Entire circular type internal recycling reverser

A technology of internal circulation and return device, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problem of large impact force, poor smoothness of S-shaped bead space trajectory, low transmission stability and low efficiency and other problems, to achieve the effect of high production efficiency, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

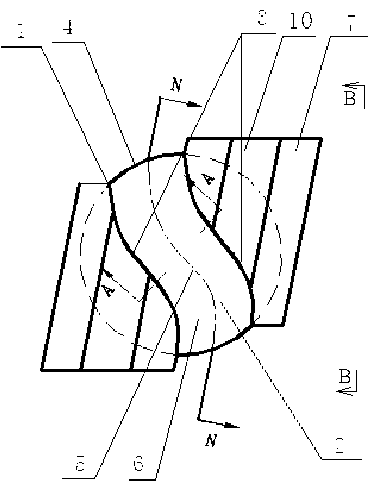

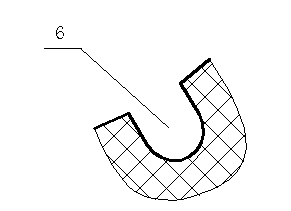

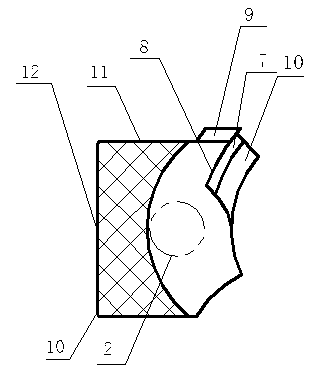

[0025] see figure 1 , figure 2 with image 3 , this overall circular internal circulation reverser includes a cylindrical reverser body 1 and an S-shaped circulation channel 2; the S-shaped circulation channel 2 is integrally formed by the cylindrical reverser body 1 being recessed inward, and the The connection between the S-shaped circulation channel 2 and the upper surface of the cylindrical reverser body 1 is the connecting line 3 of the two raceways of the nut, and the two ends of the S-shaped circulation channel 2 are the nut circulation ports 4 that match the interface of the nut raceway. ; Inside the S-shaped circulation channel 2 is an S-shaped ball-returning space trajectory 5, and the mathematical model of the space-returning bead trajectory 5 is a quintic parabola. see figure 2 , the cross section of the S-shaped circulation channel 2 in the direction perpendicular to the bead returning space trajectory 5 is a single arc cross section, forming a single arc typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com