Novel chuck protecting device

A protection device and chuck technology, applied in maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of strangled chucks, inconvenient installation and disassembly of workpieces, etc., so as to reduce work intensity and improve The effect of processing productivity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described below in conjunction with accompanying drawing.

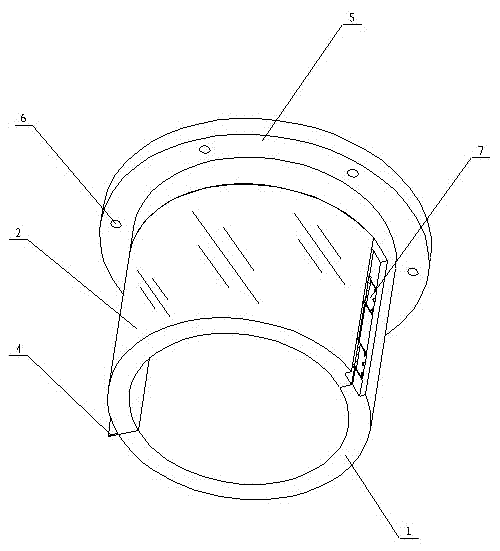

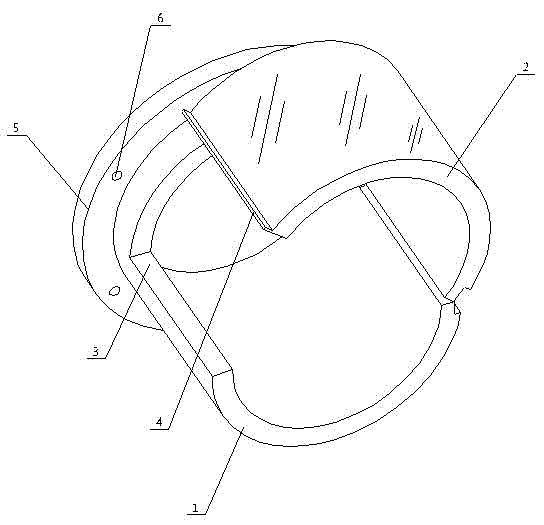

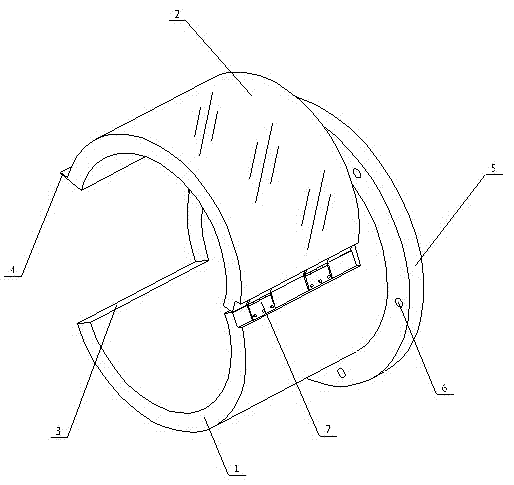

[0015] attached Figure 1-3 It is a new type of chuck protection device according to the present invention, which includes a sleeve body 1 and an upper cover 2; the sleeve body 1 is cylindrical, and on the rear end surface of the sleeve body 1, there are protrusions extending radially outward. Disk 5; a plurality of fixing holes 6 are evenly distributed on the convex disk 5; the sleeve body 1 is overcoated on the chuck, and fixed on the machine tool through the fixing holes 6 on the convex disk 5; the sleeve body 1 The front end of the sleeve body 1 is axially cut with a semi-annular groove 3; the semi-annular groove 3 is located directly above the sleeve body 1, and the length of the semi-annular groove 3 is longer than that on the chuck. The distance from the wrench hole to the clamping workpiece end; the upper cover 2 is matched with the semi-circular groove 3, and one end of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com