Preparation process of fried bean curd

A preparation process and oily tofu technology, applied in the field of oily tofu preparation technology, can solve the problems of poor foaming, thick skin, rough taste and the like of oily tofu, and achieve the effects of fine organization, strong bean flavor and bright yellow appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

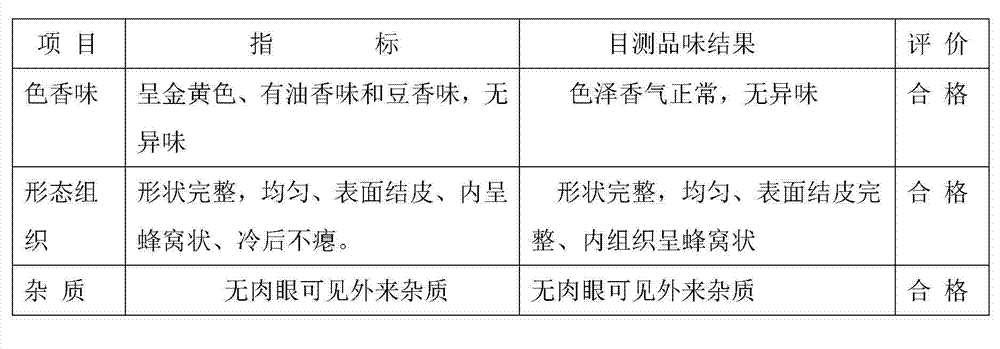

Examples

Embodiment 1

[0021] (1) Soybean screening: sift out impurities in soybeans.

[0022] (2) Soaking: Soak the soybeans treated in step (1) in water for 15 hours according to the material-to-water ratio of 1:3.

[0023] (3) Cleaning: After the soaking in step (2), drain the water in which the soybeans were soaked, and then rinse the soybeans with clean water.

[0024] (4) Refining: Refining the cleaned soybeans with water to obtain a paste.

[0025] (5) Centrifugation: Grind the paste through three cycles of high-speed centrifugation, throw out the bean dregs, and obtain soybean milk. The mesh of the centrifugal filter is 100-120 mesh, and the centrifugal speed is 1600 rpm; the soybean milk obtained by the first and second centrifugation is directly After mixing, a puree of 9-10 degrees Baume (measured by a sugar meter, representing the solid content) is obtained, and enters the pulping process; the third centrifugation is performed to obtain a raw pulp water of 1-1.5 degrees Baume (measured ...

Embodiment 2

[0034] (1) Soybean screening: sift out impurities in soybeans.

[0035] (2) Soaking: Soak the soybeans treated in step (1) in water for 8 hours according to the material-to-water ratio of 1:5.

[0036] (3) Cleaning: After the soaking in step (2), drain the water in which the soybeans were soaked, and then rinse the soybeans with clean water.

[0037] (4) Refining: Refining the cleaned soybeans with water to obtain a paste.

[0038] (5) Centrifugation: Grind the paste through three cycles of high-speed centrifugation, throw out the bean dregs, and obtain soybean milk. The mesh number of the centrifugal filter is 100-120 mesh, and the centrifugal speed is 2200 rpm; the soybean milk obtained by the first and second centrifugation is directly After mixing, a puree of 9-10 degrees Baume (measured by a sugar meter, representing the solid content) is obtained, and enters the pulping process; the third centrifugation is performed to obtain a raw pulp water of 1-1.5 degrees Baume (mea...

Embodiment 3

[0047] (1) Soybean screening: sift out impurities in soybeans.

[0048] (2) Soaking: Soak the soybeans treated in step (1) in water for 10 hours according to the material-to-water ratio of 1:4.

[0049] (3) Cleaning: After the soaking in step (2), drain the water in which the soybeans were soaked, and then rinse the soybeans with clean water.

[0050] (4) Refining: Refining the cleaned soybeans with water to obtain a paste.

[0051] (5) Centrifugation: Grind the paste through three cycles of high-speed centrifugation, throw out the bean dregs, and obtain soybean milk. The mesh of the centrifugal filter is 100-120 mesh, and the centrifugal speed is 2000 rpm; the soybean milk obtained by the first and second centrifugation is directly After mixing, a puree of 9-10 degrees Baume (measured by a sugar meter, representing the solid content) is obtained, and enters the pulping process; the third centrifugation is performed to obtain a raw pulp water of 1-1.5 degrees Baume (measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com