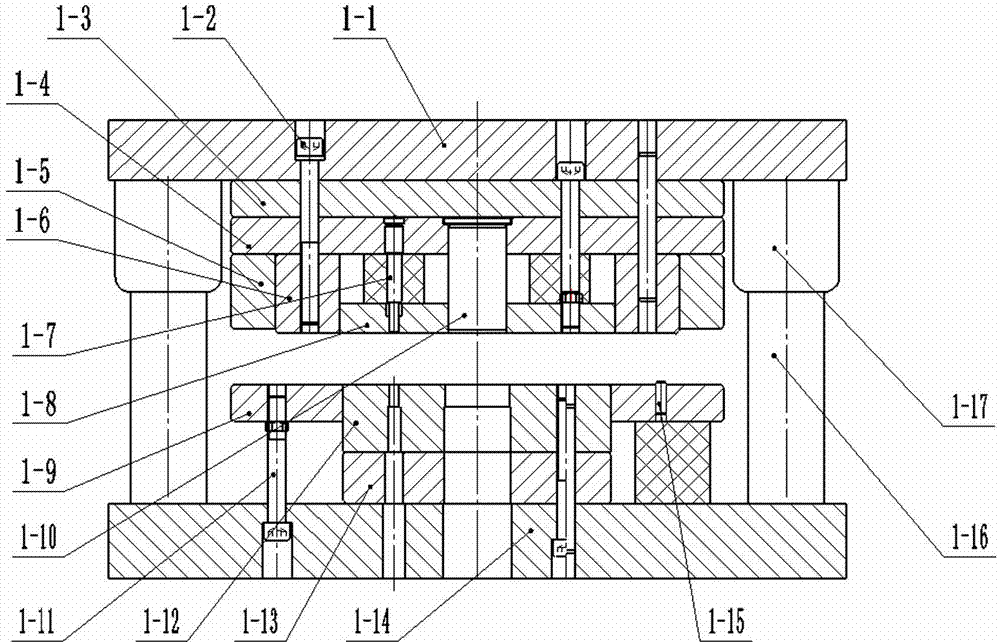

[0028] refer to figure 1 , the blanking, punching hole, punching φ10 hole, φ12 hole die consists of the first upper template 1-1, screw 1-2, first upper backing plate 1-3, pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com