Machine for producing a paper web, in particular a sack paper web

A paper width and machine technology, which is applied in the field of machines for bag paper width, can solve problems such as poor filling characteristics, and achieve the effects of improving ductility, lowering repair and maintenance costs, and reducing tensile force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

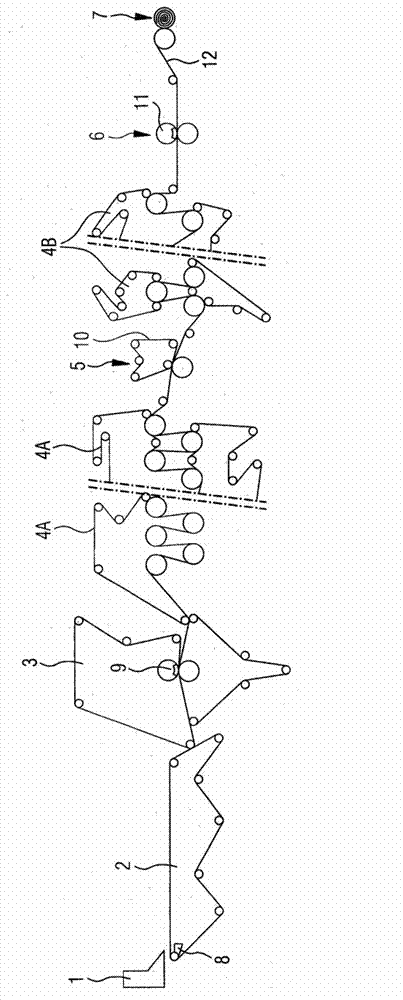

[0022] in figure 1 Shown in is a machine used to make single-layer bag paper. Through the headbox 1, the material suspension is evenly distributed across the width of the forming wire. The net part 2 is designed here as a long net part, that is, the suspension is only dehydrated downward through the forming net. As an alternative, double wire formers are also possible, in which the suspension is applied between two forming wires and dewatered towards both sides (upper and lower). The shown mesh part is equipped with a vibrating screen device 8 which makes the screen move back and forth quickly in the transverse direction. This positively influences fiber orientation and paper formation and achieves higher strength in the paper web. The press section 3 has only one shoe press nip composed of a pair of rollers and a shoe press roll 9. In the embodiment shown, the shoe press roll 9 is above and the counter roll is below. The shoe press nip is double-laid with felts (befilzen)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com