Turbine type gas compressor front end dust remover and filter element thereof

A gas compressor and filter element technology, applied in pump elements, machines/engines, liquid fuel engines, etc., can solve the problems of dust ingress, filter performance of filter cartridges/bags, and service life not reaching the service life. Filtration accuracy, fouling improvement, strong rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

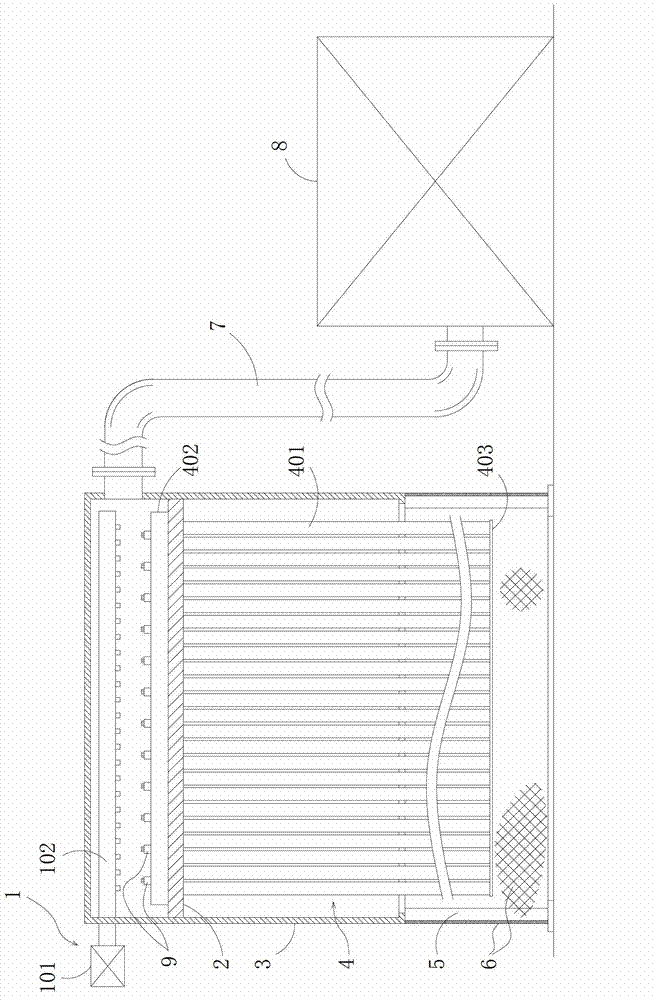

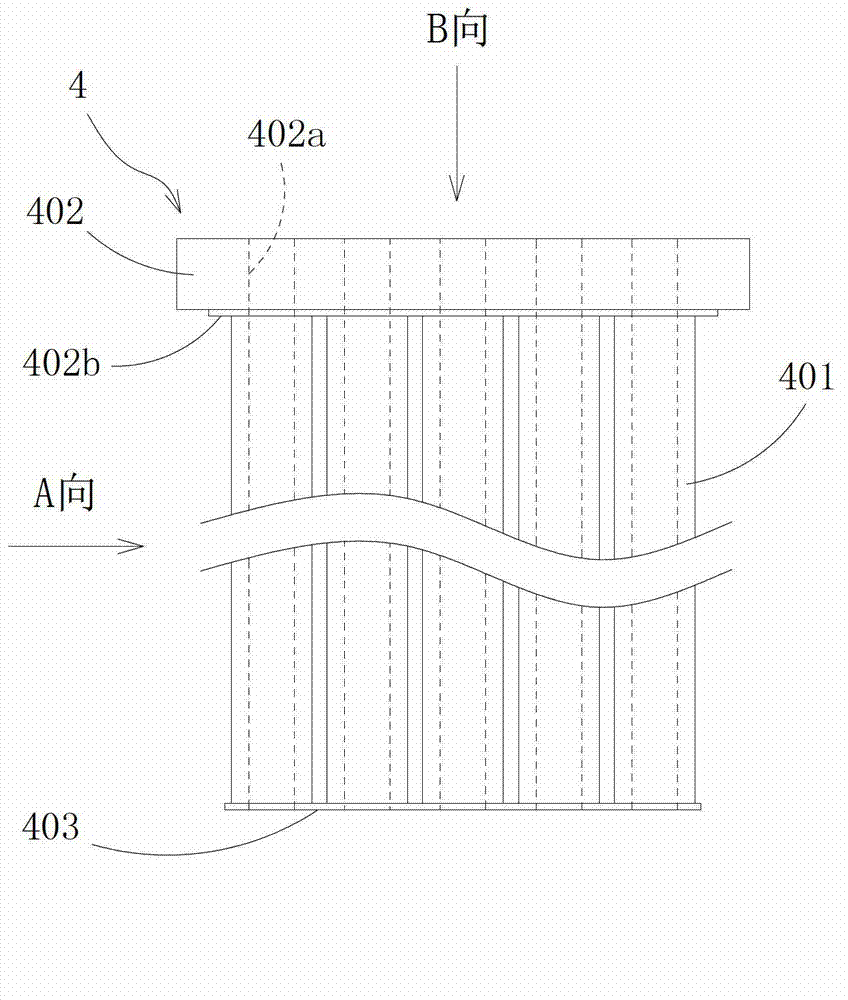

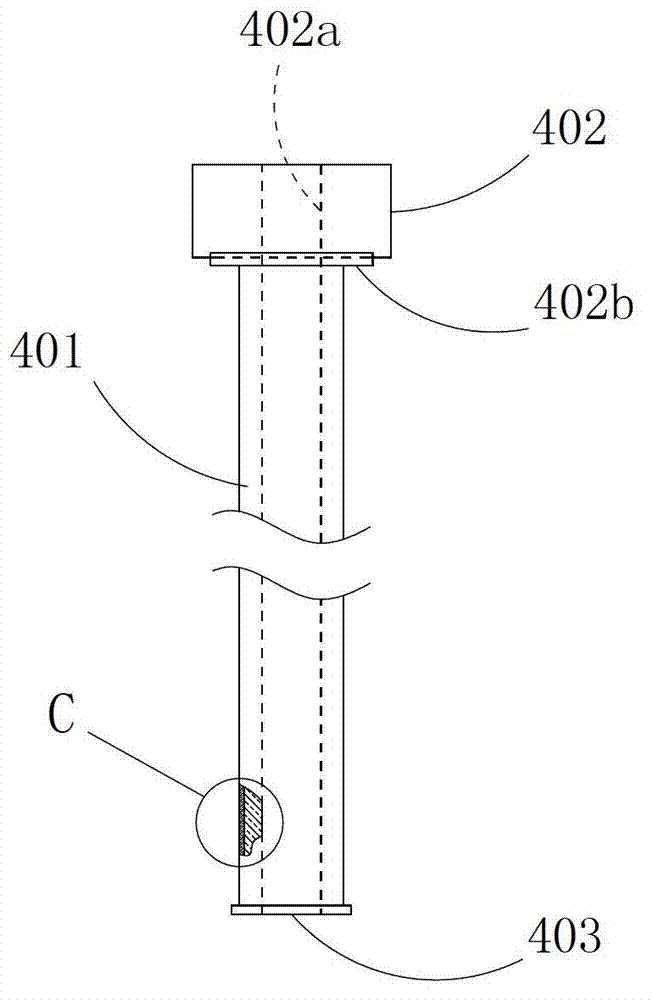

[0029] Such as Figures 1 to 5 As shown, before the turbo type gas compressor 8, a front-end dust collector is provided, and the front-end dust collector includes a casing 3, a filter element 4 installed on the casing 3, and a back-blowing and dust-cleaning device 1 acting on the filter element 4. The casing 3 and the filter element 4 are connected through the orifice plate 2 and form a separated first space and a second space. The transmission of the gas to be filtered occurs in the first space, and the transmission of the filtered gas occurs in the second space. The filter element 4 There is a filter material made of a porous high-density polyethylene support body 401b and an expanded polytetrafluoroethylene filter film 401a closely attached to the surface of the porous high-density polyethylene support body 401b; the expanded polytetrafluoroethylene filter film 401a The removal rate of dust with a particle size ≥ 0.5 μm in the gas to be filtered is above 99%. Because the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com