Transverse stiffness-reinforced rail fastener

A technology of lateral stiffness and track fasteners, which is applied in the field of rail transit, can solve the problems of reducing vertical stiffness, lateral stiffness and deflection stiffness of fasteners, low vibration and noise reduction effects, and insufficient vertical stiffness, which cannot fully meet the use requirements. Achieve the effect of suppressing the phenomenon of deflection shimmy, high fatigue life, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

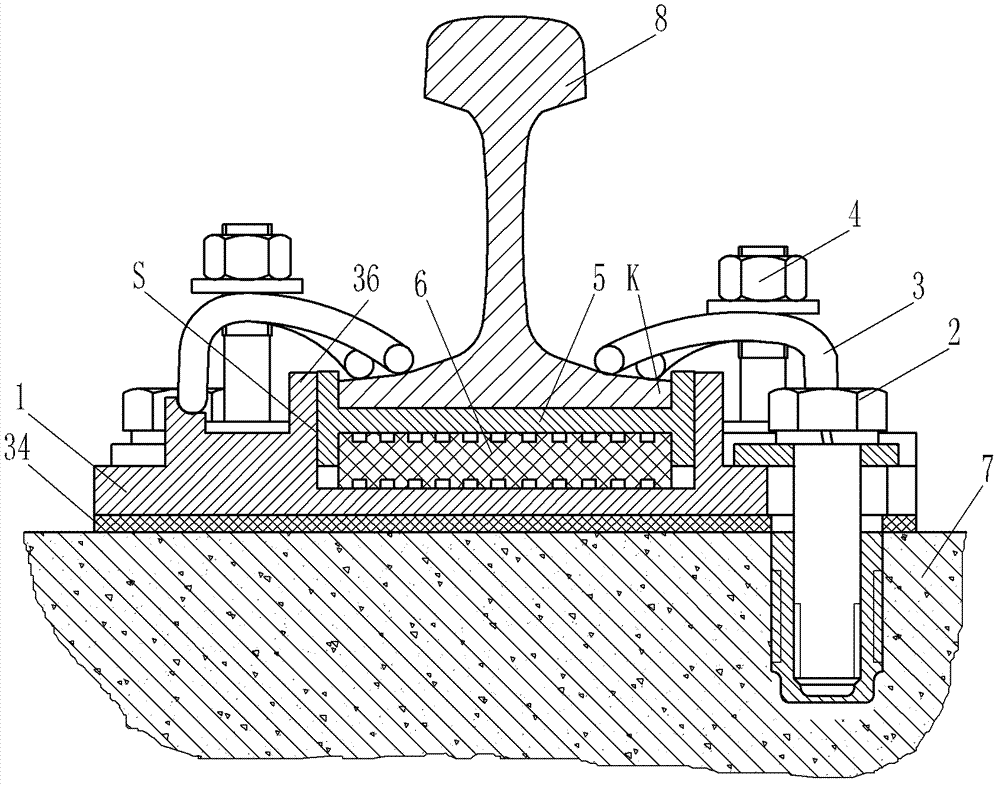

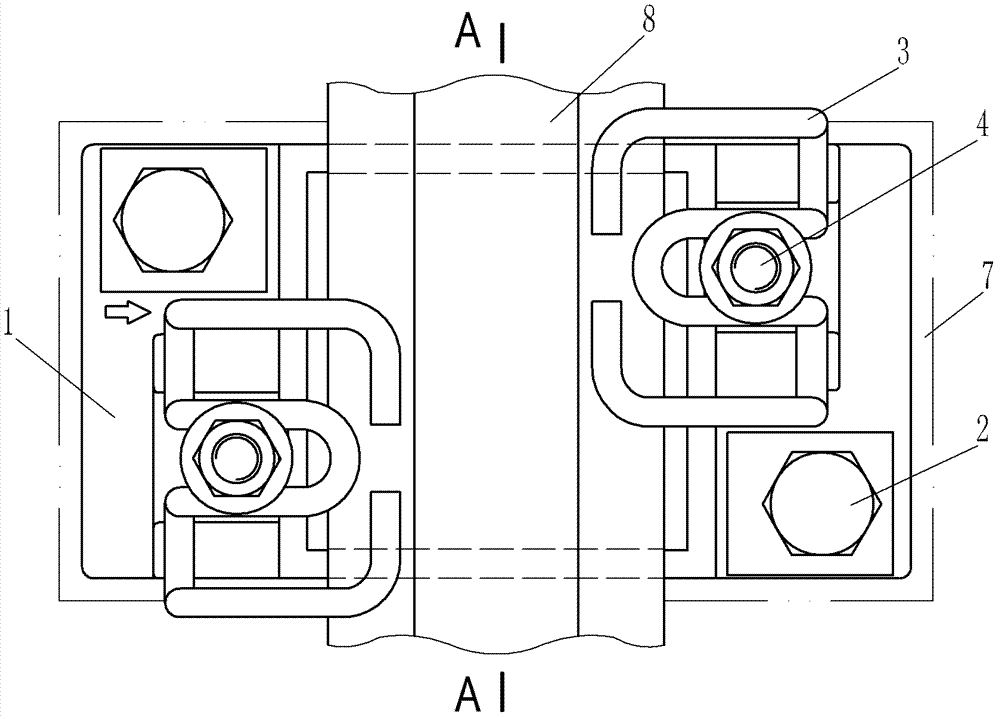

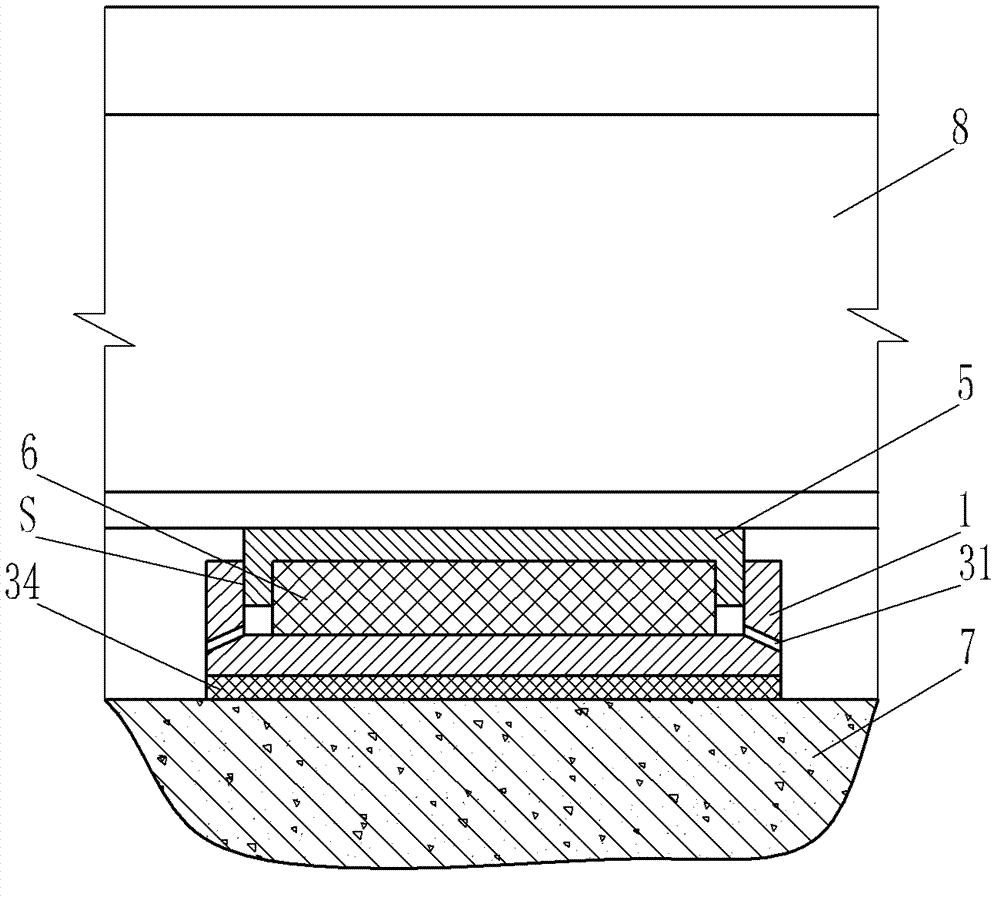

[0045] Such as figure 1 , figure 2 and image 3 The lateral rigidity reinforced rail fastener of the present invention as shown includes a base 1, an anchor bolt 2, a buckle elastic bar 3 and an elastic supporting member 6, and is characterized in that it also includes a guide 5, which is arranged between the base 1 and the rail 8 Between them, the guide piece 5 and the base 1 are made of wear-resistant cast steel material. On the base 1, corresponding to both sides of the rail 8, there are bosses 36 that protrude vertically upward along the rail. The inner vertical wall of the boss 36 and the guide piece 5. The mutually mating surfaces form a guide surface S, and the guide surfaces S are vertically arranged parallel to the track. The elastic support member 6 is arranged between the base 1 and the guide member 5, specifically elastic rubber pads with convex and concave structures on the upper and lower surfaces. During application, an elastic backing plate 34 made of rubber...

Embodiment 2

