Centrifugal fan

A centrifugal fan and shaft center technology, applied in non-variable pumps, components of pumping devices for elastic fluids, machines/engines, etc., can solve the problem of reduced air intake, affecting heat dissipation performance, and decreased air output, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, a centrifugal fan according to a preferred embodiment of the present invention will be described with reference to related drawings, in which the same components will be described with the same reference signs.

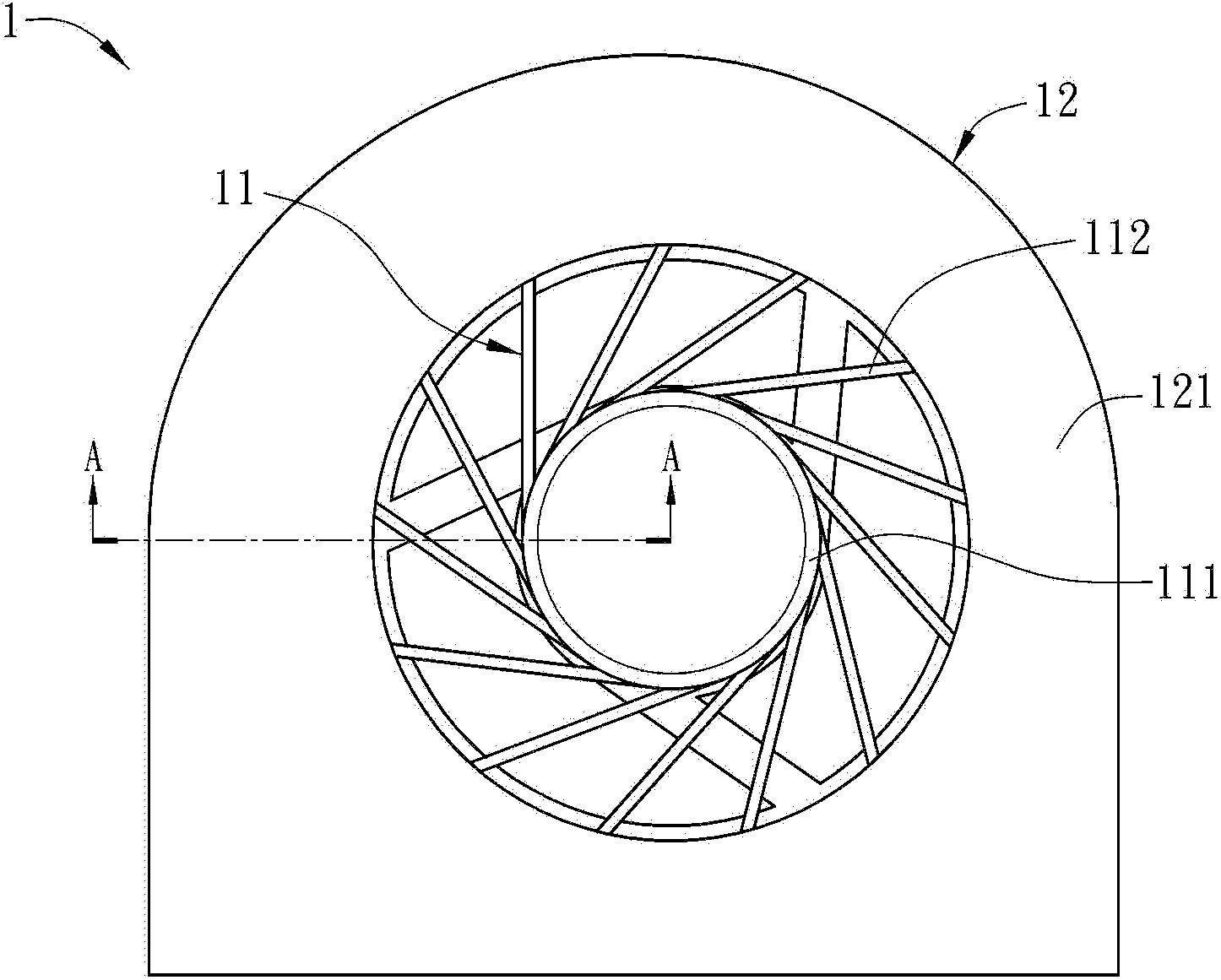

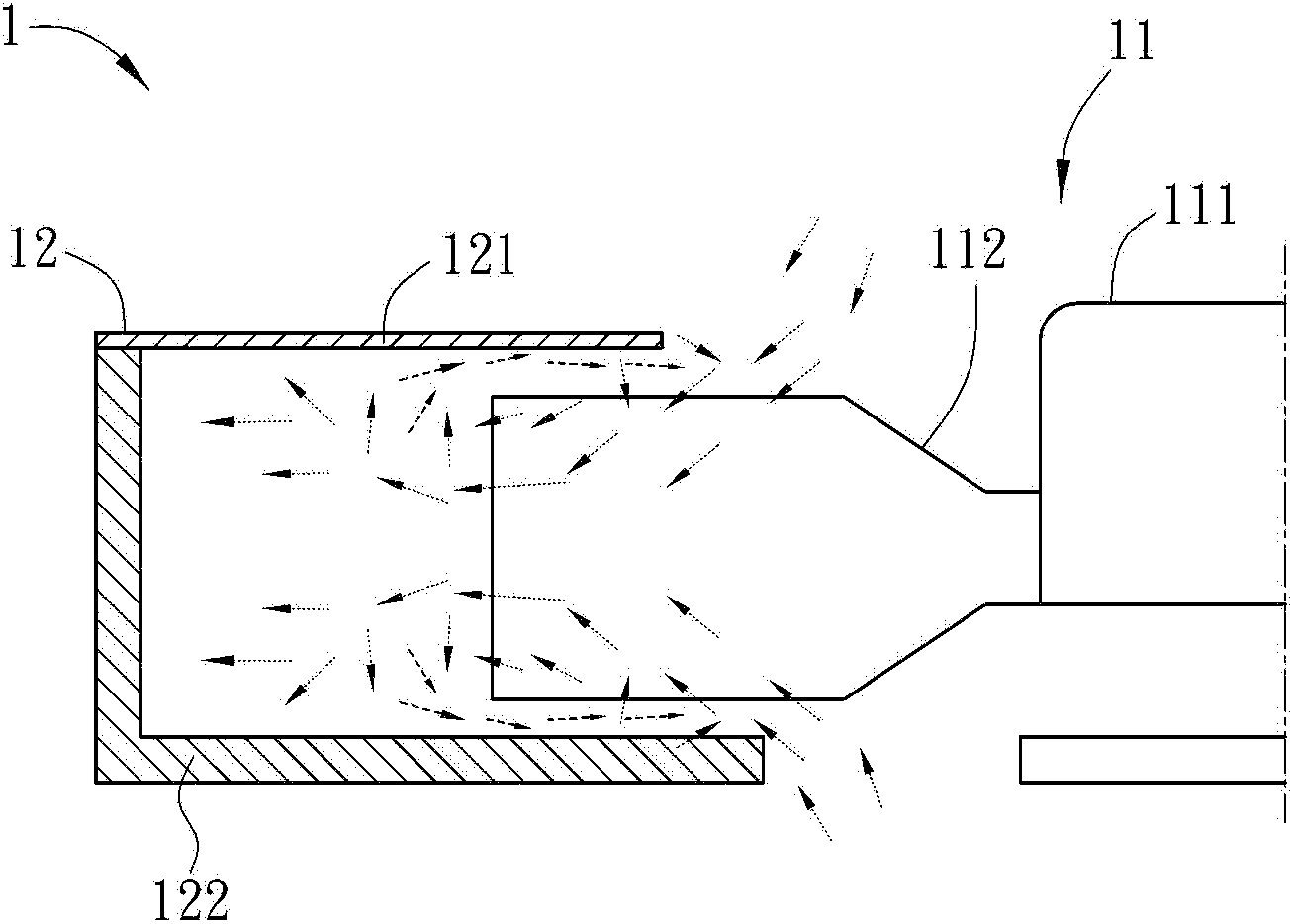

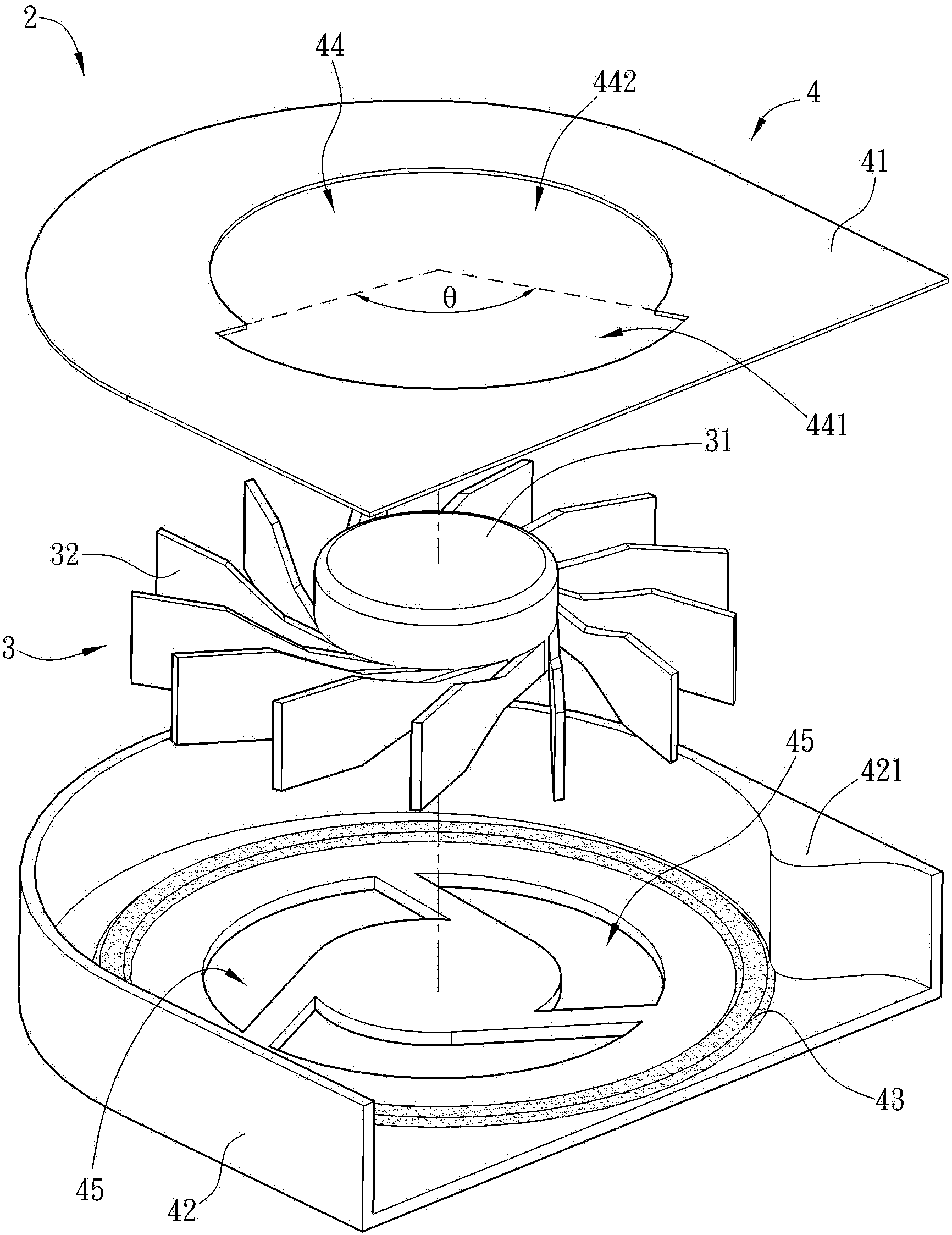

[0044] Please refer to Figure 2A to Figure 2B Shown, where Figure 2A Is an exploded schematic diagram of a centrifugal fan according to a preferred embodiment of the present invention; Figure 2B As basis Figure 2A Schematic diagram of the combined centrifugal fan. The centrifugal fan 2 includes an impeller 3 and a casing 4.

[0045] The impeller 3 has an axis 31 and a fan 32. The fan blade 32 is ringed around the shaft center 31. The impeller 3 is connected to the housing 4 with a shaft center 31.

[0046] The casing 4 covers the impeller 3. The casing 4 has an upper casing 41, a lower casing 42, at least one protrusion 43 and a first air inlet 44. The upper shell 41 and the lower shell 42 are disposed oppositely and connected to each other. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com