Oil-injecting device and oil-injecting method for cake molds

A pastry mold and oil injection device technology, applied in baking, food science, application and other directions, can solve the problems of unsatisfactory oil injection effect of oil injection machine, uneven oil injection efficiency, affecting cake quality, etc., and achieve maintenance Simple and easy to implement, simple and clear in structure, and low in manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

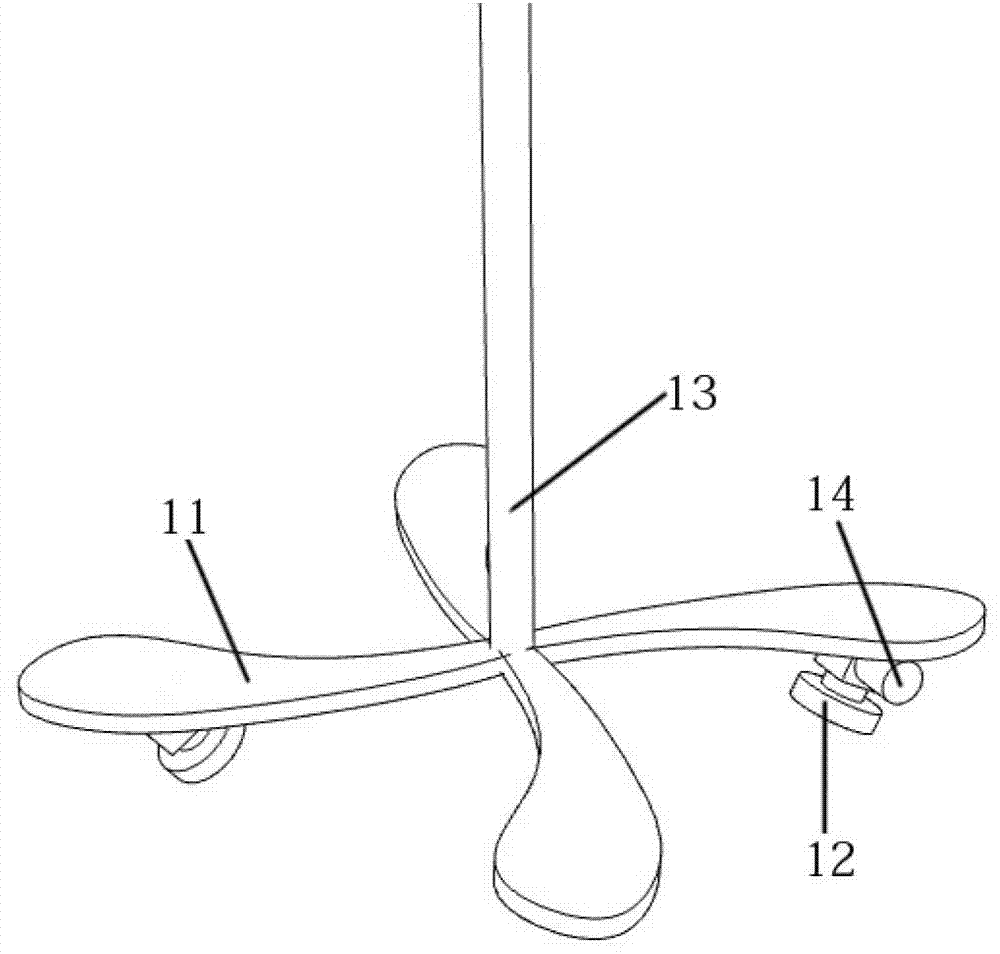

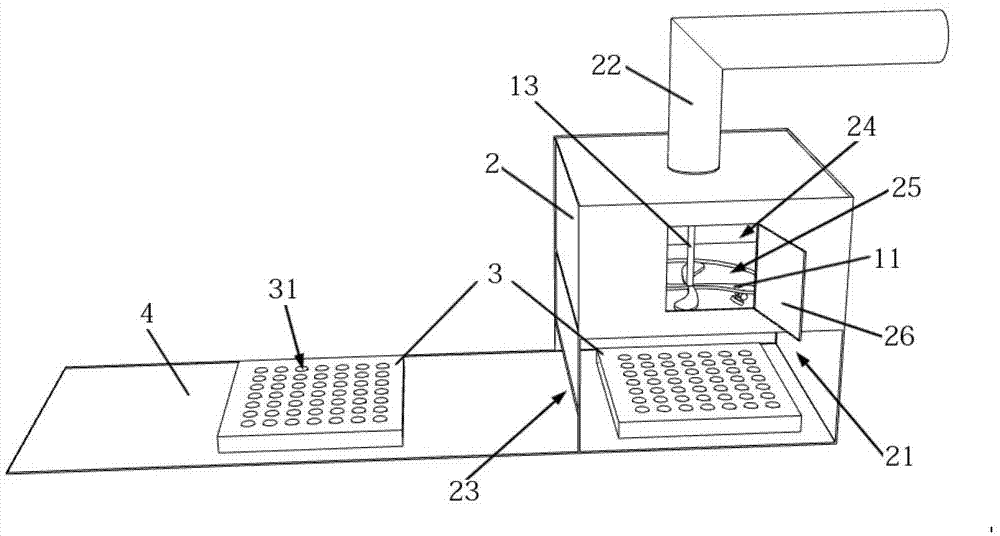

[0017] Such as figure 1 , figure 2 Shown a kind of pastry mold spraying device, comprise rotating shaft 13, be connected to the rotating piece 11 of rotating shaft 13 bottoms, be fixed on the nozzle 12 of rotating piece 11 bottoms; Described nozzle 12 quantity is more than two; Nozzle 12 is in The axis intersects at a point on the axis where the rotating shaft 13 is located; the rotating shaft 13 drives the rotating piece 11 to rotate back and forth; the intersection point of the axis where the nozzle 12 is located is higher than the plane where the pastry mold 3 to be sprayed is located.

[0018] Adopt above-mentioned arrangement, because nozzle 12 quantity is more than two, so can guarantee under the situation that rotating piece 11 rotates, spray oil as evenly as possible, simultan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com