Cylindrical workpiece stepped sliding chute feed device

A technology of a feeding device and a cylinder is applied in the field of a cylindrical workpiece step chute feeding device, which can solve the problems of the difficult cylindrical workpiece flowing out in the lateral state, and the inability to solve the problems of the cylindrical workpiece and single feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

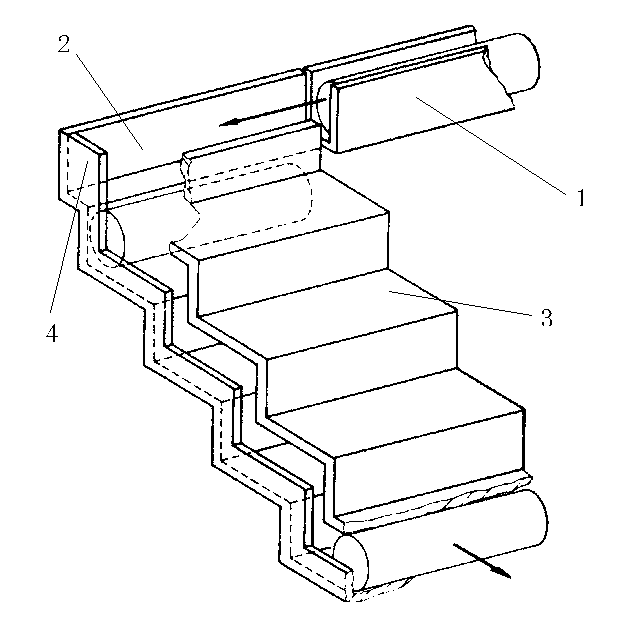

[0010] Such as figure 1 The present invention relates to a cylindrical workpiece step chute feeding device. In order to solve the above technical problems, the present invention provides the following technical solutions: a cylindrical workpiece step chute feeding device, including a feeding conveying device and an output device, feeding The conveying device is a laterally arranged feeding chute 1; the output device includes a stepped slide 2 and a step cover 3 located on the stepped slide 2. The shape of the stepped slide 2 and the shape of the stepped cover 3 are matched with each other, and the two are formed A stepped cavity, the size of the cavity is the same as the size of the workpiece; the bottom surface of the feeding chute 1 and the first step surface of the stepped chute 2 are located on the same plane and they are close to each other. A baffle 4 perpendicular to the step surface of the step slide 2 is provided on the side of the step slide 2 opposite to the feed chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com