Motorcycle clutch centering sliding sleeve

A clutch and motorcycle technology, applied in clutches, mechanical drive clutches, springs/shock absorbers, etc., can solve the problem of small contact area between centering sleeve and driving gear casing, complex centering sliding sleeve assembly, impact sound and abnormal noise Large and other problems, to achieve the effect of easy and simple assembly, long service life, elimination of impact sound and abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

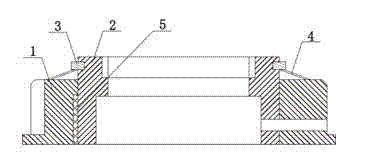

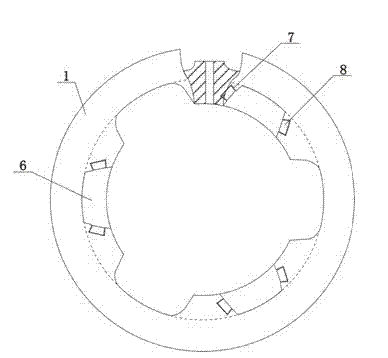

[0015] see figure 1 and figure 2 , the motorcycle clutch centering sliding sleeve of the present invention comprises a centering sleeve 1 and a driving gear overcoat 2, a chute 6 is opened on the bottom surface of the centering sleeve 1, and an annular Groove, the annular groove is provided with a circlip 3, the circlip 3 is provided with an axial corrugated damping spring 4, the inner surface of the lower part of the centering sleeve 1 is provided with a damping pad 5, and the rising of the chute 6 There is a dovetail groove 7 at the end, and a rubber pad 8 is arranged in the dovetail groove 7. The shock absorbing pad 5 is made of rubber. 8. The shape of the rubber pad 8 is the same as that of the dovetail groove 7 .

[0016] When assembling, put the driving gear jacket 2 into the centering sleeve 1 first, then put the shock absorber 5 into the lower part of the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com