Lifting device

A hoisting device and hoisting rope technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of the hoisting device, such as large size, high manufacturing cost, cumbersome and complicated structure, etc., and achieve light weight, beautiful appearance and structure Simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

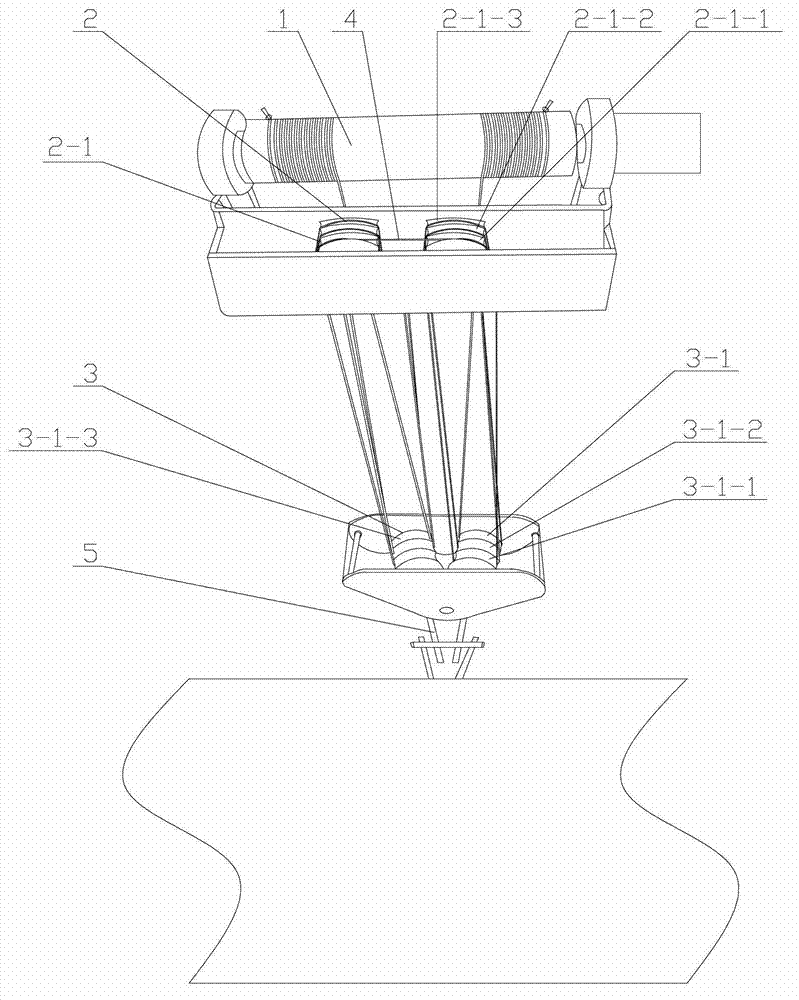

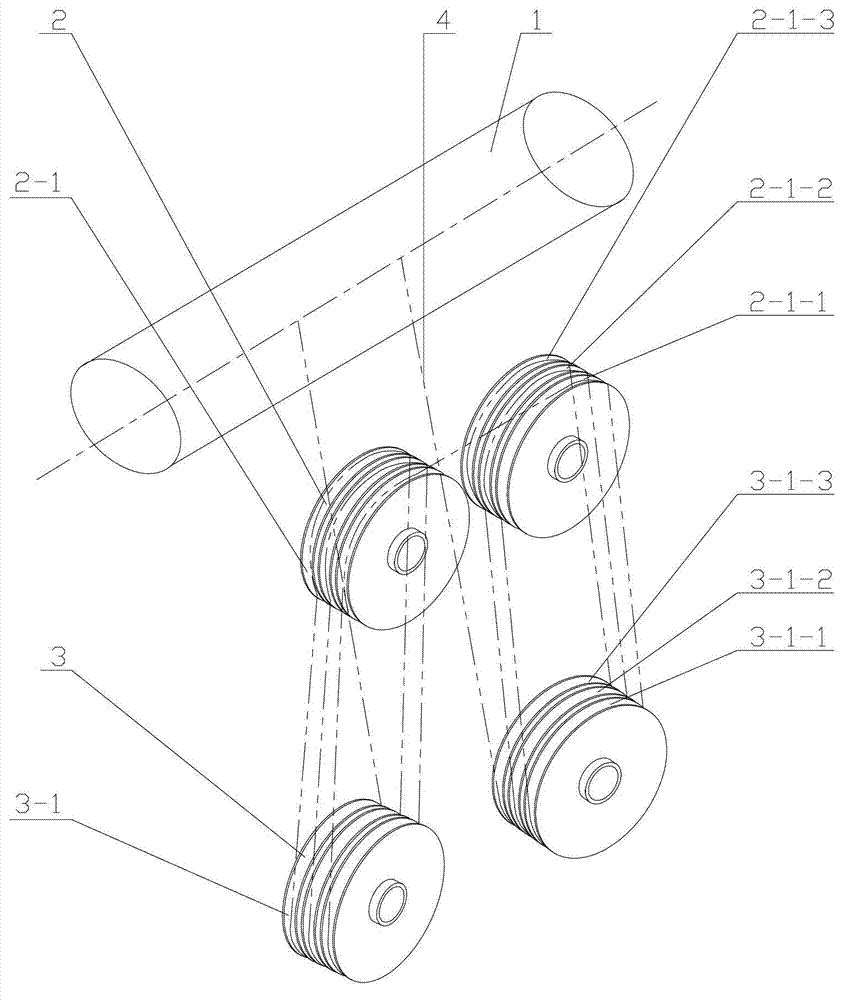

[0018] Such as figure 1 The hoisting device shown is suitable for hoisting on cranes, gantry cranes and hoists, etc. The hoisting device includes a motor-driven reel 1, an upper fixed pulley assembly 2 close to the reel 1 and a lower movable pulley assembly Into 3, the fixed pulley assembly 2 is composed of two fixed pulley blocks 2-1, the axial direction of the fixed pulley block 2-1 is perpendicular to the axial direction of the reel 1, and the movable pulley assembly 3 is composed of two axial directions in eight The font movable pulley block 3-1 is formed, and the hoisting device also has a hoisting rope 4, and the hoisting rope 4 spans the two fixed pulleys on the two fixed pulley blocks 2-1 that play a balancing role. 1 and the fixed pulley block 2-1 are wound sequentially, and finally wound upwards evenly on the reel 1 on the movable pulley block 3-1 and finally fixed on the left and right ends of the reel 1. Adopt the structure of two movable pulley blocks 3-1 of figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com