Two-stage hydrogenation method for producing low freezing point motor fuel

A technology of motor fuel and low freezing point, applied in the field of hydrogenation, can solve the problems of shutdown and replacement, the inability of the device to operate stably for a long period of time, and the influence of the hydrogenation catalyst operation cycle, etc., and achieve the effect of reducing the freezing point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

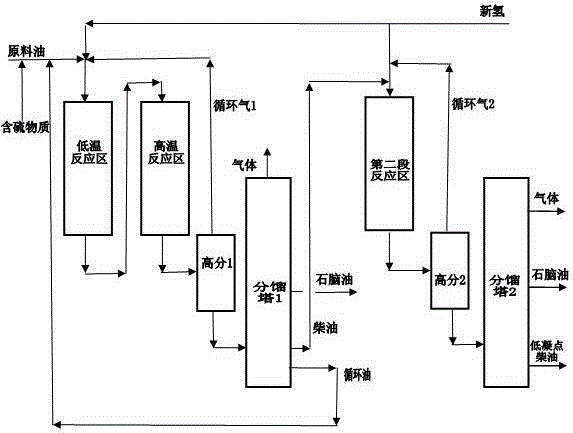

[0025] The method of the present invention is specifically as follows: using one or several mixed oils in the biogrease as the raw material oil, under the hydrogenation operation condition, the raw material oil and hydrogen pass through the low-temperature and high-temperature hydrogenation reactors filled with sulfurized catalysts to obtain The hydrogenated oil is separated in the high-pressure separator (referred to as high fraction), and the gas obtained by dehydration is recycled in the first stage of the reaction zone. The obtained liquid fractionation is mixed with hydrogen and enters the hydrogenation reformer containing isomerization performance reducing state. In the second-stage reaction zone of the catalyst, the gas obtained by separating the hydro-upgraded stream in the high-pressure separator (referred to as high fraction) is recycled in the second-stage reaction zone, and the obtained liquid is fractionally distilled to obtain the following products: gas, naphtha, O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com