Percussive device of rotary kiln

A technology of impact device and rotary kiln, which is applied in the field of impact device, can solve the problems of unburned content of raw materials, high proportion of materials, and burnt products, so as to avoid sticking and burning, improve quality and yield, and ensure quality and the effect of the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

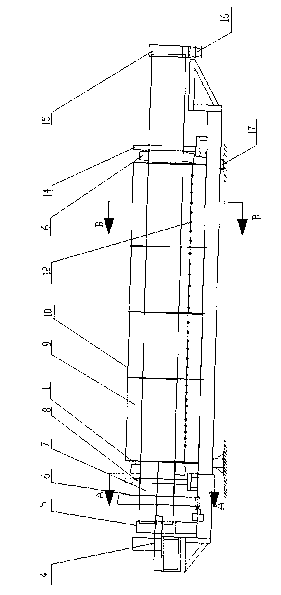

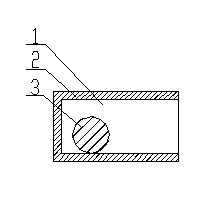

[0017] Such as Figure 2-4 As shown, a rotary kiln with a fixed impact device includes an impact device 1, a hollow cavity 2, a sphere 3, a screw feeder 4, a kiln head box 5, a driving device 6, a heating furnace cylinder 7, and a front support wheel 8 , electric heating and heat preservation furnace 9, rear support wheel 14, kiln tail box 15 and base 17, heating furnace cylinder 7 is supported by front support wheel 8, rear support wheel 14, and the front and rear ends of furnace cylinder are respectively installed in kiln head box 5 and In the kiln tail box 15, the center line of the heating furnace barrel 7 is at a certain angle to the horizontal plane, and one end of the heating furnace barrel 7 located in the kiln head box 5 is higher than the other end located in the kiln tail box 15; the drive for driving the heating furnace barrel 7 to rotate The device 6 is arranged between the kiln head box 5 and the front supporting wheel 8; the outer wall of the heating furnace cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com