[0054] Such as Figure 4 , Figure 5 The difference between the lateral rigidity reinforced rail fastener of the present invention and the first embodiment is that the crimping elastic strip 3 in the lateral rigidity reinforced rail fastener of the present invention can also use e-shaped structure crimping elastic clips, and the crimping elastic clips 3 can be directly inserted and fixed on the guide 5. The base 1 is provided with a rail bottom slope of 1:40. In order to facilitate the adjustment of the rail spacing, a gauge member 10 is provided between the rail 8 and the guide member 5 , and the buckle spring 3 is pressed on the gauge member 10 , thereby pressing the rail 8 tightly on the guide member 5 . In addition, an elastic damping pad 9 is also added between the rail 8 and the guide 5. The elastic damping pad 9 is made of an insulating elastic rubber material. High-frequency stress wave can play a certain buffering and vibration-reducing effect, and on the other hand,...

Embodiment 3

[0061] Such as Figure 6 , Figure 7 The difference between the lateral rigidity-enhanced track fastener of the present invention and the second embodiment is that the rail bottom slope of 1:40 is set on the guide member 5. Since the rail bottom slope is set on the guide member, the lateral stiffness-enhanced type rail fastener of the present invention The longitudinal, vertical and transverse directions of the track fastener are based on the base, corresponding to the longitudinal, vertical and transverse directions of the base. The longitudinal direction of the base is equal to the longitudinal direction of the rail. The direction perpendicular to the longitudinal direction of the rail and parallel to the bottom surface of the base. In order to prolong the service life of the product and prevent excessive wear and tear when the guide 5 slides relative to the base 1 during the working process, a surface reinforcement element 12 is pasted on the guide surface of the base 1. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com