Applications of polyethylene composites doped with carbon nanotubes and nanotantalum for space charged particle radiation protection

A carbon nanotube and charged particle technology is applied in the application field of polyethylene composite materials doped with carbon nanotubes and nano tantalum for radiation protection of space charged particles, and can solve the problem of high density of aluminum protective layer, poor thermal stability, The use of large weight and other problems can achieve the effect of solving the problem of large weight, improving proton protection efficiency, and improving thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

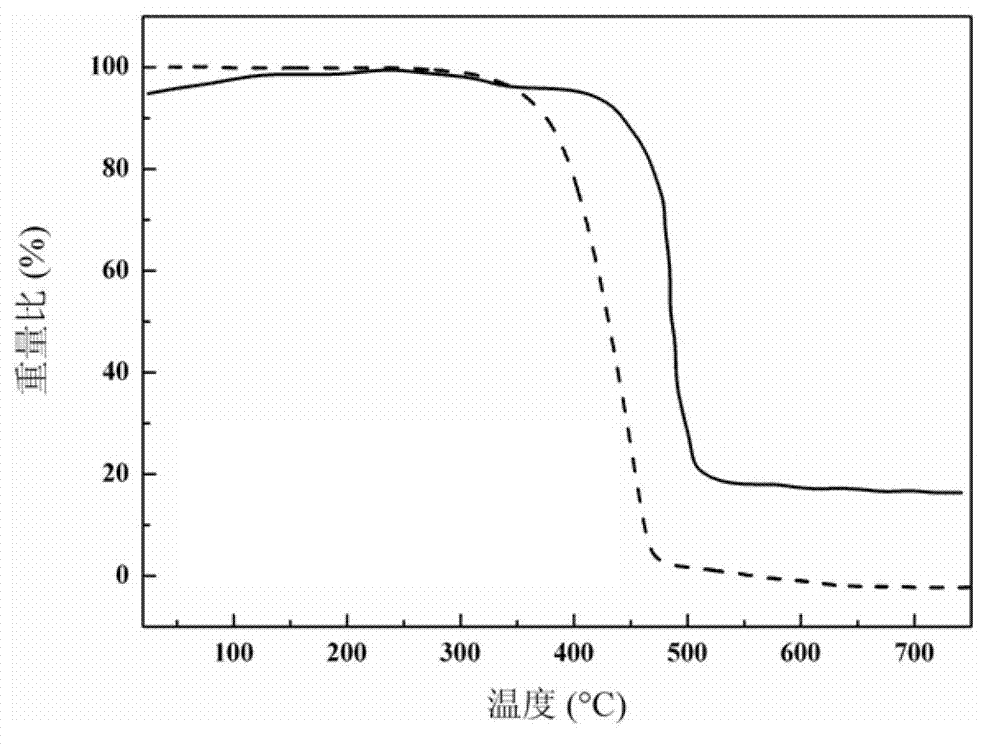

[0025] Specific embodiment 1: This embodiment is a polyethylene composite material doped with carbon nanotubes and nano-tantalum for space charged particle radiation protection, which is composed of 1 part to 100 parts of polyethylene resin, 1 part to 100 parts by weight, and 1 part to 100 parts by weight. It is prepared by 10 parts of carbon nanotubes, 5-50 parts of nano-tantalum and 0.5-20 parts of coupling agent.

