High-altitude test clamp

A technology of testing pliers and pliers sleeves, applied in the direction of the casing of the measuring device, etc., can solve the problems of climbing wiring, broken pliers, heavy current lines, etc., and achieve the effects of high contact pressure, reliable contact, and improved working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

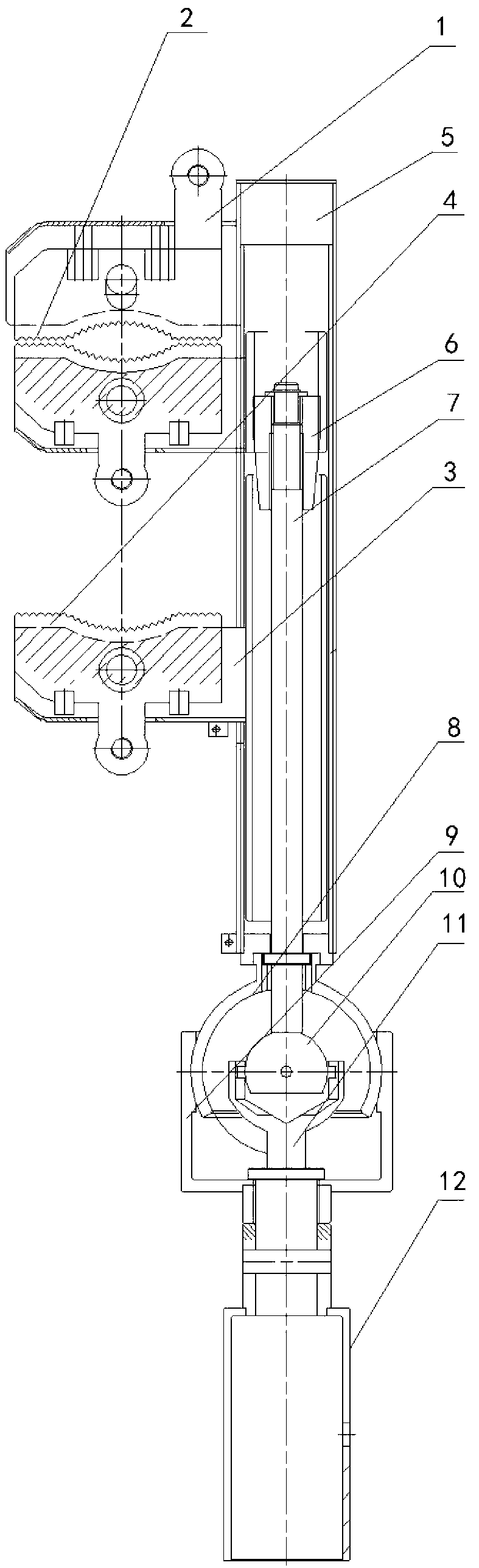

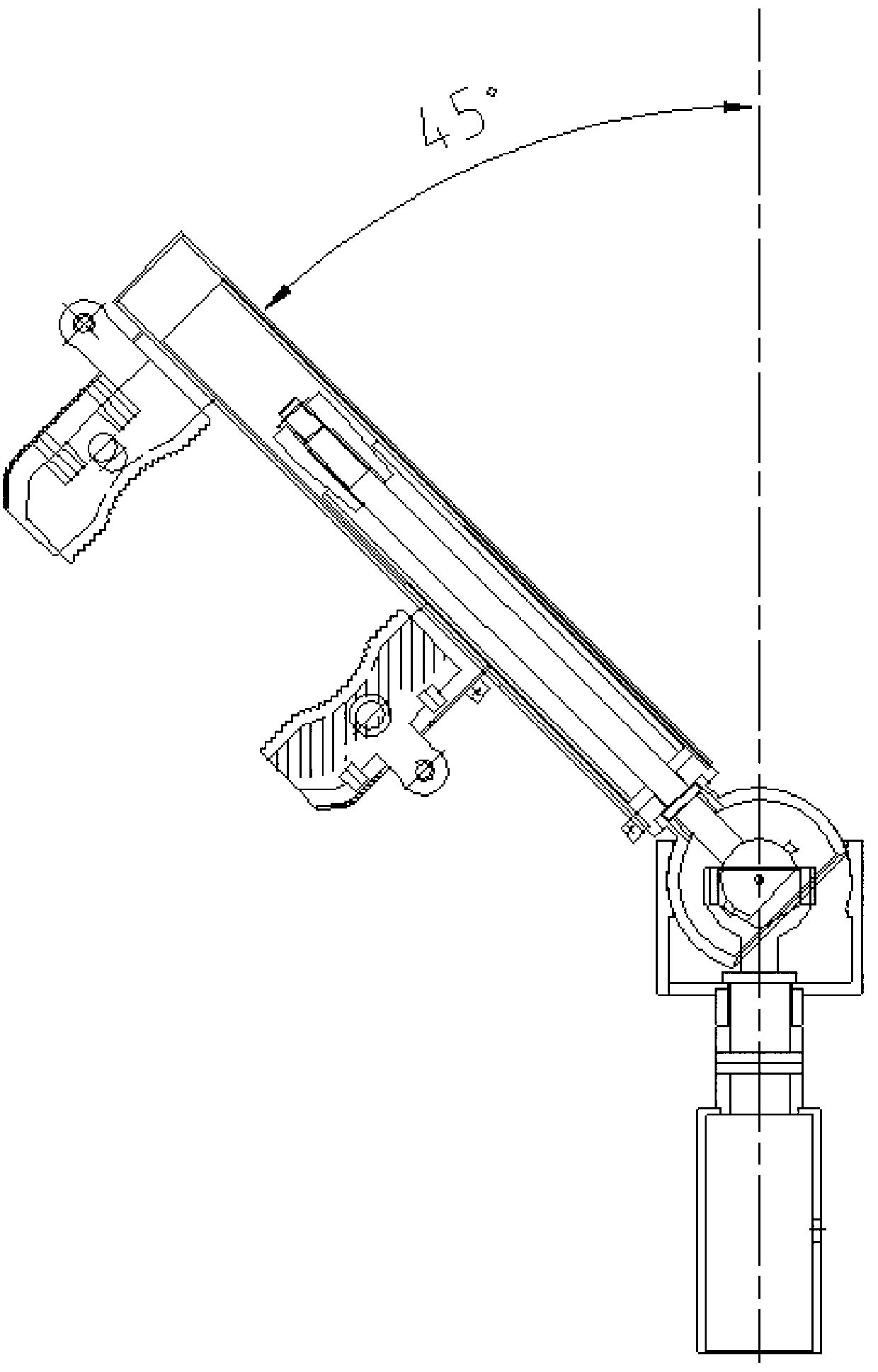

[0025] see figure 1 It can be seen that the upper jaw 2 and the lower jaw 4 are respectively fixed in the upper jaw 1 and the lower jaw 3, and the above-mentioned upper jaw 2 and the upper jaw 1, as well as the lower jaw 4 and the lower jaw 3 are all provided with There is an insulating pad to maintain insulation. The test clamp is provided with a long sliding seat 5. The inside of the sliding seat 5 is hollow and forms a chute. One side of the outer wall is provided with an opening along the chute. A screw 7 is fixed in the chute. , and the nut 6 that cooperates with the screw rod 7 and can slide along the chute constitutes the screw drive mechanism. The end of the screw rod 7 is fixed on one end of the slide seat 5 (this end is defined as the bottom end) and protrudes from this end and connects with the connecting rod 12 Connected, so that turning the connecting rod 12 can make the nut 6 move up and down along the chute, the upper clamp sleeve 1 is fixed on the other end of ...

Embodiment 2

[0031] As in the scheme of embodiment 1, when the clamping work is completed by rotating the screw 7, there will be the following problems. Because it is high-altitude clamping, in order to facilitate alignment and clamping, a larger jaw opening is required, and a larger jaw The opening needs to rotate the connecting rod 12 for a long time to complete the clamping, which makes the staff need to hold the connecting rod 12 for a long time to rotate, and the labor intensity is relatively large. Thus, on the basis of Embodiment 1 "screw drive mechanism structure-fine adjustment", a "coarse adjustment" scheme is added to form Embodiment 2 of the new technical solution.

[0032] Add an upper sliding sleeve 14 and a lower sliding sleeve 15 in the chute of the sliding seat 5, and fix the upper clamp sleeve 1 on the upper sliding sleeve 14 from the opening of the sliding seat 5, so that the upper clamp sleeve 1 can follow the upper sliding sleeve 14 moves up and down along the inner ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com