Underpants hip-full form hot-pressing molding machine

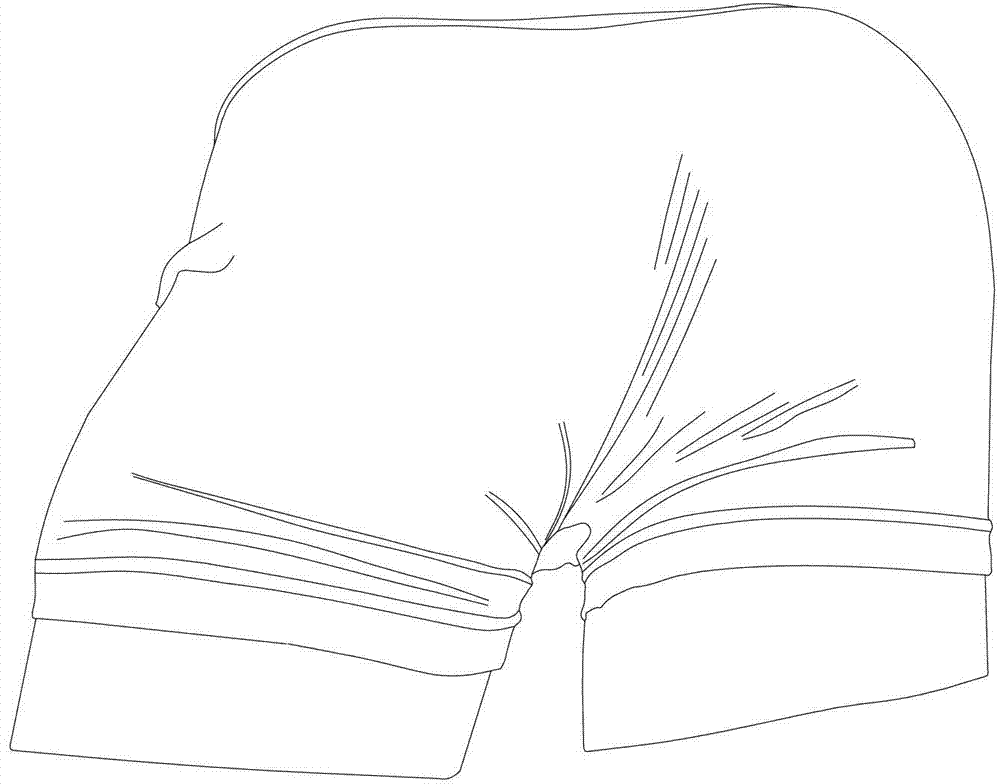

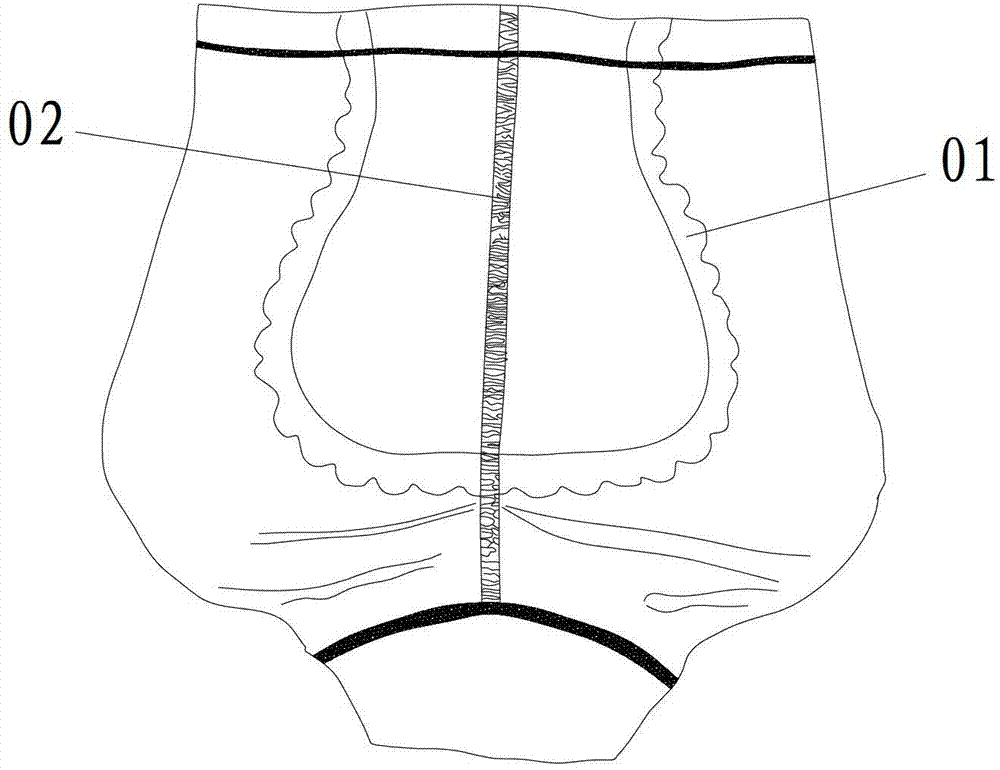

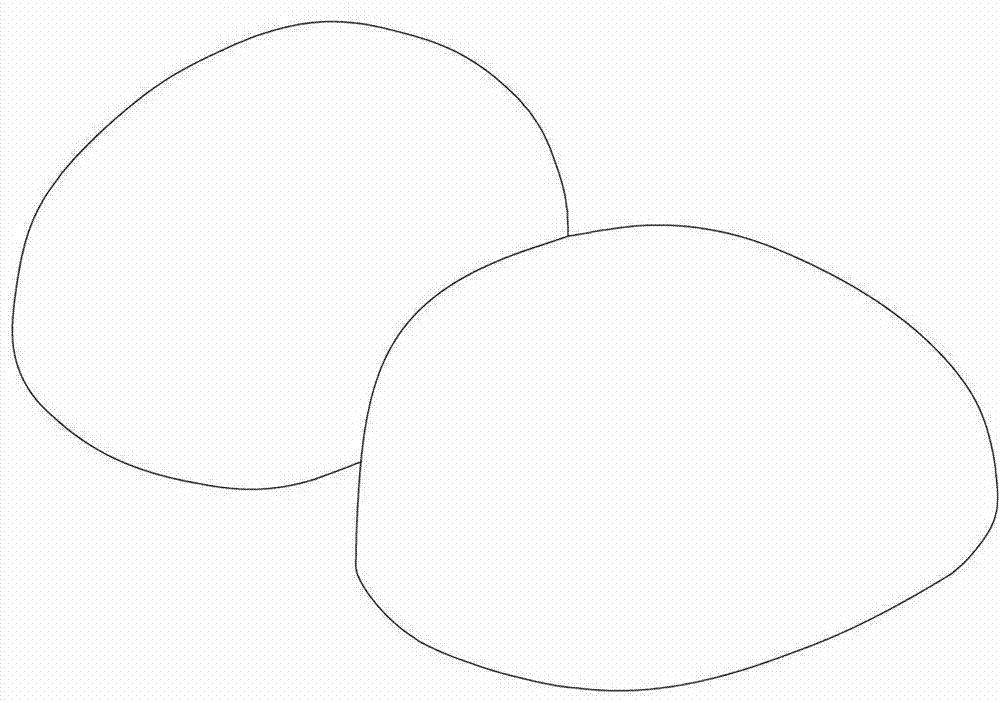

A molding machine and extrusion molding technology, which is applied in the field of clothing manufacturing, can solve problems such as wearing discomfort, losing the curve and beauty of the hips, and failing to achieve hip lifting and body shaping, so as to improve wearing comfort, save labor costs, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Such as image 3 , Figure 4 , Figure 5 and Figure 6 Shown, a kind of panties buttocks type thermocompression forming machine, it comprises machine platform 1, is provided with a buttocks mold 2 driven by the first air cylinder 7 on the machine platform, is provided with a heating plate 3 below the hips mold 2, and machine platform 1 also includes an upper platen 5 and a lower platen 6, the lower platen 6 is fixed on the machine platform 1, an upper oven 4 is connected above the upper platen 5, and the upper platen 5 and the upper oven 4 are driven 8 by a second cylinder. The upper pressing plate 5 and the lower pressing plate 6 form a passage 14 in the middle for the buttock mold to pass through.

[0037] When working, the upper pressing plate 5 and the lower pressing plate 6 are separated, and the cloth 9 is placed flat on the lower pressing plate 6, and the second cylinder 8 drives the upper pressing plate 5 to move downward, and the upper pressing plate 5 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com