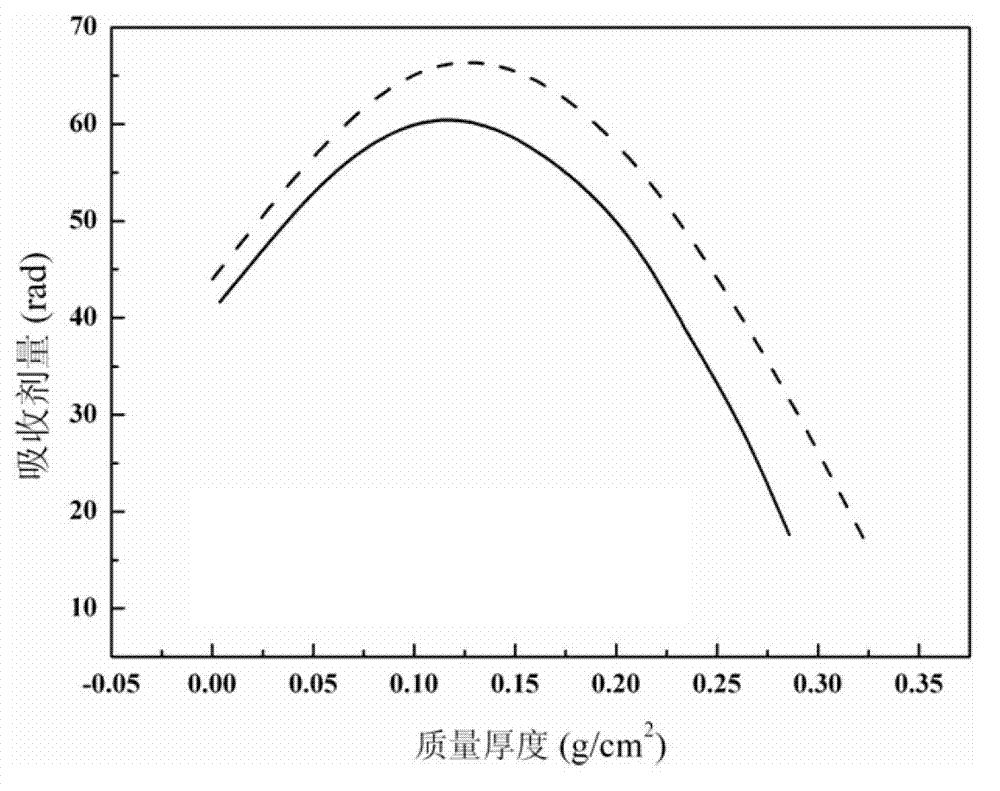

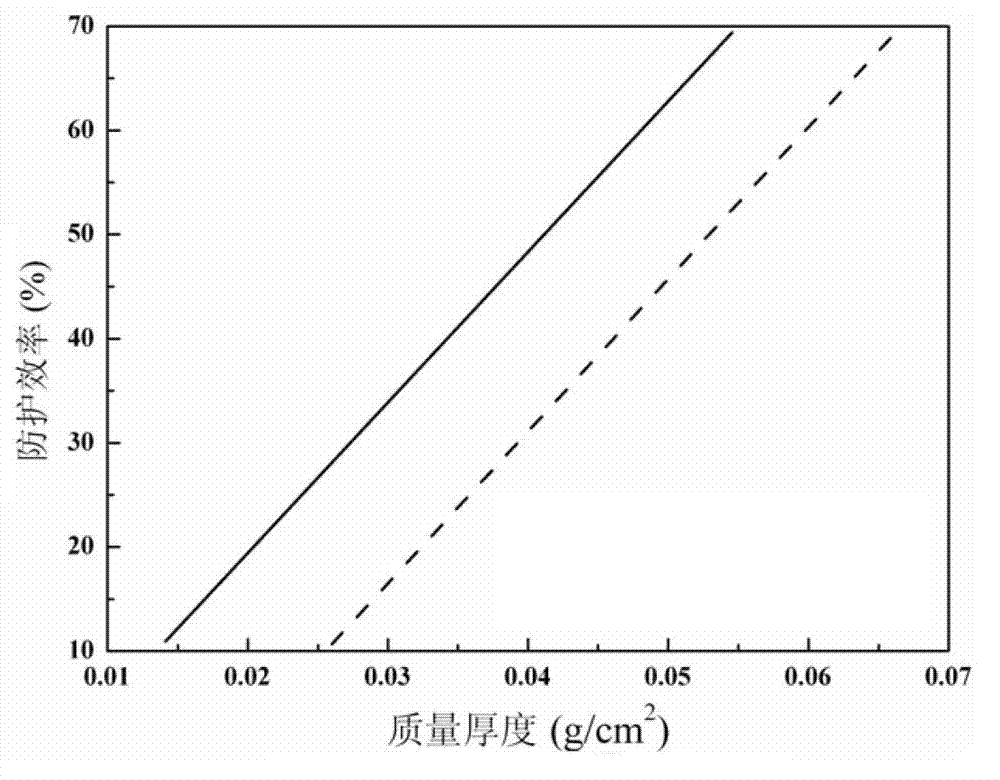

[0026] Carbon nanotubes are added to the polyethylene composite material doped with carbon nanotubes and nano tantalum for space charged particle radiation protection in this embodiment, which can better prevent polyethylene cracking and improve the proton protection effect of the material. At the same time, tantalum is added to the polyethylene composite material. Due to the high density of tantalum, when electrons are incident on the material, they are prone to large scattering, which increases the energy loss of electrons in the material and improves the electr...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the composite material is composed of 20 to 95 parts of polyethylene resin, 4 to 6 parts of carbon nanotubes, 5 parts by weight. It is prepared by 1-40 parts of nanometer tantalum and 1-15 parts of coupling agent. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the density of the polyethylene resin is 0.900 g / cm 3 ~0.980g / cm 3 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com