Automated assembly method of microswitch shrapnel and carrying-out device thereof

A micro-switch, automatic assembly technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, enterprise loss, failure, etc., and achieve the effect of excellent long life and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

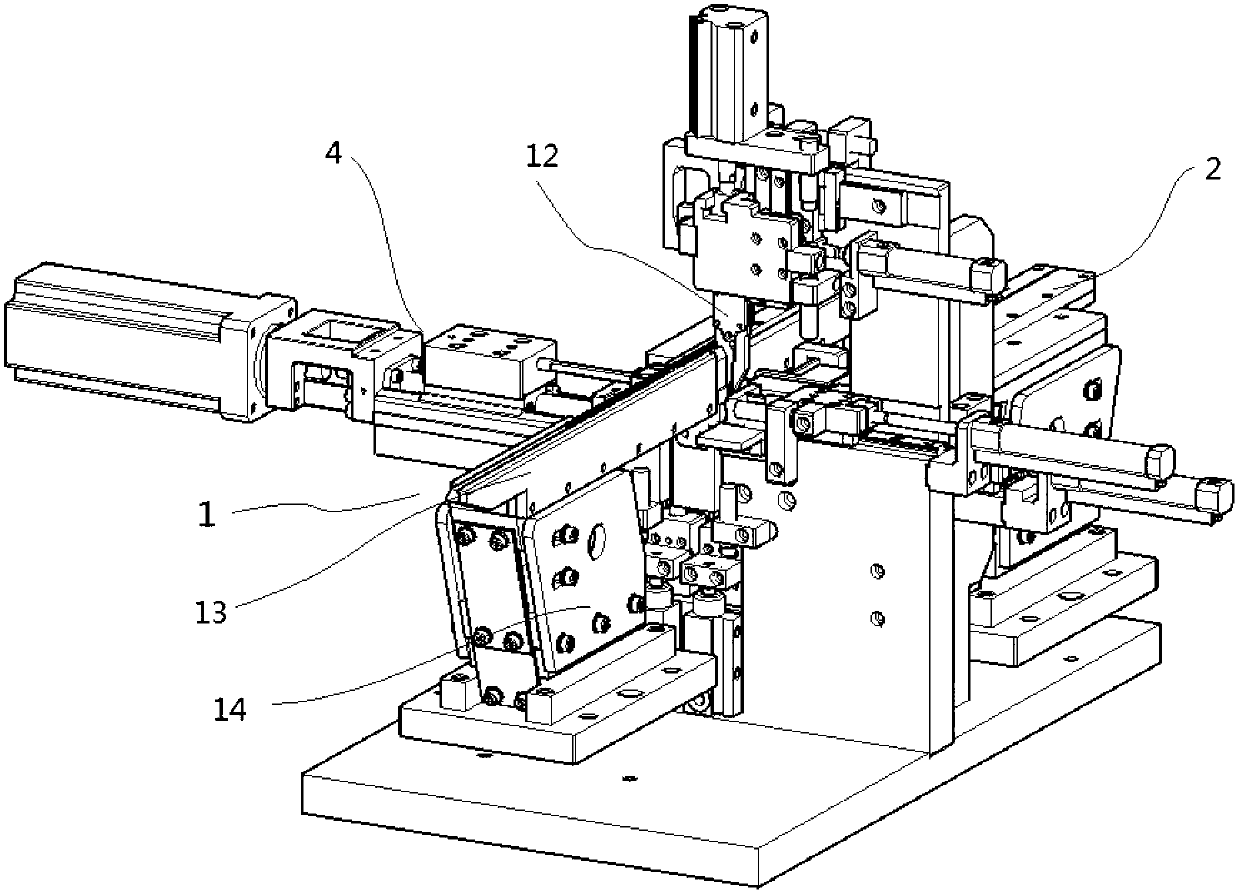

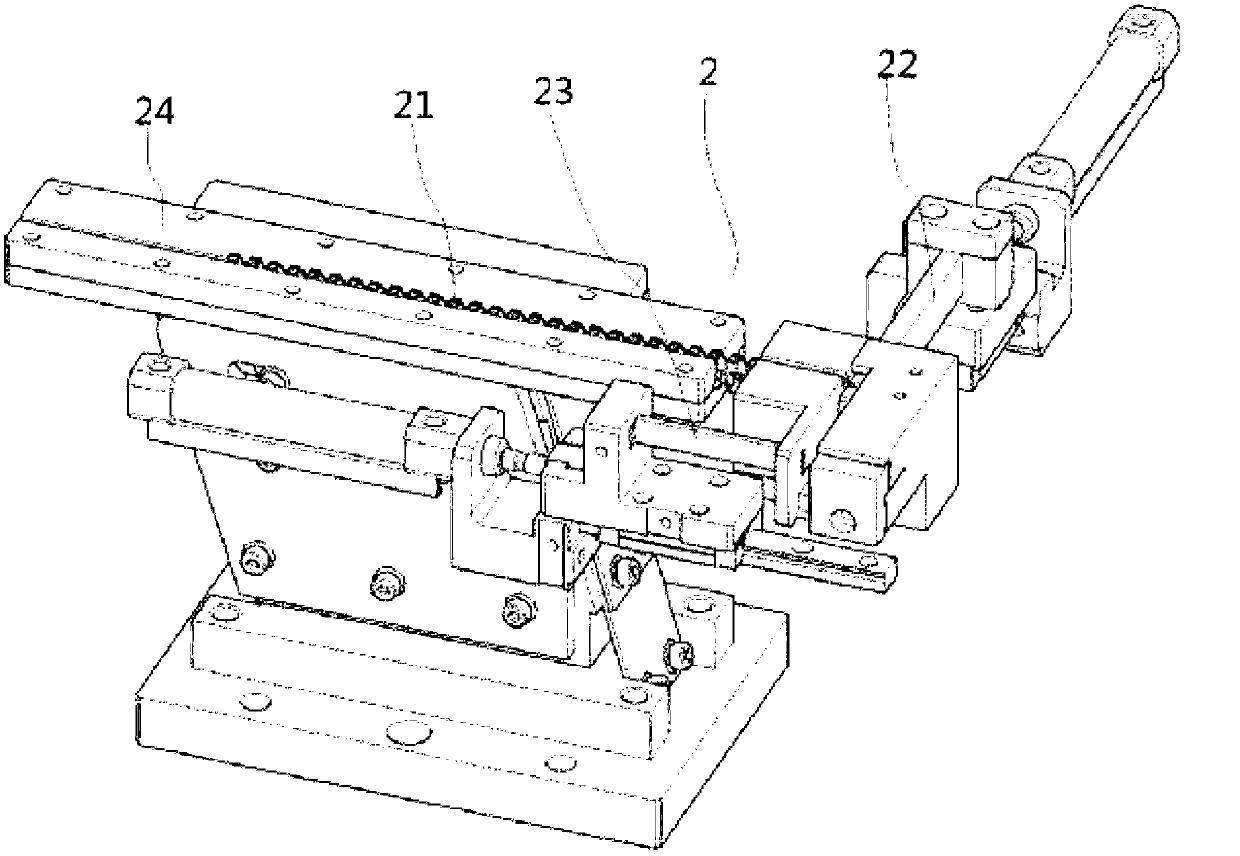

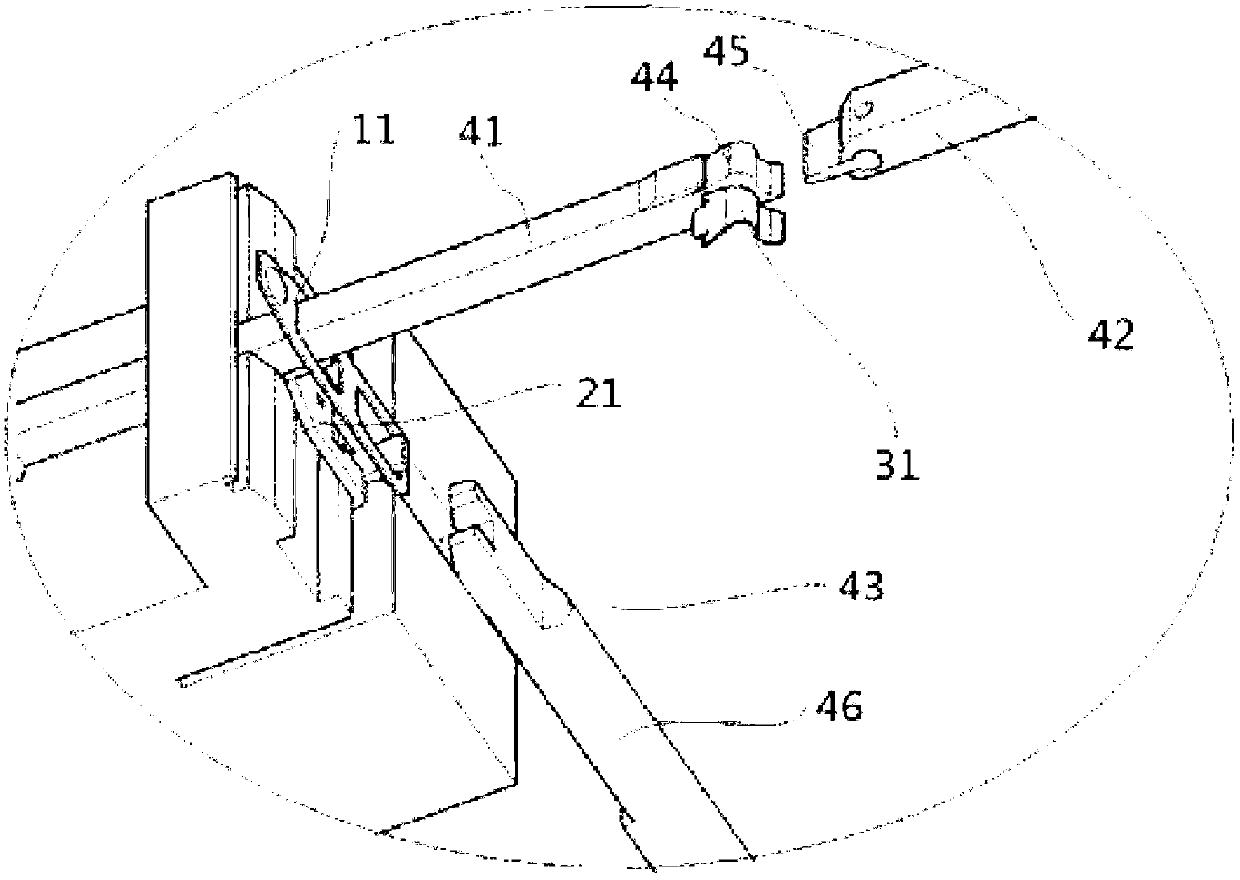

[0049] Examples, see Figure 1 to Figure 10 , the automatic assembly method of the micro switch shrapnel provided by the present invention, it comprises the following steps:

[0050] (1) Prepare materials, prepare the C pin 21 of the micro switch shrapnel, the shrapnel 11 and the bridge 31;

[0051] (2) A micro switch shrapnel automatic assembly device is set, which device includes shrapnel feeding mechanism 1, C-leg feeding mechanism 2, bridging feeding mechanism 3 and shrapnel assembly mechanism 4, and the C-leg feeding mechanism 2 includes a first push rod 22 and The second push rod 23, the shrapnel feeding mechanism 1 includes a clamping manipulator 12 and a shrapnel feeding channel 13, the clamping manipulator 12 is located above the shrapnel assembly mechanism 4, and the shrapnel feeding channel 13 pushes the shrapnel 11 in a vertical direction. Or arranged in an inclined direction and transport the shrapnel 11 to the below of the clamping manipulator 12 in the horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com